The temperature monitoring of power equipment uses fiber optic temperature measurement technology, which utilizes the high precision, high sensitivity, strong anti-interference ability, safety and reliability of optical fibers to monitor the temperature of power equipment such as switchgear, ring main unit, dry-type transformer, oil immersed transformer, etc. through sensors such as fluorescent optical fibers, achieving accurate, stable and long-term monitoring of equipment temperature, timely detecting abnormal situations such as equipment overheating, and ensuring the safe and stable operation of the power system.

1. Monitoring of electrical connection points

1.1 Connecting point of busbar in high and low voltage switchgear

In the power system, the busbar plays an important role in collecting and distributing electrical energy. If there is a poor connection at the busbar overlap point, such as loose bolts, surface oxidation, etc., it will cause an increase in contact resistance and heat generation. Long term overheating may cause a decrease in the performance of the metal materials in the busbar, and even lead to short-circuit faults. Through temperature monitoring, these abnormal temperature increases can be detected in a timely manner, and measures can be taken to prevent malfunctions from occurring. For example, in the distribution rooms of some large industrial enterprises, the busbar is subjected to high currents for a long time. Without effective temperature monitoring, if there is a problem with the busbar connection point, it may lead to a power outage in the entire workshop, affecting production progress.

1.2 Circuit breaker contacts

Circuit breakers are used in power systems to cut off and connect circuits. The contact will generate an arc during the opening and closing process, and it must pass through the rated current during normal operation. If the contact pressure of the contact is insufficient, the surface is worn, or there is dirt, it will increase the contact resistance of the contact and generate heat. Monitoring the temperature of circuit breaker contacts can promptly detect abnormal heating of the contacts, avoiding faults such as contact burnout and adhesion caused by overheating, thereby ensuring the normal operation of the circuit breaker. The normal operation of circuit breakers in substations is crucial for the stability of the entire power grid, and temperature monitoring can improve the reliability of circuit breakers.

1.3 Cable connectors

Cable joints are weak links in cable circuits. In the process of cable production and installation, if the process is not up to standard, such as loose crimping, improper insulation treatment, etc., it will cause an increase in resistance at the joint and generate heat. And cable joints are usually located in concealed positions, which are not easy to observe directly. Temperature monitoring can detect overheating of cable joints in a timely manner, preventing accidents such as cable insulation damage, short circuits, and even fires caused by overheating. For example, in the urban power cable network, a large number of cable joints are distributed in underground cable wells and other locations. The temperature monitoring system can remotely and real-time monitor the temperature of these joints to ensure the safety of urban power supply.

2. Monitoring of the main body of power equipment

2.1 Transformer

Both dry-type transformers and oil immersed transformers generate heat during operation. Dry type transformers mainly rely on air convection for heat dissipation, while oil immersed transformers rely on oil circulation for heat dissipation. If the load on the transformer is too large, the cooling system fails, or there is a local short circuit inside, it can all cause the temperature of the transformer to rise. Excessive temperature of transformers can accelerate the aging of insulation materials, reduce the service life of transformers, and in severe cases, cause transformer failures or even explosions. Through temperature monitoring, the temperature distribution of the transformer can be understood, and the load can be adjusted or the cooling system can be maintained in a timely manner to ensure the safe and stable operation of the transformer. In power substations, transformers are the core equipment, and their normal operation is related to the power supply capacity and reliability of the entire substation.

2.2 Switchgear and Ring Main Unit

The switchgear and ring main unit contain various electrical components and connection points inside. During operation, local temperature rise may occur due to aging of components, poor connections, or overload. Temperature monitoring can comprehensively grasp the temperature conditions inside the switchgear and ring main unit, timely detect abnormal hotspots, prevent electrical component damage, short circuits and other problems caused by high temperature, ensure the normal operation of the switchgear and ring main unit, and improve the continuity and safety of power supply. In urban distribution networks, ring main units are widely used for cable branching and interconnection, and their operational reliability directly affects the power supply of surrounding users.

3. Other devices and environmental temperature monitoring

3.1 Surface and Internal Winding of Electric Motor

When the electric motor is running, the current passing through the winding will generate Joule heat. If the motor is overloaded, loses phase, or the bearings are damaged, it will cause the temperature of the motor to rise. Monitoring the temperature of the surface and internal windings of the motor can promptly detect abnormal operating conditions and prevent the motor from burning out due to overheating. Temperature monitoring can help improve the service life and operational efficiency of various electric motor equipment in industrial production, such as drive motors for large production equipment in factories and compressor motors for air conditioning systems.

