Zašto visokonaponski razvodni uređaji trebaju merenje temperature

Sa razvojem elektroenergetske tehnologije, Visokonaponske i ultranaponske distributivne mreže sve se više pojavljuju u glavnim elektroenergetskim mrežama. Kao važna električna oprema, Visokonaponski razvodni uređaji mogu izazvati pregrevanje i ozbiljne požarne nesreće zbog starenja kontakata i povećanog otpora kontakta tokom dugotrajnog rada. Poslednjih godina, Došlo je do višestrukih incidenata pregrevanja razvodnih uređaja u elektranama i trafostanicama, što je dovelo do požara i rasprostranjenog nestanka struje. Rešavanje problema pregrevanja razvodne opreme je ključ za sprečavanje takvih nesreća. Sa brzim napretkom energetske tehnologije, Prenos i distributivni sistem se postepeno razvija ka tehnologiji, Bezbednost, i inteligencija. U praktičnoj upotrebi, Nepredvidive nesreće često nastaju zbog faktora kao što su profesionalni kvalitet instalacionog osoblja, neujednačen kvalitet kablovske opreme, i surovo okruženje.

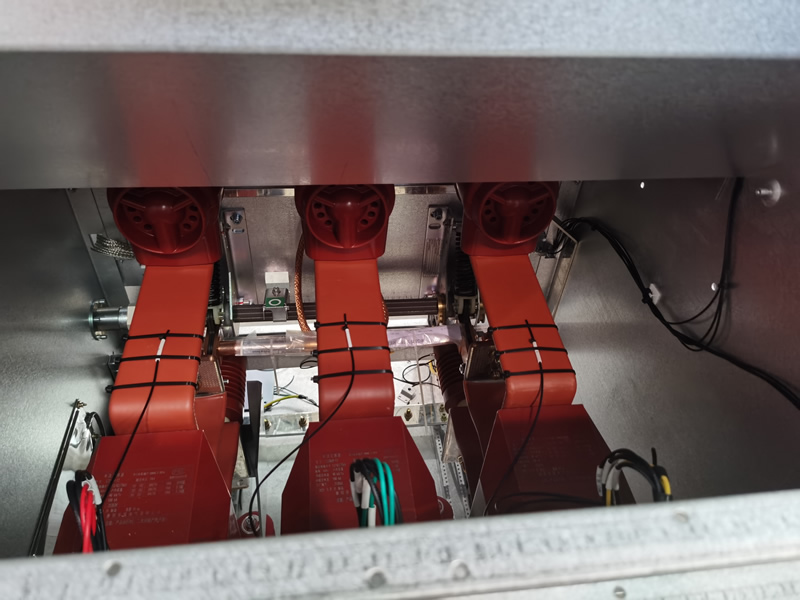

Zašto visokonaponska razvodna sabirnica meri temperaturu

U postrojenju za napajanje, Sabirnica je važna komponenta za prenos struje. Zbog svoje otpornosti, To će generisati toplotu prilikom prenošenja struje, posebno kada se prenose velike struje, to će generisati značajan porast temperature. Kada porast temperature sabirnice prelazi određenu vrednost, To može izazvati greške na razvodnoj opremi, i u težim slučajevima, takođe može izazvati požare, izaziva značajne gubitke u distributivnom sistemu. Neophodno je pratiti radnu temperaturu sabirnice rasklopne naprave kao odgovor na gore navedena pitanja.

Kontaktni delovi sabirnice u visokonaponskoj i niskonaponskoj razvodnoj opremi često stvaraju toplotu zbog starenja, labave zavrtnji, ili loš kontakt, što dovodi do prekomernog otpora kontakta. Ako se temperatura ovih grejnih delova ne može pratiti u realnom vremenu, lako je izazvati gori opremu ili iznenadne nestanke struje i druge nesreće. Sabirnica je važna komponenta veza kola, i struja teče kroz njega. Pre nesreće, abnormalna struja ili grejanje na mestu greške može izazvati povećanje temperature sabirnice. U ovom trenutku, ako postoji inteligentni sistem za merenje temperature koji može da meri temperaturu sabirnice, može da obezbedi rano upozorenje i spreči potencijalne probleme. Iako ručni pregled rada razvodnog uređaja može efikasno sprečiti nesreće izazvane njegovim grejanjem, postoji izložen visok napon unutar razvodne opreme i prostor je ograničen, onemogućavanje ručnog pregleda i merenja temperature. Trenutno, Nadgledanje kontaktne temperature unutar razvodne opreme može efikasno sprečiti nesreće. Međutim, zbog visokonaponske strukture unutar razvodne opreme, Ručni pregled i merenje temperature nisu efikasni. Nove sabirnice su opremljene zaštitnim poklopcima i koriste se infracrveni temperaturni pištolji, što onemogućava merenje temperature iz prozora za posmatranje. Uobičajene metode merenja temperature ne mogu se koristiti.

Online sistem za praćenje optičke temperature razvodne sabirnice

Korišćenje odgovarajućeg sistema za merenje temperature za merenje temperature sabirnice, posebno u tačkama 3 Ili 6 preklapanja, i sprovođenje online praćenja temperature sabirnice u realnom vremenu. Pre nego što dođe do nesreće, nenormalna struja ili grejanje na mestu greške može dovesti do porasta temperature sabirnice. Kroz optički inteligentni sistem za merenje temperature, temperatura sabirnice se može meriti, koji mogu da obezbede rano upozorenje i spreči potencijalne probleme. Merenje temperature fluorescentnih optičkih vlakana je veoma dobar plan implementacije. U Fluorescentna optička uređaj za merenje temperature uključuje fluorescentna optička senzor temperature sonda instalirana na sabirnici. Optički senzor temperature prenosi podatke o temperaturi osetio na transmiteru temperature, tako da osoblje može blagovremeno znati temperaturu na sabirnici preklapanja. Senzor temperature ima visoku tačnost merenja i može se široko promovisati i primenjivati u tehnologiji merenja temperature energetske opreme. Tačno čitanje i visoka pouzdanost. Optički senzor prolazi kroz posebnu obradu unutra, koji ne samo da ima dobru izolaciju, već i jaku otpornost na elektromagnetne smetnje, obezbeđivanje pouzdanosti i bezbednosti rada opreme bez ikakvih smetnji ili uticaja na energetsku opremu.

Optički senzor temperature, Inteligentni sistem praćenja, Distributed proizvođač optičkih vlakana u Kini

|

|

|

INNO optički senzori temperature ,sistemi za nadgledanje temperature.

INNO optički senzori temperature ,sistemi za nadgledanje temperature.