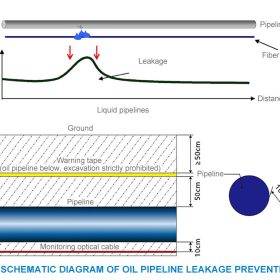

The distributed fiber optic temperature online monitoring system is currently an advanced technology for non electric monitoring of oil pipelines. It conducts online distributed temperature monitoring of oil pipelines and is connected in parallel by various oil pipeline monitoring equipment to the local area network of the comprehensive online monitoring system of oil pipelines. The alarm data and temperature information are uploaded to the central server through network signals.

In the early stage of oil pipeline damage and leakage, it is possible to determine, detect and report the specific location, temperature changes, and other information data of oil pipeline leakage warning points in the first time, providing reliable and solid information acquisition means for the use and management departments of oil pipelines to timely locate and analyze possible infringement events and line damage, and providing efficient safety guarantees for the safe operation of the oil pipeline system.

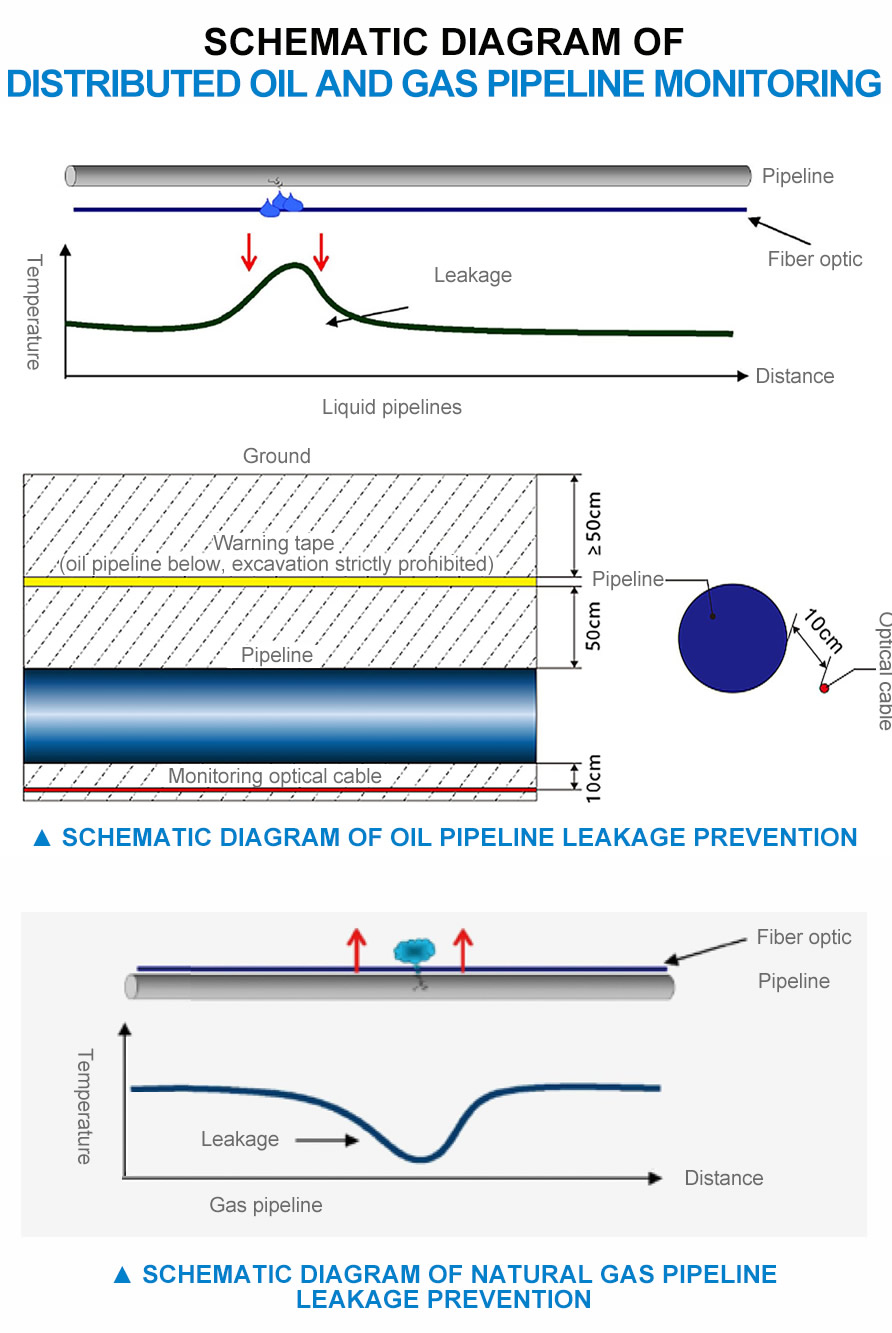

The natural gas in natural gas pipelines is highly compressed. When a leak occurs, the natural gas inside the pipeline erupts from the rupture and then rapidly expands. During this process, natural gas will absorb a large amount of surrounding heat, leading to a sharp drop in temperature near the rupture site.

