The use of fluorescent fiber optic temperature monitoring system in switchgear is mainly due to the fact that this technology can provide high-precision and fast response temperature monitoring, with good insulation, anti electromagnetic interference ability and intrinsic safety, which can effectively prevent equipment damage and safety accidents caused by high temperature, and ensure the stable operation of the power system.

1、 Working principle of fluorescent fiber optic temperature monitoring system for switchgear

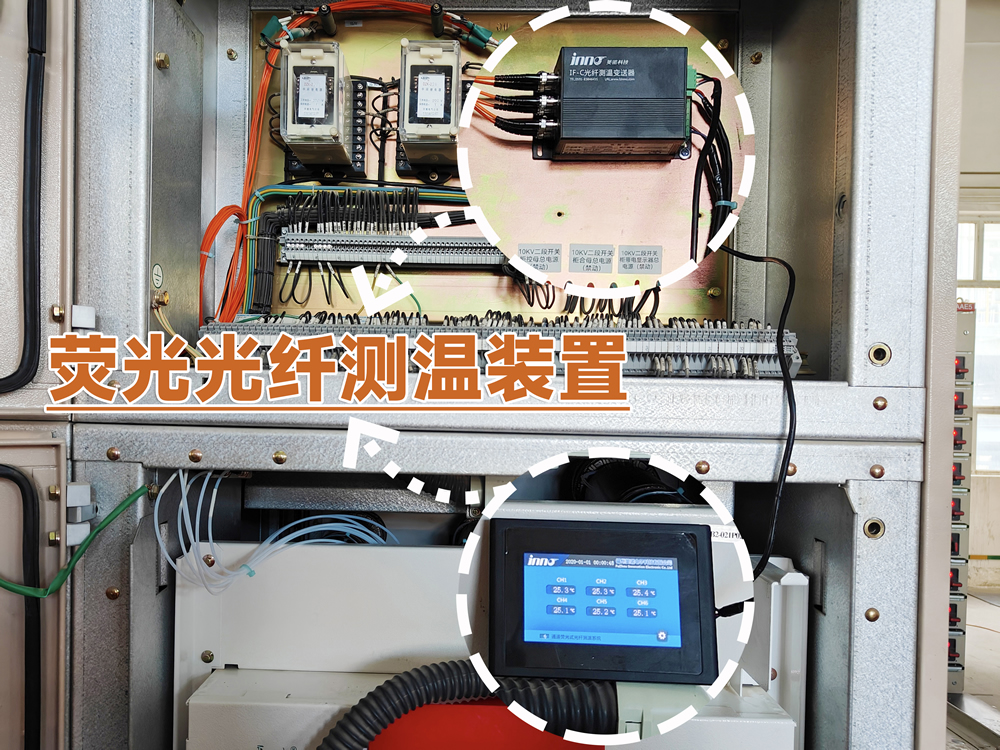

The switch cabinet fluorescent fiber optic temperature measurement system works based on fluorescent fiber optic temperature sensing technology. The specific principle is as follows: Firstly, the fiber optic sensing area in the system contains special fluorescent materials. When the system starts working, the laser will generate an optical signal to excite the fluorescent material in the fiber sensing area. Under the excitation of light signals, fluorescent materials will emit specific fluorescent signals. Moreover, fluorescent fiber optic sensors utilize the characteristics of fluorescent materials to measure temperature through changes in fiber loss and fluorescence intensity. Meanwhile, the system typically includes components such as a fluorescent fiber temperature demodulator and a fluorescent fiber temperature sensor. The excitation light source (such as LED or laser) generates a light signal, and the fluorescent fiber optic sensor can monitor the temperature inside the switchgear, such as real-time online monitoring and fault alarm of the contact temperature and cable joint temperature (multi-point) of the high-voltage switchgear, which is transmitted to the monitoring background through RS485 port for remote monitoring. Its temperature measurement range is -20~+150 ℃, with a temperature measurement accuracy of ± 1 ℃. It adopts contact measurement method and meets insulation requirements. The probe diameter is not greater than 3mm, and the temperature control system device has passed third-party withstand voltage test. The probe life is not less than 30 years.