3.2 Cable trays and longer cables

If the cables in the cable tray are arranged too densely, with poor ventilation, or if there are insulation aging issues with the cables themselves, it may lead to an increase in temperature. For temperature monitoring of longer cables, abnormal temperature conditions during operation can be detected in a timely manner to prevent cable failures. Temperature monitoring can ensure the safe operation of cables and avoid power outages caused by cable failures in cable trays and long cable lines in some large buildings or industrial plants.

3.3 Temperature inside the cabinet

The ambient temperature inside the switchgear and ring main unit also affects the operation of the equipment. If the temperature inside the cabinet is too high, it will affect the performance and lifespan of electrical components. By monitoring the temperature inside the cabinet, the ventilation and heat dissipation system can be adjusted reasonably to ensure that the equipment inside the cabinet operates in a suitable temperature environment. For example, in the high temperature environment of summer, if the electrical components inside the cabinet do not have a good heat dissipation environment, they are prone to malfunction. Environmental temperature monitoring can detect and solve this problem in a timely manner.

Fiber optic temperature measurement is an advanced temperature measurement technology with many advantages.

1. High precision and high sensitivity

1.1 Accurate measurement

Fiber optic temperature measurement technology can achieve high-precision temperature measurement. For example, a distributed fiber optic temperature measurement system can achieve a temperature measurement accuracy of ± 1 ℃ and accurately detect small temperature changes. In some power equipment monitoring that is very sensitive to temperature changes, such as temperature monitoring of internal windings of transformers, this high-precision measurement capability can detect abnormal temperature fluctuations in a timely manner, and take measures in advance to prevent faults from occurring. For some power equipment in high-precision industrial production processes, such as power supply equipment in semiconductor manufacturing workshops, the high precision of fiber optic temperature measurement can meet their strict temperature control requirements.

1.2 High sensitivity

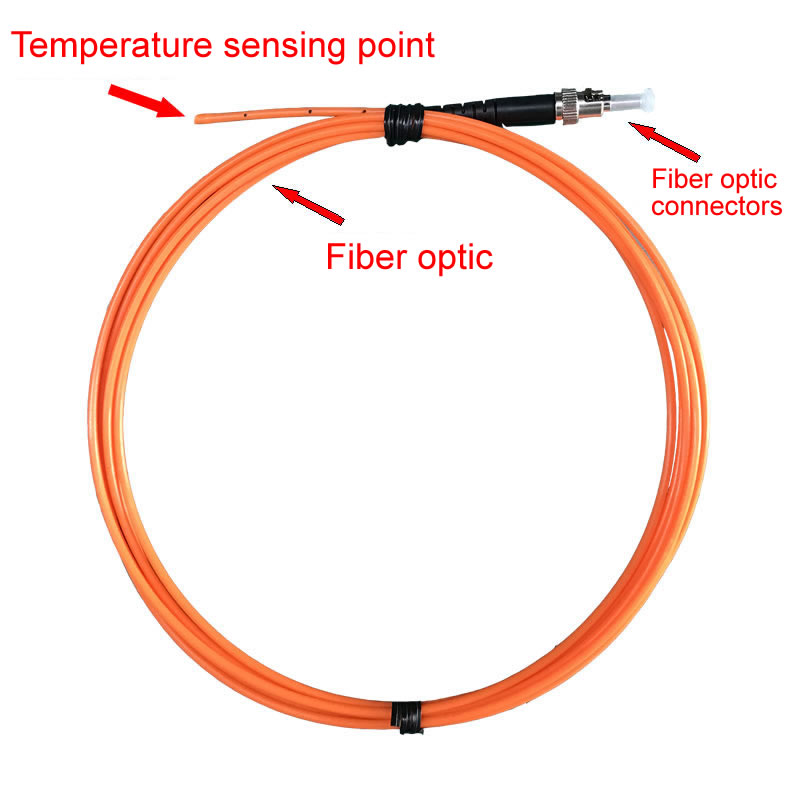

The physical properties of optical fibers themselves make fiber optic temperature measurement highly sensitive. Fiber optic temperature sensors can quickly respond to temperature changes, such as fluorescent fiber optic sensors, which measure temperature by detecting the lifetime of fluorescence. Fluorescence lifetime decreases with increasing temperature, and this fluorescence based measurement method is very sensitive to temperature changes. In power equipment, when abnormal situations such as local overheating occur at the beginning of the equipment, fiber optic temperature sensors can quickly sense the slight increase in temperature and issue alarm signals in a timely manner, which is crucial for ensuring the safe operation of power equipment.

