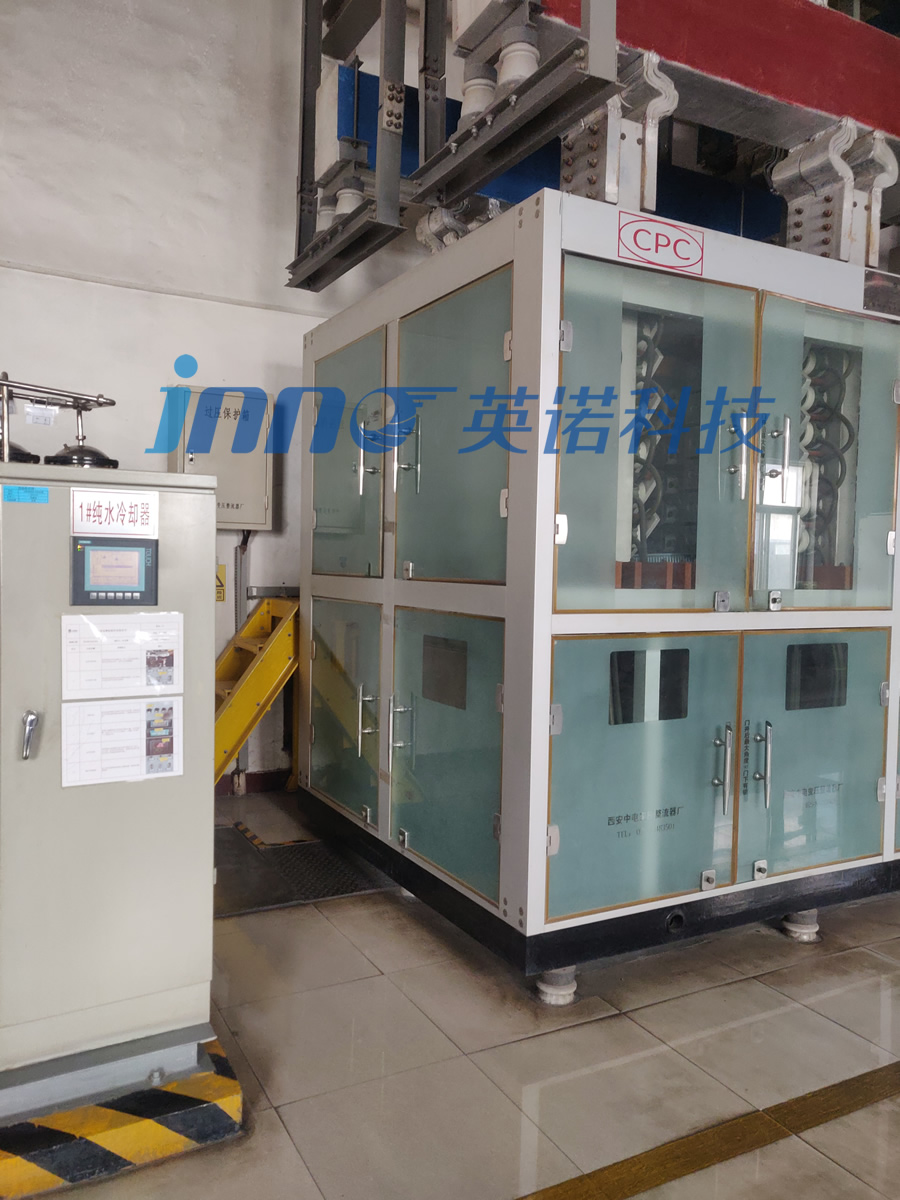

Function of fiber optic temperature measurement system for rectifier cabinet

1. The on-site temperature measurement device collects real-time temperature information of the switchgear contacts, Cabluri, and voltage transformer coils. The use of fluorescent fiber optic temperature probes has extremely strong electromagnetic immunity, voltage resistance, and insulation performance. Sensitive temperature sensing, stable and reliable long-term operation. The temperature measurement accuracy can reach ± 1 °C.

2. The system comes with sound and light alarms, dry contact output, and human-machine interface display of alarm information.

3. The backend monitoring software system displays real-time temperature information of each contact point in the current switchgear, real-time curves, and historical data storing temperature information of each contact point in the past month.

Using various diagnostic methods to analyze the health status of equipment, including analysis of all equipment parameter out of limit alarms and other judgment methods, to timely monitor the operation status of high-voltage switchgear. The system can automatically and manually generate various periodic reports, which can be exported and printed. The exported reports can be edited and viewed through Excel software. În același timp, the system has real-time and historical temperature curve display functions, which can accurately reflect the real-time monitoring curve and the temperature change curve of the monitored object at a certain point during a certain period of time;

4. Detect temperature abnormality alarm

Over threshold alarm: When the temperature value is detected to exceed the threshold, an alarm can be triggered, and two levels of thresholds can be set;

Exceeding temperature difference alarm: If the temperature difference between the highest and lowest temperatures within a certain range of test points exceeds the set value (threshold can be set), the alarm will be triggered;

Temperature difference change rate alarm: If the temperature change exceeds the set value (threshold 19 can be set) within a certain period of time, the alarm will be triggered;

sistem fault alarm: The system monitors the performance status of the fiber optic temperature measurement probe and the connection status of the fiber optic, realizes self diagnosis and testing, and promptly prompts system faults;

5. Detect temperature anomalies, system failures, etc., and the system will automatically alarm to achieve unmanned monitoring.

Senzor de temperatură cu fibră optică, Sistem inteligent de monitorizare, Producător de fibră optică distribuită în China

|

|

|

Senzori de temperatură cu fibră optică INNO ,Sisteme de monitorizare a temperaturii.

Senzori de temperatură cu fibră optică INNO ,Sisteme de monitorizare a temperaturii.