2、 The advantages of using a fluorescent fiber optic temperature monitoring system for switchgear

2.1 Strong ability to resist electromagnetic interference

There is a strong electromagnetic field inside the switchgear, and the signal transmission medium of the fluorescent fiber optic temperature monitoring system is light. In this environment, as the optical signal is not affected by electromagnetic interference, the system can accurately measure temperature without measurement errors or signal transmission interruptions due to the complex electromagnetic environment inside the switchgear. This advantage enables the fluorescence fiber optic temperature monitoring system to work stably and reliably in high electromagnetic interference environments such as switchgear, thereby ensuring the accuracy and continuity of temperature monitoring for switchgear.

2.2 High Security

Fiber optic sensors themselves are non-conductive, which allows them to operate safely even in high-pressure environments. In switchgear, due to the involvement of high-voltage equipment, using a fluorescent fiber optic temperature monitoring system can avoid safety risks caused by sensor conductivity, such as electric shock accidents, short circuits, etc. This provides reliable protection for the safe operation of the switchgear and the personal safety of maintenance personnel, reducing safety hazards in the temperature monitoring process of the switchgear.

2.3 Can achieve multi-point measurement

A fiber optic temperature measurement device interface can connect multiple fluorescent sensors through multiple channels, allowing the system to achieve multi-point temperature measurement function. Inside the switchgear, different parts may have different temperature conditions, such as busbars, moving contacts, stationary contacts, and other key components that require temperature monitoring. Through multi-point measurement, the temperature distribution inside the switchgear can be comprehensively monitored, and abnormal temperature conditions in various parts can be detected in a timely manner, which helps to accurately evaluate the overall temperature condition of the switchgear and prevent faults.

2.4 Good long-term stability

Fluorescent fiber optic sensors have good long-term stability and reliability. This long-term stability means that the system can continuously and stably monitor temperature during long-term operation without frequent failures or performance degradation. Due to its good stability, it reduces the frequency and cost of system maintenance, saves manpower, material resources, and financial resources, and improves the economy and practicality of switchgear temperature monitoring.

2.5 High precision

The switch cabinet fluorescent fiber optic temperature sensor has high-precision temperature measurement capability. It can accurately detect small temperature changes inside the switchgear, which is of great significance for preventing overheating and faults in power equipment. During the operation of the switchgear, even a small temperature increase may indicate potential problems. High precision measurement can detect these subtle temperature changes in a timely manner, and take measures in advance to avoid equipment damage and safety accidents.

2.6 Fast response speed

The fluorescent fiber optic temperature sensor for switchgear using optical signal transmission and detection technology has a very fast response speed. When the temperature inside the switchgear changes, the sensor can detect this change in a timely manner and quickly issue an alarm signal in case of abnormal temperature. This rapid response capability helps to detect problems in a timely manner and take measures to prevent equipment damage due to overheating, ensuring the safe operation of switchgear and related power equipment.

3、 Application Case of Fluorescent Fiber Optic Temperature Monitoring System in Switchgear