2. Strong anti-interference ability

2.1 Electromagnetic interference immunity

Fiber optic is composed of quartz material and is completely electrically insulated. In the high electromagnetic environment of the power system, fiber optic temperature measurement is not affected by external electromagnetic interference. For example, in substations, there are a large number of high-voltage equipment, transformers, reactors, etc., surrounded by strong electromagnetic fields. Traditional electrical temperature sensors may be affected by these electromagnetic fields, resulting in inaccurate measurement data. And the fiber optic temperature measurement system, whether it is fiber optic grating temperature measurement or fluorescent fiber optic temperature measurement, its signal transmission is completely based on fiber optic and will not be affected by electromagnetic interference, which can stably and accurately measure the temperature of power equipment.

2.2 Corrosion resistance and chemical stability

Fiber optic materials have good corrosion resistance. In some harsh industrial environments, such as near power equipment in chemical enterprises, there may be corrosive gases or liquids, and fiber optic temperature sensors can work normally. Its chemical stability allows the fiber optic sensor to be used for a long time in different chemical environments without being damaged by corrosion, ensuring the long-term reliability of temperature monitoring.

3. Safe and reliable

3.1 Intrinsic Safety

The fiber optic temperature measurement system uses fiber optic as the sensing and transmission medium. Fiber optic transmits optical signals without current passing through, making it very safe to use in hazardous environments such as flammable and explosive environments. For example, in the power system of petrochemical enterprises, there are a large number of flammable and explosive substances. Using fiber optic temperature measurement can avoid safety accidents caused by electric sparks that may be generated by electrical sensors, and achieve intrinsic safety temperature monitoring.

3.2 High reliability

The material of optical fiber is generally quartz glass, which has the characteristics of non corrosion, fire resistance, water resistance, and long service life. It can usually serve for 30 years. The sensors and optical fibers in the fiber optic temperature measurement system have high reliability, reducing the risk of temperature monitoring interruption caused by sensor failures. During the long-term operation of power equipment, this highly reliable temperature monitoring system can work continuously and stably, providing reliable temperature data support for equipment maintenance and management.

4. Suitable for special environments and long-distance monitoring

4.1 High temperature environment measurement

Fiber optic sensors can measure in high-temperature environments and are suitable for managing high-temperature equipment such as transformers and generators. In some large power equipment, such as generator sets in thermal power plants, high temperatures are generated during equipment operation. Fiber optic temperature sensors can accurately measure temperature in high temperature environments without experiencing performance degradation or damage at high temperatures like some traditional temperature sensors.

4.2 Long distance transmission

The two prominent advantages of optical fiber are the large amount of transmitted data and low loss, which can achieve remote monitoring for tens of kilometers without the need for relays. In the power system, for some widely distributed power equipment, such as long-distance transmission lines, fiber optic temperature measurement systems can transmit temperature data from various monitoring points to the monitoring center through optical fibers, achieving centralized temperature monitoring and management of long-distance power equipment.

5. Can achieve distributed measurement

5.1 Multi point measurement capability

Distributed fiber optic temperature measurement technology can perform multi-point measurements with high spatial and temporal resolution, enabling precise understanding of temperature distribution. For example, in large power plants or substations, there are a large number of electrical equipment and connection points that require temperature monitoring. The distributed fiber optic temperature measurement system can connect hundreds or thousands of sensors in series to monitor measurement points within a range of several kilometers along the line in real time, with a density of measurement points up to meters. This distributed measurement capability can comprehensively and accurately grasp the temperature distribution of power equipment in the entire area, and timely detect potential overheating areas or fault points.

5.2 Continuous monitoring

The distributed fiber optic temperature measurement system can achieve continuous temperature monitoring, and temperature information can be continuously obtained along the fiber optic cable. For long-term operation monitoring of power equipment, this continuous monitoring capability can provide a complete curve of equipment temperature changes, which helps analyze the operating status of the equipment and predict the trend of equipment failures. For example, for the temperature monitoring of transformer windings, continuous temperature monitoring data can be used to understand the temperature changes of transformers under different loads and environmental temperatures, providing a basis for the maintenance and optimized operation of transformers.

