The advantages of using fiber optic temperature measurement for switchgear temperature monitoring are its high voltage resistance, inherent insulation, strong electromagnetic interference resistance, high safety performance, long-distance signal transmission, fast response speed, high-precision measurement, Bekväm installation, and reasonable price.

1. Location for temperature monitoring of switchgear

There are multiple locations within the switchgear that require temperature monitoring, most of which are electrical connection points that are prone to overheating during operation.

1.1. Copper busbar connection points

The copper busbar connection point is an important part for current transmission inside the switchgear. During normal operation, current is distributed and transmitted through the copper busbar. Due to the high current, if there is poor contact at the connection point, it will cause an increase in resistance and generate heat. Till exempel, in the switchgear of some large substations, the current transmitted by the copper busbar may reach thousands of amperes, and even a small increase in contact resistance can significantly raise the temperature at the connection point. Once the temperature is too high, it may affect the conductivity of the busbar copper bar and even cause safety accidents, so temperature monitoring is necessary.

1.2. Connection points for the dynamic and static contacts of the handcart

The connection status of the dynamic and static contacts in the handcart switchgear is crucial for the normal operation of the equipment. When the handcart is pushed into the switchgear and connected to the static contact, current will conduct through this contact surface. During the process of closing and opening, friction and wear may occur between the moving and stationary contacts, or due to improper assembly or oxidation of the contact surface, the contact resistance may increase, resulting in an increase in temperature. If this temperature rise is not detected in a timely manner, it may further deteriorate the contact condition of the contacts, and in severe cases, cause the contacts to burn out, affecting the normal operation of the switchgear. Därför, this is also a key part of temperature monitoring.

1.3 Copper bars and cable connection points

Copper bars and cable connection points are the connection hubs between different electrical components inside the switchgear. The cable introduces external power into the switchgear and distributes power through copper bars. This connection point may also generate heat due to poor contact caused by construction techniques, long-term vibration, corrosion, and other factors. Especially in the distribution room switchgear of some industrial plants or high-rise buildings, there are numerous connection points between cables and copper bars. Any abnormal temperature at any connection point may affect the stability of the entire power supply system, so temperature monitoring must be carried out on these parts.

2. The benefits of using fiber optic temperature measurement for switchgear temperature monitoring

2.1 Strong ability to resist electromagnetic interference

The interior of the switchgear is a strong electromagnetic environment with a large number of electromagnetic interference sources. Equipment such as current transformers and voltage transformers generate high-intensity electromagnetic fields during operation. Fiber optic itself is made of glass or plastic, non-conductive, and not affected by electromagnetic fields. When using fiber optic temperature measurement, whether during signal transmission or sensor operation, it can operate stably in the strong electromagnetic environment of the switchgear, accurately measure temperature, and avoid measurement errors or signal transmission interruptions due to electromagnetic interference like some electronic sensors. Till exempel, in a substation, numerous electrical equipment operate simultaneously, and the electromagnetic field is very complex. The characteristic of fiber optic temperature measurement technology enables it to reliably monitor the temperature of the switchgear.

2.2 High safety performance

Fiber optic sensors do not generate electromagnetic radiation or sparks. Electromagnetic radiation generated inside enclosed and high voltage, high current equipment such as switchgear may cause interference to surrounding electronic devices, while sparks may lead to serious accidents such as electrical fires or explosions. Especially in some places with extremely high safety requirements, such as the switchgear in the distribution room of petrochemical enterprises, there are flammable and explosive hazardous substances. The use of fiber optic temperature measurement technology can effectively avoid the safety risks caused by the temperature measurement equipment itself and ensure the safety of equipment and personnel.

2.3 High voltage resistance

Fluorescent fiber optic temperature measurement products have high voltage resistance, with a voltage resistance greater than 100KV. This allows it to directly measure temperature in high voltage environments. Till exempel, in the temperature monitoring of equipment in ultra-high voltage substations, when facing high voltage environments exceeding 100KV, the end of the fluorescent fiber can make zero distance contact with the equipment for temperature measurement without being affected by high voltage, ensuring the normal operation of measurement work and providing important temperature data support for the safe operation of power equipment.

