Product Features

2、Immune to electromagnetic and microwave interference

3、Withstand high voltage

4、’No calibration required

5、Measures hot spot temperatures with direct contact

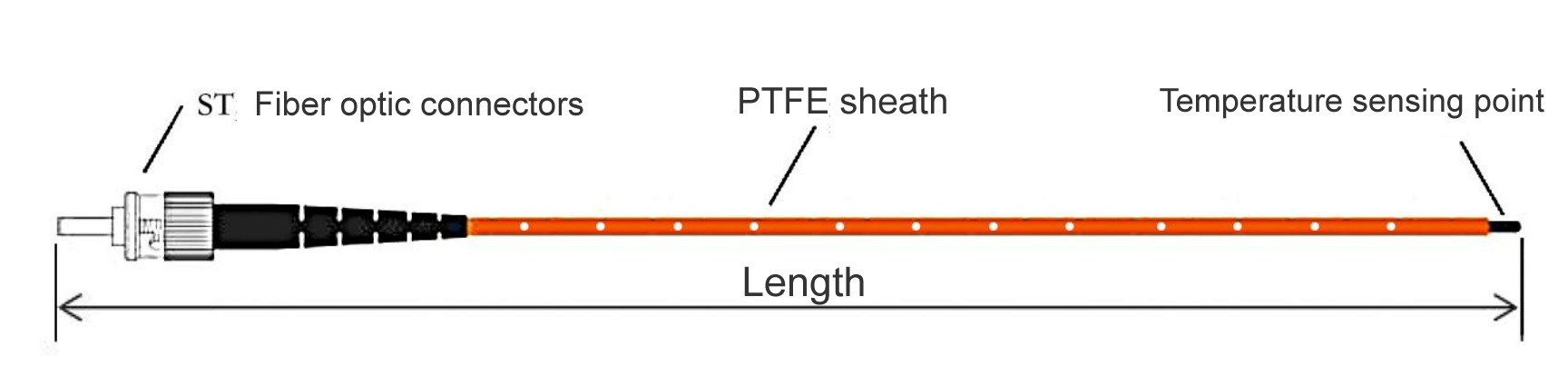

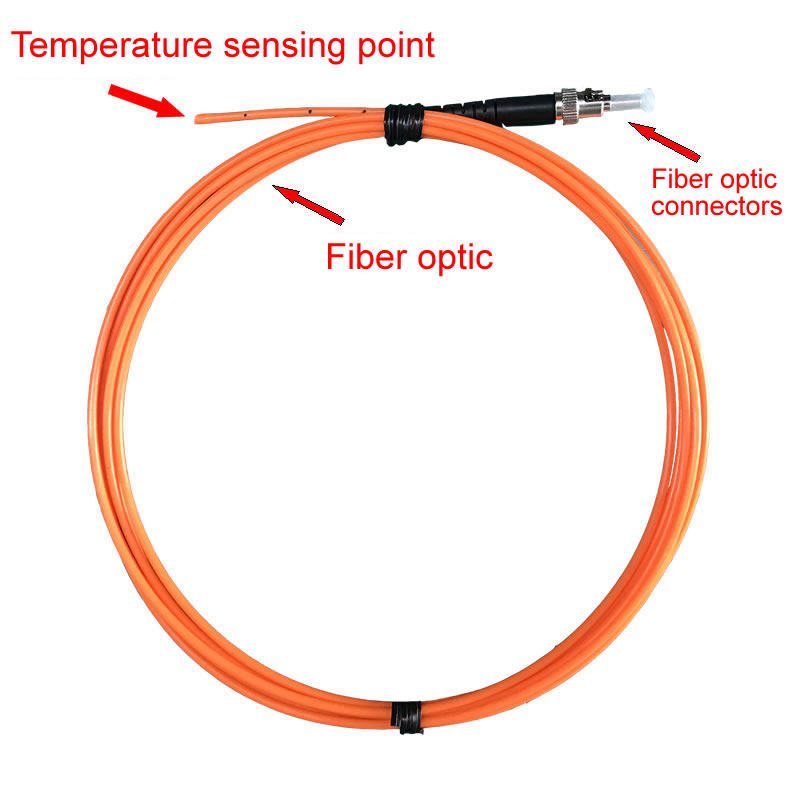

Fluorescent fiber optic temperature sensor probe will monitor the part of the temperature information is converted into light signals and transmitted to the fiber optic temperature transmitter, fiber optic sensor probe can be installed directly on the measured point, accurate temperature measurement, rapid response: its pigtail selection of soft, strong, specially designed optical fiber, with anti-electromagnetic interference, bending resistance, impact resistance and high strength; fiber optic sheath using PTFE, high temperature, aging resistance, corrosion-resistant, with high temperature resistance, aging resistance, corrosion resistance, high insulation, non-adhesion and other characteristics, can be adapted to high pressure, high temperature, strong electromagnetic and other harsh environments. Not only in the electric power industry, such as: high-voltage electrical equipment instrumentation temperature measurement, generator diagnostic system and transformer winding temperature measurement, high-voltage circuit breaker contact temperature measurement, cable joint temperature measurement, etc., widely used, but also in biology, medicine and other areas that require high-precision temperature measurement should also be suitable.

Introduction of fluorescent fiber optic sensing probe

The scope of application includes but is not limited to

Measurement of hotspots in high-voltage power switchgear, including copper busbars, moving contacts, static contacts, incoming and outgoing lines, etc;

Temperature monitoring of GIS cabinets, medium voltage cabinets, and low-voltage cabinet drawer cabinets;

Cable joints for ring main cabinets and temperature monitoring for box type substations;

Hot spot monitoring of dry-type transformer coils and oil immersed transformer windings;

Measurement of stator pressure index and collector ring temperature for water turbines/thermal/wind turbines;

Temperature measurement of enclosed busbars and cables;

Temperature monitoring in oil;

IGBT or chip surface temperature measurement;

Temperature measurement of fan blades; Temperature measurement at the connector connection point;

Medical hyperthermia human contact temperature measurement;

Nuclear magnetic resonance, ERFI, EMI, NMR, RF, microwave;

Etching machines, deposition equipment, small gaps, chemical liquids, vacuum environments;

Ring network cabinet head, hot spot temperature online monitoring;

Temperature monitoring for other harsh special environments.

INNO fibre optic temperature sensors ,temperature monitoring systems.

INNO fibre optic temperature sensors ,temperature monitoring systems.