The application advantages of fluorescent optical fiber in temperature monitoring of switchgear/ring main unit

1. High precision and stability

1.1 Accurate measurement

Fluorescent optical fibers have high temperature measurement accuracy in switchgear/ring main unit temperature monitoring. For example, its temperature measurement accuracy can reach ± 1 ℃, and it can accurately detect temperature changes of electrical connection points and components inside the switchgear/ring main unit. Small temperature changes at the contact and busbar connection points in the switchgear may indicate potential faults, and high-precision measurement of fluorescent optical fibers can detect these abnormalities in a timely manner. In the ring main unit, temperature monitoring at cable joints and other locations also requires high precision. Fluorescent optical fibers can meet this requirement, accurately reflecting temperature conditions and providing reliable data basis for equipment maintenance and operation management.

1.2 Long term stable operation

Fluorescent fiber optic sensors have long-term stable and reliable operating characteristics. The fluorescent substances and fiber optic materials used have good stability and are not easily affected by long-term environmental factors. In long-term operating equipment environments such as switchgear/ring main unit, fluorescent optical fibers can continuously and stably monitor temperature. For example, in a switchgear in a continuously operating substation for many years, a fluorescent fiber optic temperature monitoring system can consistently and accurately measure temperature, reducing the risk of misjudgment caused by sensor performance fluctuations.

2. Excellent anti-interference performance

2.1 Electromagnetic interference immunity

The signal transmission of the fluorescence fiber optic temperature measurement system is based on optical fibers, which are electrically insulated and therefore completely free from electromagnetic interference. There are various electromagnetic fields generated by electrical components inside the switchgear/ring main unit, such as electromagnetic pulses generated by the opening and closing operation of circuit breakers. Fluorescent optical fibers can accurately measure temperature in such electromagnetic environments without data fluctuations or measurement errors. For ring main units, especially in urban distribution networks, there may be various electromagnetic interference sources around them, such as other power equipment, communication equipment, etc. The electromagnetic interference immunity characteristics of fluorescent optical fibers ensure the accuracy of temperature monitoring.

2.2 Anti creepage and anti pollution flashover

Fluorescent optical fibers have the characteristics of anti creepage and anti pollution flashover in switchgear/ring main unit. The internal environment of switchgear/ring main unit is relatively complex, and there may be dust, moisture, and other conditions. Fluorescent fiber optic probes can be safely used in such environments without affecting temperature measurement due to creepage or pollution flashover phenomena. For example, in some switchgear rooms with poor industrial environments, fluorescent optical fibers can work normally without the possibility of sensor damage or inaccurate measurement caused by insufficient creepage distance or pollution flashover like some traditional electrical sensors.

3. Safety and adaptability

3.1 High Voltage Resistance/

Fluorescent optical fiber has the characteristic of high voltage resistance in temperature monitoring of switchgear/ring main unit. For example, its fiber optic probe can withstand a voltage of up to 100KV (40mm withstand length, 5-minute withstand time), which allows it to directly monitor the temperature of electrical connection points in high-voltage environments such as switchgear/ring main unit. In high-voltage switchgear, the contacts and busbars are in a high voltage state, and fluorescent optical fibers can safely approach these areas for temperature measurement without being damaged by high voltage, ensuring the effectiveness and safety of temperature monitoring.

3.2 Intrinsic Safety

The fluorescence fiber optic temperature measurement system uses fiber optic transmission to transmit optical signals, without electricity or current, so it has inherent safety characteristics in equipment environments such as switchgear/ring main unit that may have flammable and explosive risks. For example, in the switchgear/ring main unit of some chemical companies’ distribution rooms, the use of fluorescent fiber temperature monitoring systems will not cause dangerous factors such as electric sparks due to the sensors themselves, thereby improving the safety of equipment operation.

4. Easy to integrate and intelligentize

4.1 Multiple communication interfaces

The fluorescence fiber optic temperature measurement system has RS485 and fiber optic communication interfaces, supporting MODBUS and IEC61850 communication protocols. This makes it easy to integrate with other intelligent devices of switchgear/ring main unit, achieving data sharing and interaction. In intelligent substations, switch cabinets/ring main units need to communicate with monitoring systems, protection devices, etc. The various communication interfaces of the fluorescent fiber optic temperature measurement system can meet this integration requirement, making it easy to build an intelligent power equipment monitoring system.

4.2 Backend system and dedicated software support

The fluorescence fiber optic temperature measurement system can provide a backend system and dedicated software. These backend systems and specialized software can display real-time temperature information of each contact of the switchgear/ring main unit, including real-time curves, and can also store historical data of temperature information of each contact in the past month. Through software, various diagnostic methods can also be used to analyze the health status of equipment, such as analyzing all equipment parameter limit alarms and other judgment methods, to monitor the operation status of switchgear/ring main unit in a timely manner. At the same time, the system can automatically and manually generate various periodic reports, which can be exported and printed, making it convenient for equipment maintenance personnel to manage equipment and analyze faults.