3.1 Monitoring the temperature of the busbar

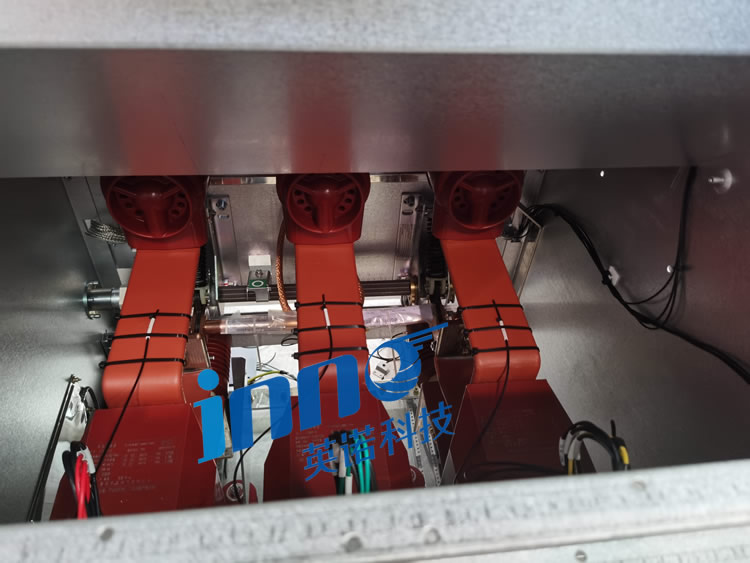

In high-voltage switchgear, the busbar is an important component responsible for the transmission of electrical energy. Due to the heat generated when current passes through the busbar, if the temperature of the busbar is too high, it may lead to a decrease in its performance and even cause safety accidents. The fluorescence fiber optic temperature measurement system can install fiber optic sensors on or near the surface of the busbar through contact monitoring, and monitor the temperature changes of the busbar in real time. Once the temperature of the busbar rises abnormally, the system can detect and issue an alarm in a timely manner, thereby preventing equipment failures caused by overheating of the busbar and ensuring the normal operation of the high-voltage switchgear.

3.2 Monitoring the temperature of moving and stationary contacts

The moving and stationary contacts play a crucial role in the opening and closing operation of the switchgear, and their contact directly affects the on/off of the circuit and the transmission efficiency of electrical energy. During the switch operation, heating may occur between the contacts due to poor contact, excessive current, and other reasons. The fluorescent fiber optic temperature measurement system can accurately monitor the temperature of the moving and stationary contacts. When the contact temperature exceeds the normal range, the system can issue a timely warning. For example, in a high-voltage switchgear of a certain power substation, after installing a fluorescent fiber optic temperature measurement system, an abnormal heating situation of the moving contact was successfully detected. Due to the timely alarm issued by the system, the staff were able to take measures quickly to avoid power failures that may be caused by contact overheating, ensuring the normal power supply of the substation.

3.3 Implement remote monitoring

The fluorescence fiber optic temperature measurement system can be used in conjunction with a remote monitoring system to achieve remote monitoring and data transmission of the internal temperature of the switchgear. In some large power systems, switchgear is distributed in different areas. Through remote monitoring functions, management and maintenance personnel can view the temperature data of each switchgear in real-time in the control center, without the need to inspect them one by one on site. For example, in a large photovoltaic power plant, there are numerous switch cabinets distributed. After adopting a fluorescent fiber optic temperature measurement system, the staff can remotely monitor the temperature of the switch cabinets in the central control room. Once there is an abnormal temperature, personnel can be arranged for timely maintenance, which improves operation and maintenance efficiency and reduces operation and maintenance costs.

4. Compared with other temperature measurement methods for switchgear, the advantages of fluorescent fiber optic temperature monitoring system

4.1 Compared with wireless temperature measurement methods/

Comparison of electromagnetic interference resistance

The wireless temperature measurement method has obvious disadvantages in the application of switchgear. Due to the strong electromagnetic field inside the switchgear, wireless signals are easily interfered with. This interference can affect the accuracy and stability of measurements, leading to deviations or loss of measurement data. The fluorescence fiber optic temperature monitoring system, due to its signal transmission relying on the optical signal in the fiber optic, is not affected by electromagnetic interference and can stably and accurately measure temperature in the strong electromagnetic environment of the switchgear.

Comparison of battery life and maintenance workload

Wireless sensors rely on battery power and have limited battery life, requiring regular battery replacement. In the case of a large number of switch cabinets, the workload of replacing batteries is relatively high, and if batteries cannot be replaced in a timely manner, it may lead to interruption of temperature monitoring. The fluorescence fiber optic temperature monitoring system does not require battery power supply, and there is no battery life issue, reducing maintenance workload and improving the reliability and sustainability of the system.

