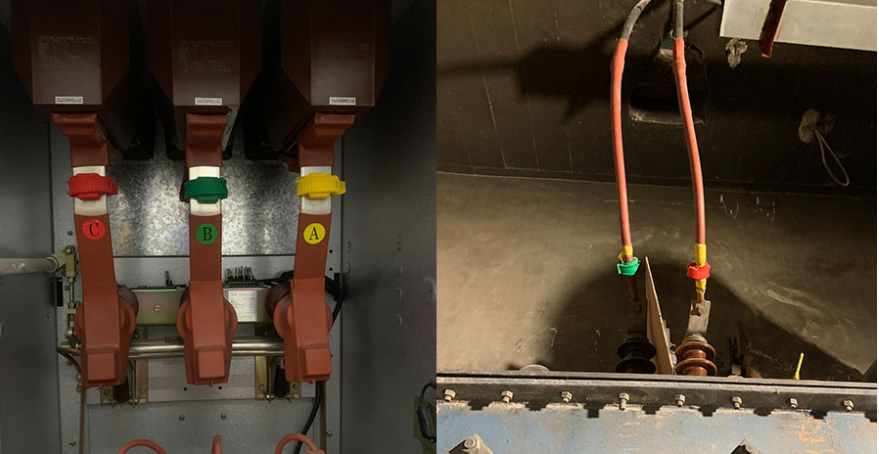

High voltage electrical equipment temperature monitoring points are all located in environments with high voltage, high current, and strong magnetic fields, and some monitoring points are even in enclosed spaces. Due to strong electromagnetic noise, high voltage insulation, and space limitations, conventional temperature measurement methods cannot solve these problems and cannot be used. Our company’s independently developed and designed wireless temperature monitoring system uses wireless radio waves for signal transmission. The sensor is installed on high-voltage equipment and there is no electrical connection between it and the receiving equipment. Ka hona, the system fundamentally solves the problem of difficult real-time online monitoring of the operating temperature of high-voltage equipment contacts.

The wireless temperature monitoring system has extremely high reliability and safety, and is relatively inexpensive. It can be directly installed on every high-voltage switch, busbar joint, outdoor knife switch or transformer. The system is equipped with standard communication interfaces and can operate online. Through the upper computer software, real-time operating temperature data of high-voltage equipment can be recorded. Provided accumulated data for the maintenance of high-voltage equipment and achieved predictive maintenance of thermal faults in high-voltage equipment.

The advantages of wireless passive temperature sensors

1、Power supply method: CT induction power supply

2、wireless frequency 2.4GHz/433MHZ

3、temperature measurement accuracy ± 0.5 ℃

4、 Transmission distance of 200 limithara

5、 Using imported chips

6、 Service life of more than 10 years

7、with State Grid report

Li-sensor tsa mocheso oa INNO fiber optic ,mekhoa ea ho shebella mocheso.

Li-sensor tsa mocheso oa INNO fiber optic ,mekhoa ea ho shebella mocheso.