The application advantages of fluorescent optical fiber in temperature monitoring of dry-type transformers/oil immersed transformers

1. Adapt to special environments

1.1 High voltage resistance and electromagnetic interference resistance

In the operating environment of dry-type transformers and oil immersed transformers, there are high voltages and strong electromagnetic interference. Fluorescent fiber optic sensors have strong resistance to electromagnetic interference, avoiding the problems of contact thermal resistance and temperature measurement limitations of traditional temperature measurement methods. For oil immersed transformers, the internal environment is high voltage, and fluorescent fiber optic sensors can work normally and accurately measure temperature. For example, in some 500kV oil immersed transformers, fluorescent fiber optic sensors have been successfully applied to monitor temperature distribution, solving the problem of real-time temperature monitoring inside the transformer due to the limitations of the high-voltage environment. In dry-type transformers, although the voltage level is relatively low, there is still electromagnetic interference, and fluorescent fiber optic sensors can perform temperature monitoring without interference.

1.2 Suitable for complex internal environments

Oil immersed transformers are filled with transformer oil, while dry-type transformers have special insulation and heat dissipation structures inside. The material of fluorescent fiber optic sensors has insulation properties, making them suitable for temperature measurement in these complex internal environments. For example, in the temperature monitoring of oil immersed transformers, fluorescent fiber optic sensors can be directly installed at the hot spot position of the winding to accurately measure the temperature. For dry-type transformers, the temperature control box shell, signal input terminal, and power supply adopt isolation and shielding technology from external electrical interference signals. Fluorescent fiber optic sensors can adapt to this environment and work stably.

2. High precision measurement

2.1 High temperature measurement accuracy

Fluorescent fiber can achieve high temperature measurement accuracy when used for temperature monitoring of dry-type transformers/oil immersed transformers. For fluorescent fiber temperature measurement of oil immersed transformer windings, the accuracy can reach 0.1 degrees. This high-precision temperature measurement is very important for the operation and management of transformers. During the operation of a transformer, small changes in winding temperature may indicate changes in the transformer’s load, insulation aging, or other potential issues. For example, when the load on a transformer increases slightly, the temperature of the winding will rise. If this temperature change can be accurately measured through fluorescent optical fibers, the load on the transformer can be adjusted in a timely manner to avoid insulation damage and other faults caused by overheating.

2.2 Comprehensive and accurate monitoring

Fluorescent fiber technology can achieve comprehensive temperature measurement of transformer windings without being affected by local faults or complex working conditions. Whether it is a dry-type transformer or an oil immersed transformer, the temperature distribution inside is uneven, and there may be local overheating. Fluorescent fiber optic sensors can accurately measure the temperature at different locations, achieving comprehensive monitoring of the internal temperature of transformers. For example, in oil immersed transformers, installing fluorescent fiber optic sensors in different parts such as windings, iron cores, and oil can comprehensively grasp the temperature inside the transformer, timely detect potential overheating areas, and ensure the safe operation of the transformer.

3. Long term reliability/

3.1 Long sensor lifespan

The lifespan of fluorescent fiber optic temperature probes is long, for example, in some applications, the lifespan of sensors can reach 30 years. In long-term operating equipment such as dry-type transformers and oil immersed transformers, the long lifespan of sensors means reduced maintenance and replacement costs for the equipment. For some transformers in large substations, once a fluorescent fiber temperature monitoring system is installed, there is no need to replace them for a long time due to sensor lifespan issues, ensuring the continuity and stability of temperature monitoring.

3.2 Stable temperature monitoring/

Fluorescent fiber optic sensors can provide stable temperature monitoring during long-term operation. It is based on the relationship between fluorescence signal and temperature for measurement, and this measurement method is relatively stable, without significant measurement errors due to the passage of time or small changes in the environment. In the daily operation of dry-type transformers/oil immersed transformers, whether in different seasons, load changes, or environmental temperature fluctuations, fluorescent fiber optic sensors can stably measure temperature, providing reliable data support for the operation and management of transformers.

Fiber optic temperature sensor, Intelligent monitoring system, Distributed fiber optic manufacturer in China

|

|

|

INNO fibre optic temperature sensors ,temperature monitoring systems.

INNO fibre optic temperature sensors ,temperature monitoring systems.