This article introduces the principle of fiber optic temperature sensors, the top 10 manufacturers of fiber optic temperature sensors in temperature measurement, and a list of the best fiber optic temperature sensor products.

The temperature measurement principle of fiber optic temperature sensors

The fluorescence temperature measurement device manufactured based on the functional relationship between fluorescence afterglow lifetime and temperature has advantages that traditional temperature measurement methods cannot compare with.

The basic principle of fluorescence temperature measurement

When a substance is excited, such as by short wavelength visible or ultraviolet light, electric field excitation, or chemical reactions, it will absorb and store energy, and transition to an excited state with a certain vibrational energy level through the ground state. But the excited state is not stable and may return to equilibrium, and when the external excitation source stops working, the luminescence phenomenon will continue for a period of time, which is called afterglow. U dodatku, during the deactivation process of fluorescent molecules, unstable excited state molecules will transition from high energy levels to low energy levels through energy level transitions, and the excess energy will emit light in the form of electromagnetic radiation. Zato, according to the different excitation methods, it can be divided into photoluminescence, electroluminescence, chemiluminescence, and bioluminescence.

According to Planck’s law, when the energy of the incident light is received by the luminescent material, it will excite electrons in the material to produce electron level transitions, and this process will produce outgoing light with a wavelength of λ. The formula for the energy difference between high and low energy levels is:

E2-E1=k λ v=kf

In the formula: E1- the energy of the electron at a lower energy level;

E2- Energy of electrons at higher energy levels;

K – Planck constant;

V – the propagation speed of light in vacuum;

F – frequency of light;

λ – The wavelength of the emitted light.

Due to E1 and E2 being in different energy bands, they represent light in a certain band, while the energy in the molecule includes rotational energy generated by electrons and vibrational energy caused by axial elastic vibrations between nuclei. Zato, when molecules absorb light radiation, after quantum transitions, the electron energy will rise from the ground state to a higher energy level, and the rotational energy and vibrational energy will change simultaneously, causing the three energies to interact with each other. After the incident light disappears, the luminescent material will continue to emit light for a period of time, and the emitted light is fluorescence; High frequency and short wave light energy will excite long wave and low frequency light, and follow Stokes’ law.

The basic theoretical basis of fluorescence measurement method is that when the intensity of the fluorescence linear spectrum shows monotonicity with temperature, and the temperature of the fluorescent substance determines the time of the light quenching process, fluorescence temperature measurement can be carried out. Zato, it is generally divided into fluorescence intensity temperature measurement method, fluorescence lifetime temperature measurement method, and laser induced fluorescence method. Među njima, the fluorescence lifetime temperature measurement method is not easily affected by the intensity of the excitation light source, coupling degree, and fiber transmission efficiency in the temperature measurement process, and has more obvious advantages in use. The temperature measurement principle is that after the excitation light source is removed, the time for the fluorescent substance to continuously emit fluorescence is called the fluorescence lifetime, which depends on the lifetime of the excited state. The fluorescence lifetime of fluorescent substances is related to the corresponding temperature within a certain temperature range. Fluorescence lifetime refers to the time it takes for the fluorescence intensity to decay to 1/e of its original intensity when the excitation light source is cut off, and its relationship with temperature can be expressed as:

τ (T)=1+e – Δ E/(KT) Rs+RTe – Δ E/(KT)

In the formula: Rs, RT, K, Δ E – constant;

T – thermodynamic temperature.

From this, it can be seen that the time constant of fluorescence afterglow decay is a single valued function of temperature and is only related to temperature.

Vrh 10 manufacturers of fiber optic temperature sensors

1、Fuzhou Inovacije Elektronski Scie&Tech Co., D.o.o..

The company has established over a hundred strategic partners and stands out in the power intelligent manufacturing industry, firmly at the forefront of the industry. Its main customers include well-known enterprises such as TBEA, Hainan Jinpan, Qianjiang Electric, Zhongdian Electric, Nanjing Daquan, and Ningbo AUX.

The product is widely used in fields such as power, Železnički tranzit, municipal comprehensive pipe gallery, nuclear power, new energy, Petrohemija, oil and gas pipelines, perimeter security, Itd. Through years of effort and accumulation, Inno has gained a good reputation in the field of intelligent monitoring, and the product is increasingly recognized by more and more customers.