Comparison of Data Security

In power systems with high security requirements, there may be a risk of interception of wirelessly transmitted data. The signal transmission of the fluorescence fiber optic temperature monitoring system is based on optical fibers, which have high confidentiality and are not easily stolen during data transmission, ensuring the security of temperature monitoring data.

4.2 Compared with traditional infrared temperature measurement methods

Comparison of measurement accuracy

The traditional infrared temperature measurement method is easily affected by environmental factors, such as radiation from surrounding objects, measurement distance, measurement angle, etc., which can all affect the measurement results. The fluorescence fiber optic temperature monitoring system uses contact measurement to directly measure the temperature of the monitored object, resulting in more accurate and reliable measurement results. In the complex environment inside the switchgear, it is possible to more accurately monitor temperature changes in key areas such as busbars and contacts, avoiding misjudgment of equipment temperature status due to measurement errors.

Comparison of positioning accuracy

Infrared temperature measurement methods are often difficult to accurately determine the location of heat generation, especially in cases where the internal structure of the switchgear is complex and there are numerous components. The fluorescence fiber optic temperature monitoring system can accurately locate the hotspots by installing sensors at key locations. For example, when monitoring the temperature of the moving contact, if there is abnormal heating, the fluorescent fiber optic temperature measurement system can accurately indicate which moving contact has the problem, which facilitates timely maintenance and handling, reducing maintenance time and workload.

5. The necessity of using fluorescent fiber optic temperature monitoring system for switchgear

5.1 Working environment and temperature impact of switchgear

Switchgear is widely used in major power companies, photovoltaic power plants, thermal power plants and other places, and is a basic electrical equipment. The interior of the switchgear is equipped with many switches, instruments, and other devices, which generate a large amount of heat during operation. Especially for outdoor switchgear, the heating phenomenon is more obvious during peak loads and high temperatures in summer. Excessive temperature can cause damage to the electrical equipment inside the switchgear, such as shortening the service life of the equipment, reducing its performance, and even potentially causing equipment failure, leading to serious consequences such as power outages. Therefore, monitoring the temperature inside the switchgear is very necessary.

5.2 Shortcomings of Traditional Temperature Monitoring Methods for Switchgear

The traditional temperature monitoring method for switchgear has some shortcomings. For example, manual inspection is inefficient, unable to detect temperature anomalies in a timely manner, and relies on manual experience to make judgments, making accuracy difficult to guarantee. However, some existing temperature monitoring systems, such as those based on electrical signals, are susceptible to interference from the electromagnetic field inside the switchgear, resulting in inaccurate measurements or false alarms. In addition, some monitoring systems are not precise enough in locating the heating location, and when temperature anomalies occur, they cannot quickly and accurately determine the fault point, delaying maintenance time. Moreover, if some systems experience local failures, it is difficult for users to detect them in a timely manner, which not only wastes personnel’s energy but also poses safety hazards.

5.3 Advantages and Adaptability of Fluorescent Fiber Optic Temperature Monitoring System

The fluorescence fiber optic temperature monitoring system can precisely compensate for the shortcomings of traditional switchgear temperature monitoring methods. It has many advantages such as anti electromagnetic interference, high precision, fast response, multi-point measurement, and good long-term stability. In a complex environment like a switchgear, it is possible to accurately monitor the temperature of various key parts, detect temperature anomalies in a timely manner and issue alarms, accurately locate hot spots, and reduce maintenance costs due to its good stability. These advantages make the fluorescent fiber optic temperature monitoring system very suitable for temperature monitoring of switchgear, which can effectively improve the safety and reliability of switchgear and ensure the stable operation of the power system.

Fiber optic temperature sensor, Intelligent monitoring system, Distributed fiber optic manufacturer in China

|

|

|

INNO fibre optic temperature sensors ,temperature monitoring systems.

INNO fibre optic temperature sensors ,temperature monitoring systems.