2.3 Fast response speed

Fiber optic temperature measurement technology can quickly respond to temperature changes. During the operation of the switchgear, if a connection point suddenly overheats, the fiber optic temperature measurement system can detect the rising trend of temperature in a timely manner and quickly transmit data to the monitoring system. In this way, operation and maintenance personnel can obtain information on temperature anomalies in the shortest possible time, take timely measures to prevent further deterioration of overheating problems, and ensure the normal operation of the switchgear. Till exempel, when the copper busbar connection point in the switchgear starts to heat up due to the early effects of a short circuit fault, the fiber optic temperature measurement system can quickly detect the temperature change and sound an alarm, buying time for fault diagnosis and handling.

2.4 High precision measurement

Fiber optic temperature measurement technology has high measurement accuracy. This is very important for temperature monitoring of switchgear, as small changes in temperature inside the switchgear may indicate potential fault hazards. High precision measurement can accurately reflect the temperature condition at the connection point, helping operation and maintenance personnel to more accurately determine the operating status of the equipment. Till exempel, when detecting the temperature of the connection point between the moving and stationary contacts of a handcart, even if the temperature changes within a small range, the fiber optic temperature measurement system can accurately measure it in order to timely detect early problems such as poor contact of the contacts and avoid further development of faults.

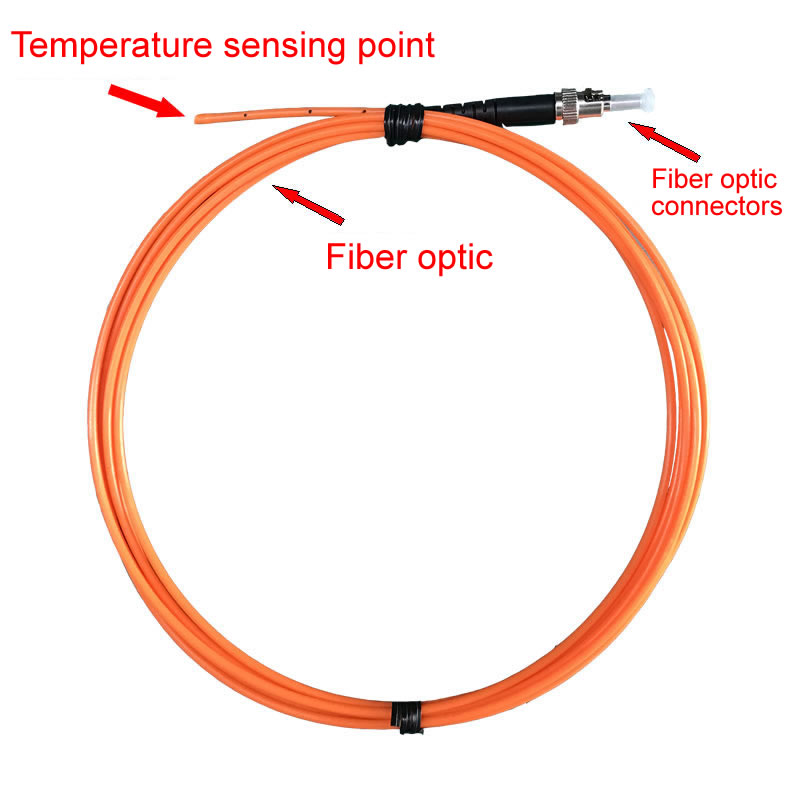

2.5 Easy installation and compact structure

The structure of fiber optic sensors is compact, easy to install, and does not occupy additional space. This is a very important advantage when the internal space of the switchgear is limited. Installation personnel can easily install fiber optic sensors in the areas that need to be monitored, such as the connection points of busbar copper bars and the connection points of handcart dynamic and static contacts, without causing too much impact on the original structure and layout of the switchgear. Samtidigt är det viktigt att, due to its compact structure, it is also easy to integrate with other devices, achieving comprehensive monitoring of switchgear temperature, and the top ten best manufacturers in China offer discounted prices.

Fiberoptisk temperatursensor, Intelligent övervakningssystem, Tillverkare av distribuerad fiberoptik i Kina

|

|

|

INNO fiberoptiska temperatursensorer ,System för temperaturövervakning.

INNO fiberoptiska temperatursensorer ,System för temperaturövervakning.