In the future, Inno Technology will continue to unleash its scientific and technological innovation vitality, fully utilize the advantages and foundation of technology-based enterprises, and strive to become a leader in the field of fiber optic sensing!

MKS fiber optic temperature sensor probes are designed to offer industry leading accuracy, repeatability, and reliability for a wide range of applications. The probe is immune to RF and enables customers to monitor temperature in extreme environments. They are easy to install, robust and can be customized for OEM applications. Customized design available upon request.

- Immune to RF

- Highly accurate across full temperature range

- Excellent sensor-to-sensor precision

- Outstanding long-term repeatability

- Sensors do not require recalibration

- Probes and converters are fully interchangeable

At MKS, we have a long history of leveraging our collective curiosity to understand and develop solutions that are at the core of many key technological innovations. These innovations have driven accelerated roadmaps for Semiconductor, Industrial, Life and Health Sciences, Research and Defense markets.

3、Luna Innovations

Luna Innovations is proud of our rich tradition of working in close collaboration with customers to develop the products that meet and exceed our clients’ needs for sensing, test & measurement, monitoring, and control solutions. This heritage stems from a series of in-house technology innovations and acquisitions.

Fiber optic temperature sensors are immune to the many environmental effects that compromise other measurement technologies, can be embedded and installed in locations traditional temperature sensors cannot and deliver an unprecedented level of spatial detail and data without sacrificing precision and sensitivity.

4、Opsens Solutions

Opsens Solutions’ fiber optic temperature sensors provide second to none performance to various industries.

Our applications include monitoring in Nuclear Magnetic Resonance imaging (NMR) and Radio Frequency (RF) energy environments.

These sensors are perfectly tailored for energy related applications with high voltage and Electromagnetic disturbances (EMI). They can also survive radiated environment and are immune to microwave energy.

These sensors may be used in broad range of applications: from cryogenic environment (such as superconducting magnet), to high temperature applications up to 350 Celsius.

5、Omega Engineering, Inc.

6、Yokogawa

Yokogawa Electric Corporation announces that it will release the DTSX®3000 distributed temperature sensor on August 12. With a one meter spatial resolution, this distributed temperature sensor can measure the temperature along fiber-optic cables up to 50 km in length, eight times the distance possible with our previous model. In terms of measurement distance and temperature resolution, this is one of the industry’s top-performing distributed temperature sensors.

The DTSX3000 is well suited for plant and infrastructure maintenance applications that necessitate the monitoring of temperature over long distances or across wide areas. Specific applications include the detection of gas and liquid leaks in tanks and other large production facilities, and the detection of abnormal heat levels in power lines.

7、FISO Fiber Optic Temperature Sensors

FISO’s Fiber Optic Temperature Sensors provide accurate, stable, and repeatable measurements. These measurements are based on variations of the reflected light — when compared to the emitted light — due to thermal expansion of the highly stable glass used within the sensor. The fiber optic lead cable can be up to several meters long without affecting the quality or the accuracy of the results.

8、Althen Sensors and Controls

Fiber optic temperature sensors

Fiber optic temperature sensors use the properties of optical fibers to measure changes in temperature. These sensors offer several advantages over traditional electronic temperature sensors and are often used in environments with high temperatures, electromagnetic interference (EMI) or explosion hazards.

9、 Qualitrol

QUALITROL manufactures monitoring and protection devices for high value electrical assets and OEM manufacturing companies. Established in 1945, QUALITROL produces thousands of different types of products on demand, customized to meet unique requirements.

The Neoptix product line includes fiber optic temperature sensors for transformer windings temperature monitoring and for laboratory, industrial, and medical applications.