The distributed fiber optic pipeline leakage monitoring system has the following technical advantages:

Fastness

The system has a very high temperature measurement and positioning speed. In order to improve measurement time, the advantage of high-speed weak signal processing technology is adopted, with a minimum single measurement time of 1 second and fast response speed.

Distribution characteristics

The distributed fiber optic pipeline leakage monitoring system can provide continuous dynamic monitoring of temperature changes at points every 0.5 meters within a range of more than ten kilometers, and can set temperature alarm values at any level.

Progressiveness

The distributed fiber optic pipeline leakage monitoring system is currently the most advanced distributed temperature measurement product with the highest performance indicators, strongest functionality, highest reliability, and most advanced technology in the world. High performance components are selected for key components, and the core algorithm has been rigorously tested.

accuracy

The temperature resolution of the system reaches 0.5 ℃, with a temperature accuracy of 1 ℃ and a spatial resolution of 0.5m.

flexibility

The system adopts real-time online monitoring mode; The time for uploading alarm signals from any point within the monitoring range to the fire alarm controller shall not exceed 30 seconds.

The monitoring system provides a continuous dynamic monitoring signal, and the system can set multi-level temperature point alarms. The system supports multi-level alarms, such as initial alarm at 30 ℃, early alarm at 40 ℃, and measures taken at 50 ℃. The temperature parameters of the alarm points can be set according to different environments; There are multiple alarm methods with differential temperature control, and the alarm parameters can be set in zones according to customer needs, with flexible alarm methods.

compatibility

The system host adopts an open communication protocol and provides a communication interface to connect with the workstation. The disaster prevention alarm workstation in the central control room displays all information such as temperature curve, alarm position, and alarm temperature in Chinese graphic and textual format.

The system can be connected to other control devices such as PC and fire alarm systems through output forms such as RS232, RS485, built-in relays, RJ45, or other industrial protocols, to perform sound and light alarms, and the signal output is accurate and complete.

Security

The distributed fiber optic pipeline leakage monitoring system has a safety record function, which can store historical data within one year and can be effectively audited.

Single end operation, remote diagnosis, and the lowest level of system remote diagnosis can be provided by specialized engineers through the local area network; If the optical fiber is damaged, the DTS system can immediately locate the damaged point and fuse it through the fiber fusion splicer without stopping the measurement, which is very important for effective online monitoring.

The intrinsic safety of the detection optical cable is achieved by using optical signals, which will not cause mutual electromagnetic interference with the power cable.

User software

Provide a user-friendly and easy-to-use distributed fiber optic temperature monitoring application software. The software mainly includes functional modules such as temperature monitoring, fire alarm, and visual display.

Temperature curve display

The system can display the real-time temperature distribution curve of the entire optical cable, and when there is an abnormal temperature at a certain location, the curve can show whether the temperature at that location increases or decreases.

Distributed Fiber Optic Long Oil and Gas Pipeline Safety Monitoring System

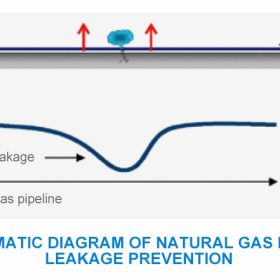

Long distance oil and gas pipelines are mostly distributed in deserted areas such as the wilderness, and are susceptible to external human damage and sudden natural disasters (such as earthquakes, landslides, etc.), resulting in pipeline rupture and oil and gas leakage accidents. Due to the characteristics of high temperature, high pressure, flammability, and explosiveness of oil and gas pipelines, once a leak occurs, it not only shuts down the pipeline, but also seriously pollutes the environment, posing a serious threat to the lives and property of local people. If it causes the combustion and explosion of leaked oil and gas, the consequences are even more unimaginable.

Fiber optic sensing technology, with its ability to achieve long-distance passive distributed sensing, is very suitable for the safety monitoring market demand of long oil and gas pipelines. Its on-site non electric detection, wide coverage range, and high positioning accuracy are currently recognized as the best technical solution.

Our company has launched a distributed fiber optic oil and gas pipeline safety warning system to meet the demand for safety monitoring and early warning applications in long-distance oil and gas pipelines, providing a solution to ensure the safe operation of oil and gas pipelines. Multi parameter comprehensive perception of potential risks along the pipeline, using deep learning algorithms to analyze and identify threat events along the pipeline, making the safe operation management of oil and gas pipelines more intelligent, orderly, real-time, and efficient.

INNO fibre optic temperature sensors ,temperature monitoring systems.

INNO fibre optic temperature sensors ,temperature monitoring systems.