Partial discharge is a type of pulsed discharge that generates a series of phenomena and chemical changes such as light, sound, electrical, and mechanical vibrations inside and around power equipment. These physical and chemical changes that accompany partial discharge can provide detection signals for monitoring the internal insulation status of power equipment. Multi in one integrated state wireless sensors achieve intelligent perception of the operating status of power equipment through the integration of transient voltage, ultrasound, ultra-high frequency, temperature, humidity, and ozone; Through intelligent diagnostic algorithms and multi-dimensional comparative analysis, intelligent analysis of monitoring data and intelligent diagnosis of equipment status can be achieved. Real time monitoring of operating status can be achieved, defects and problems can be detected in a timely manner, abnormal information can be evaluated and pushed, and maintenance strategy suggestions can be provided. This provides data support for operation and maintenance personnel to formulate maintenance strategies, effectively avoiding sudden power outages, fires, and personal and equipment injury incidents.

The ultra-high frequency method for partial discharge detection in switchgear is a new type of method. Due to the high signal frequency received by ultra-high frequency sensors, they are less affected by external interference and can greatly improve the sensitivity and reliability of partial discharge detection in switchgear.

The high-voltage cable partial discharge online monitoring system is a new generation of high-performance digital partial discharge online monitoring device implemented using the latest sensor technology, signal processor, computer technology and algorithms. The use of partial discharge sensors and partial discharge monitoring devices in this system has been tested for long-term operation in multiple substations and power plants (both indoor and outdoor), and has been reliable and stable. Some products have also been found to have discharge faults in the monitored equipment on site, avoiding the occurrence of major accidents. Practical applications have proven that the products provided by this system can fully adapt to the requirements of the on-site environment.

The ultra-high frequency sensor relies on magnetic adsorption on the indoor wall of the switchgear cable, and the installation process is simple and fast. The lead out of the ultra-high frequency sensor needs to pass through the interlayer below the switchgear and lead out to the cable trench or cable room below the switchgear. The online monitoring device for partial discharge in the switchgear is suspended on the wall of the cable trench (cable layer).

The online monitoring system for partial discharge in transformers is designed specifically for monitoring the insulation status of transformer equipment. It flexibly uses various technologies such as ultra-high frequency (UHF), high-frequency current (HFCT), ultrasound (AE), etc. to monitor the partial discharge signals inside the transformer in real time. Through data analysis software and intelligent diagnostic systems in the background, the partial discharge signals are analyzed and processed to evaluate the insulation status of the transformer, determine the type and approximate location of defects, and provide maintenance suggestions.

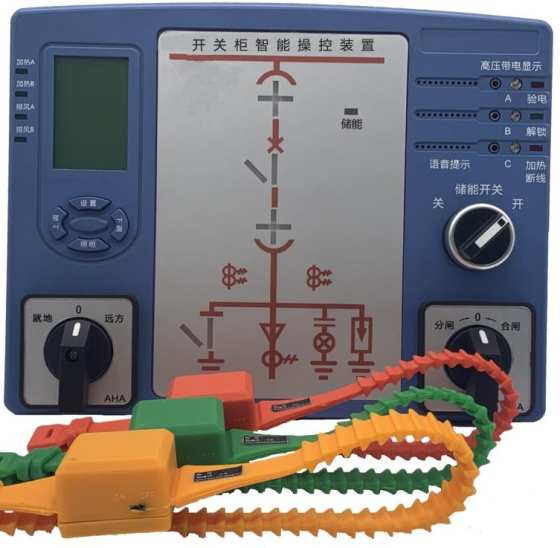

The three in one sensor intelligent data acquisition unit is a type used for high, medium, and low voltage power switchgear. This device needs to be used in conjunction with intelligent sensors (three in one) for partial discharge monitoring in switchgear. It is a multifunctional partial discharge detection product that integrates online ultra-high frequency, ground wave/ultrasonic/ultra-high frequency, data acquisition, and data analysis. This device provides a communication interface that can be connected to a computer monitoring system, supports RS485 interface MODBUS-RTU communication protocol, and has a communication baud rate of 9600. The intelligent sensor for partial discharge monitoring in the switchgear (three in one) adopts high-performance battery power supply, adsorption installation, wireless communication and other methods for easy on-site installation. In addition, it adopts various anti-interference measures in design and can operate stably in the power system.

Main functions:

1. Timing data collection based on the principles of ground waves, ultrasonic waves, and ultra-high frequencies. It is recommended to use the same collector for data collection in the three in one distribution room

2. Upload the average and peak values of TEV/AE/UHF partial discharge collection.

3. Upload data such as mean, peak, alarm level, and graph to the online collection unit,

4. Equipped with device parameter configuration function, capable of programming and setting main parameters,

5. Equipped with RS485 communication interface, Ethernet interface can be customized for special applications.

Data communication function, all data can be uploaded to the upper level collector or uploaded to the upper computer system through the data communication bus.

INNO fibre optic temperature sensors ,temperature monitoring systems.

INNO fibre optic temperature sensors ,temperature monitoring systems.