10、Advanced Energy

Advanced Energy offers highly reliable and precise fiber optic sensors for temperature measurement and sensing applications. The Luxtron® patented FluorOptic® technology allows for accurate temperature sensing in harsh environments where conventional sensors would fail, such as in semiconductor manufacturing, power electronics, and aerospace industries. With a variety of options to meet different application needs, these fiber optic sensors provide an ideal solution for monitoring temperature and ensuring process efficiency and product quality. Additionally, Advanced Energy’s WaveCaptureTM Fiber Bragg Grating (FBG) sensing solutions offer a reliable and cost-effective way to monitor strain and temperature in structures and materials. With the ability to measure strain with high accuracy, these FBG sensors are used in a variety of applications including aerospace, civil engineering, and oil and gas industries.

Ranking of the Best Fiber Optic Temperature Sensor Products

1、Fluorescentni optički senzor temperature sonde

Fluorescentna optička temperaturna sonda ima dobru električnu izolaciju, anti-elektromagnetne smetnje, hemijska otpornost na koroziju, nema zagađenja i mnogi drugi tradicionalni senzori temperature ne mogu se porediti sa prednostima.

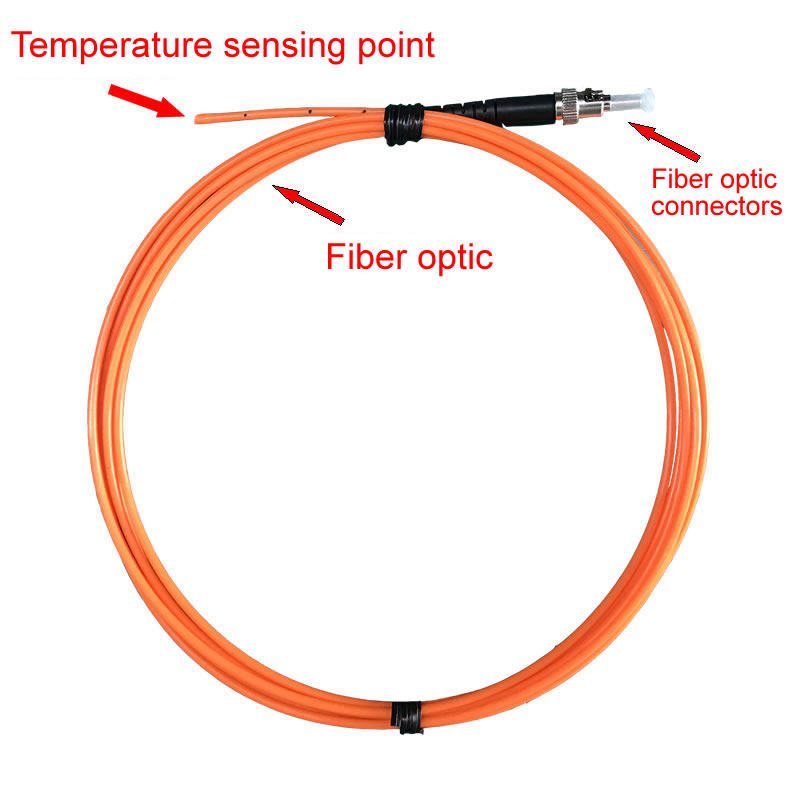

2、Distributed temperature measurement optical fiber armored temperature sensing optical cable

Fiber optic temperature sensing, FOTS is a temperature measurement technology based on optical fiber transmission signals, which utilizes the physical properties of optical fibers to achieve the transmission and measurement of temperature signals. The temperature sensing fiber optic sensor consists of a fiber optic transmission module and a temperature sensing head, which can measure temperature at any position and in any environment.

3、Fiber Bragg rešetka Senzor temperature

The IF-FBG fiber optic grating temperature sensor is a new type of temperature sensor developed specifically for temperature measurement of power switchgear, utilizing the inherent temperature sensing characteristics of fiber optic gratings. It is suitable for temperature monitoring and fire alarm at high-voltage power switchgear, high-voltage cable joints, Itd. in power plants, trafostanice, and other places. It has many advantages such as high temperature measurement accuracy, otpornost na visoki napon, anti creep, otpornost na koroziju, strong lightning resistance, and no strong electromagnetic interference.

Optički senzor temperature, Inteligentni sistem praćenja, Distributed proizvođač optičkih vlakana u Kini

|

|

|

INNO optički senzori temperature ,sistemi za nadgledanje temperature.

INNO optički senzori temperature ,sistemi za nadgledanje temperature.