China’s chemical storage tanks mainly use floating roof tanks and spherical tanks. The top of the floating roof oil tank adopts secondary sealing technology, but it is not completely sealed, and there is a possibility of a small amount of chemical liquid and gas leaking out of the sealing ring. These leaked gases are prone to fire under natural conditions such as high temperature in the sun and lightning strikes. The detection of fires is particularly important. Due to the outdoor location, large volume, and wide tank area of storage tanks, linear fire detectors are commonly used.

Advantages of Distributed Fiber Optic Temperature Measurement System for Oil Storage Tanks

(1) Sensors and optical cables not only serve as temperature detectors but also play an important role in signal transmission, integrating transmission and sensing. As there is no need to install additional sensing components, there is no fusion point in the middle of the sensing optical cable, resulting in high reliability.

(2) Continuous distributed measurement without measurement blind spots: DTS belongs to continuous distributed measurement and can obtain the temperature of each point along the sensing optical cable. Currently, the distance interval between adjacent temperature points can reach up to 0.25m, with rich temperature information and no measurement self zone. Moreover, based on continuous temperature analysis, regional temperature difference alarm can be achieved.

(3) Low workload for later operation and maintenance: DTS’s sensing optical cables are designed based on outdoor communication optical cables, and the service life of communication optical cables can reach up to 30 years; The core components of the DIS measurement host, such as light sources and splitters, are all communication grade devices with a designed lifespan of 100000 hours (more than 10 years). The host is equipped with a temperature calibration unit and a fault self check module, ensuring stable and reliable temperature measurement.

Software functions of distributed fiber optic temperature measurement system for oil storage tanks

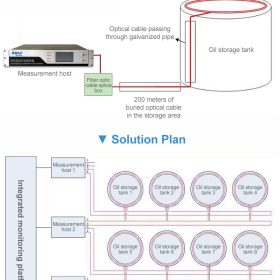

Based on the distribution characteristics of oil tanks and specific requirements for temperature monitoring, a “one tank, one machine” mode is adopted for design. At the same time, to increase system stability, dual machine hot standby is adopted, which can automatically switch in case of system failure. The fiber optic distributed temperature monitoring system monitors the required oil tanks in real-time online.

1) Each tank is monitored by an independent sensing optical fiber, which is installed on the floating plate of the tank and at the outer edge of the secondary sealing ring.

2) The anti-static optical fiber led out by the fiber optic temperature sensor installed on the floating plate inside the tank is protected by laying an explosion-proof metal hose inside the tank. The upper end of the explosion-proof metal hose is fixed on the flange plate of the manhole on the tank top, and the lower end of the metal hose is fixed on the floating plate inside the tank. The fixing method is non hot work, and the explosion-proof metal hose is equipotentially connected to the tank body.

3) Considering the changes in displacement at the top of the floating roof tank, in order to prevent the anti-static optical fiber passing through explosion-proof metal hoses from malfunctioning due to dragging, the reserved length should not be less than 0.5 times the height of the outer wall of the tank, and a disc optical fiber device should be used to control the anti-static optical fiber in a certain position area.

4) The anti-static optical fiber led out by the fiber optic temperature sensor installed on the floating plate inside the tank is laid with explosion-proof galvanized pipes outside the tank and led along the escalator or tank wall to the existing cable tray on the ground. It is connected and protected with the communication optical cable installed inside the cable tray through a waterproof optical cable splice box, and the elbow part is connected with explosion-proof metal hoses.

5) All fiber optic temperature sensors installed on the floating roof of each oil tank in the tank area are led out through anti-static optical fibers and converged to communication optical cables for signal collection and transmission to the monitoring room. The communication optical cable is laid directly buried, and the elbow is connected with explosion-proof metal hose.

6) After the communication optical cable is transmitted from the tank area to the monitoring room, it is connected to the detection channel interface corresponding to the DTS host through a short distance fiber optic tail with a standard fiber optic connector, which is a fiber optic jumper.

7) A multi-channel DTS distributed fiber optic temperature measurement host is placed in the monitoring room to achieve temperature signal acquisition, temperature rise warning, over temperature alarm, fault detection, and information management operations for the fiber optic temperature sensors installed on the oil tank site. It can be connected to the fire alarm control system through the switch alarm interface to achieve fire alarm and display it in the fire duty room. The current temperature value, alarm status, and historical temperature curve of all temperature sensing points of the storage tank can be visually displayed in the instrument operation room through the electronic map of the configuration software. An external sound and light alarm can also be connected to the instrument operation room to provide alarm signals.

INNO fibre optic temperature sensors ,temperature monitoring systems.

INNO fibre optic temperature sensors ,temperature monitoring systems.