Why do high-voltage switchgear need temperature measurement

With the development of power technology, high-voltage and ultra-high voltage distribution networks are increasingly appearing in major power grids. As important electrical equipment, high-voltage switchgear can cause overheating and serious fire accidents due to aging contacts and increased contact resistance during long-term operation. In recent years, multiple incidents of switchgear overheating have occurred in power plants and substations, resulting in fires and widespread power outages. Solving the problem of switchgear overheating is the key to preventing such accidents from occurring. With the rapid progress of power technology, the transmission and distribution system is gradually developing towards technology, safety, and intelligence. In practical use, unpredictable accidents often occur due to factors such as the professional quality of installation personnel, uneven quality of cable accessories, and harsh environment.

Why does the high-voltage switchgear busbar measure temperature

In power switchgear, the busbar is an important component for transmitting current. Due to its resistance, it will generate heat when transmitting current, especially when transmitting large currents, it will generate a significant temperature rise. When the temperature rise of the busbar exceeds a certain value, it may cause switchgear faults, and in severe cases, it may also cause fires, causing significant losses to the distribution system. It is necessary to monitor the working temperature of the switchgear busbar in response to the above issues.

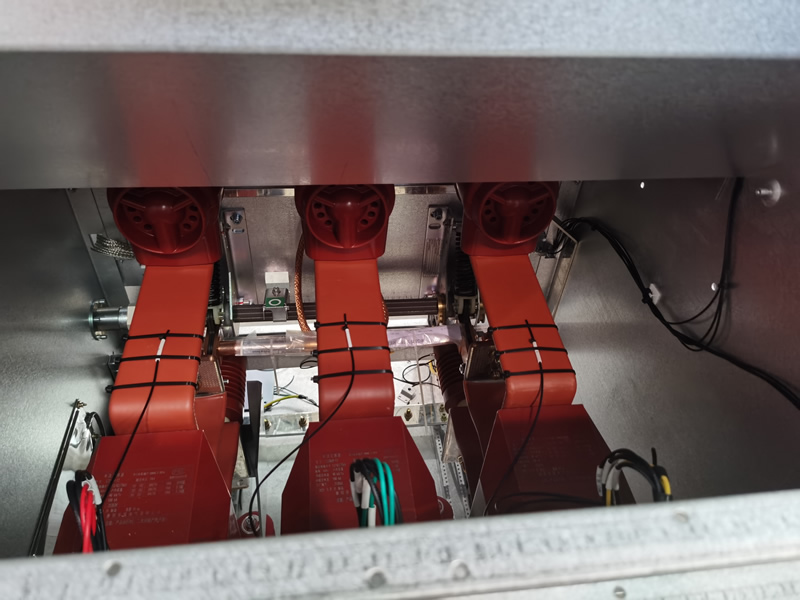

The contact parts of the busbar in high and low voltage switchgear often generate heat due to aging, loose bolts, or poor contact, resulting in excessive contact resistance. If the temperature of these heating parts cannot be monitored in real time, it is easy to cause equipment burning or sudden power outages and other accidents. The busbar is an important component of circuit connections, and current flows through it. Before the accident, abnormal current or heating at the fault point can cause an increase in the temperature of the busbar. At this point, if there is an intelligent temperature measurement system that can measure the temperature of the busbar, it can provide early warning and prevent potential problems. Although manual inspection of the operation of the switchgear can effectively prevent accidents caused by its heating, there is exposed high voltage inside the switchgear and the space is limited, making it impossible to conduct manual inspection and temperature measurement. Дар айни ҳол, monitoring the contact temperature inside the switchgear can effectively prevent accidents from occurring. Аммо, due to the high-voltage structure inside the switchgear, manual inspection and temperature measurement are not effective. New switchgear busbars are equipped with protective covers and infrared temperature guns are used, making it impossible to measure temperature from the observation window. The usual temperature measurement methods cannot be used.

Online monitoring system for fiber optic temperature of switchgear busbar

Using a suitable temperature measurement system to measure the temperature of the busbar, especially at points 3 ё 6 of the overlap, and conducting real-time online monitoring of the temperature of the busbar. Before an accident occurs, abnormal current or heating at the fault point can cause the temperature of the busbar to rise. Through the fiber optic intelligent temperature measurement system, the temperature of the busbar can be measured, which can provide early warning and prevent potential problems. Fluorescent fiber optic temperature measurement is a very good implementation plan. Дар fluorescent fiber optic temperature measurement device includes a fluorescent fiber optic temperature sensor probe installed at the busbar. The fiber optic temperature sensor transmits the temperature data sensed to the temperature transmitter, so that the staff can timely know the temperature at the busbar overlap. The temperature sensor has high measurement accuracy and can be widely promoted and applied in the temperature measurement technology of power equipment. Accurate reading and high reliability. The fiber optic sensor undergoes special processing inside, which not only has good insulation but also strong resistance to electromagnetic interference, ensuring the reliability and safety of equipment operation without any interference or impact on power equipment.

Сенсори ҳарорати нахи оптикӣ, Системаи интеллектуалии мониторинг, Истеҳсолкунандаи нахи оптикӣ дар Чин

|

|

|

Сенсорҳои ҳарорати нахи оптикии INNO ,системаҳои мониторинги ҳарорат.

Сенсорҳои ҳарорати нахи оптикии INNO ,системаҳои мониторинги ҳарорат.

WhatsApp

Барои оғоз кардани сӯҳбати WhatsApp бо мо рамзи QR-ро скан кунед.