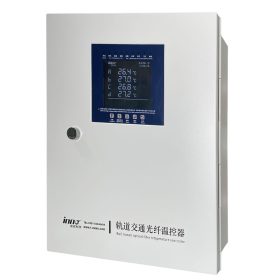

The fiber optic temperature controller for rail transit is a type of temperature controller specially designed for special fields such as subways, locomotives, aviation, etc; Due to the impact current interference of traction current on track circuits in these fields, as well as the interference of unbalanced current and poor traction return current, temperature controllers are required to have good electromagnetic compatibility in these aspects.

Our independently developed fluorescent fiber optic temperature sensor is a new principle temperature measurement device. Its principle is that the fiber optic module emits laser, which is transmitted to the end of the temperature sensing probe through the fiber optic. The rare earth material at the end receives light, and the reflected light is transmitted back to the fiber optic module. The fiber optic module decomposes the temperature information in the reflected light.

This product uses our company’s independently developed fluorescent fiber optic temperature sensor as the temperature sensing element. This temperature sensing element is immune to electromagnetic interference and resistant to high voltage (100KV/fiber to ground lead distance of 0.4m). Fluorescent fiber optic temperature measurement completely cuts off the interference transmitted from the temperature measuring element to the temperature controller from the temperature measurement source. The overall anti-interference ability of the temperature controller is extremely strong, the output contact capacity is large, the functions are complete, the LCD interface is illustrated, the setting is simple, and easy to operate, with reliable EMC and EMI performance.

| basic function | 1. Provide three-way winding temperature measurement; Automatic/manual start stop cooling fan function; Digital compensation function for display values of each channel; LCD display, LED display light, with operation keyboard; Provide clock function; |

| 2. Provide black box function, which can record temperature data before power failure and historical maximum temperature; | |

| 3. Provide transformer door cabinet point opening alarm function: | |

| 4. Provide one set of over temperature alarm contacts (one normally open and one normally closed); | |

| 5. Provide two sets of over temperature trip contacts (two normally open and two normally closed); | |

| 6. Provide one set of iron core alarm contacts (one normally open and one normally closed); | |

| 7. Provide one set of remote transmission contacts for the fan (one normally open and one normally closed); | |

| 8. Provide one set of temperature controller power-off alarm contacts (one normally open and one normally closed); | |

| 9. Provide one set of temperature controller fault alarm contacts (one normally open and one normally closed); | |

| 10. Fan fault diagnosis function, and provide a set of fan fault alarm contacts (L function); | |

| 11. Iron core temperature measurement function, and provide a set of iron core over temperature alarm contacts (I function): | |

| 12. Provide RS485 communication function, communication with time markers, and can receive time synchronization (F function: standard MODBUS-RTU protocol); | |

| Additional features (customizable) | 1. Provide 4-8 channels of 4-20mA analog current output function (E function) |

| 2. Local or remote confirmation and reset function for fault information: | |

| 3. The communication protocol can use methods such as Profibus, IEC60870-5-103, Ethernet communication, etc; |

Standard of Execution:

| Production standards | JB/T7631-2005″Electronic temperature controller for Transformers”Industry standards |

| Adoption of accreditation standards: | ISO9001:2008International Quality Management System Certification |

| Pass the test standard: | IEC61000-4:1995 International standard |

| GB/T17626-2008″Electromagnetic compatibility test and measurement techniques”standard |

Characteristics of temperature controllers for rail transit:

1. The protection level is IP54.

2. The output contact capacity is large.

3. Fiber optic temperature measurement is the first in China and at the international leading level.

4. The temperature controller uses the ARM architecture CPU, which has strong data processing capabilities and stable system performance.

5. Large LCD screen with digital and Chinese display.

The design concept of the circuit board for button operation and LED signal indication display of the temperature controller is modular design, with strong and weak electrical separation to avoid spatial crosstalk.

7. The temperature controller contains a clock chip and an external FLASH, which can be customized for high-capacity, time marked historical data storage

INNO fibre optic temperature sensors ,temperature monitoring systems.

INNO fibre optic temperature sensors ,temperature monitoring systems.

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.