China’s chemical storage tanks mainly use floating roof tanks and spherical tanks. The top of the floating roof oil tank adopts secondary sealing technology, but it is not completely sealed, and there is a possibility of a small amount of chemical liquid and gas leaking out of the sealing ring. These leaked gases are prone to fire under natural conditions such as high temperature in the sun and lightning strikes. The detection of fires is particularly important. Due to the outdoor location, large volume, and wide tank area of storage tanks, linear fire detectors are commonly used.

Advantages of Gentian Optik Teragih Temperature Measurement System for Oil Storage Tanks

(1) Sensors and optical cables not only serve as temperature detectors but also play an important role in signal transmission, integrating transmission and sensing. As there is no need to install additional sensing components, there is no fusion point in the middle of the sensing optical cable, resulting in high reliability.

(2) Continuous distributed measurement without measurement blind spots: DTS belongs to continuous distributed measurement and can obtain the temperature of each point along the sensing optical cable. Kini, the distance interval between adjacent temperature points can reach up to 0.25m, with rich temperature information and no measurement self zone. Selain itu, based on continuous temperature analysis, regional temperature difference alarm can be achieved.

(3) Low workload for later operation and maintenance: DTS’s sensing optical cables are designed based on outdoor communication optical cables, and the service life of communication optical cables can reach up to 30 Tahun; The core components of the DIS measurement host, such as light sources and splitters, are all communication grade devices with a designed lifespan of 100000 Jam (more than 10 Tahun). The host is equipped with a temperature calibration unit and a fault self check module, ensuring stable and reliable temperature measurement.

Software functions of distributed fiber optic temperature measurement system for oil storage tanks

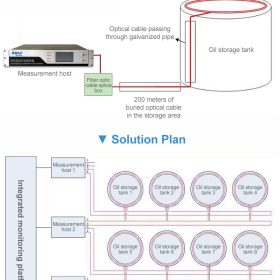

Berdasarkan ciri-ciri pengedaran tangki minyak dan keperluan khusus untuk pemantauan suhu, a “satu kereta kebal, satu mesin” mode is adopted for design. Pada masa yang sama, untuk meningkatkan kestabilan sistem, Siap sedia panas mesin dwi diguna pakai, yang boleh bertukar secara automatik sekiranya berlaku kegagalan sistem. The fiber optic distributed temperature monitoring system monitors the required oil tanks in real-time online.

1) Setiap tangki dipantau oleh gentian optik penderiaan bebas, yang dipasang pada plat terapung tangki dan di pinggir luar cincin pengedap sekunder.

2) The anti-static optical fiber led out by the Sensor suhu gentian optik installed on the floating plate inside the tank is protected by laying an explosion-proof metal hose inside the tank. The upper end of the explosion-proof metal hose is fixed on the flange plate of the manhole on the tank top, dan hujung bawah hos logam dipasang pada plat terapung di dalam tangki. Kaedah penetapan adalah kerja yang tidak panas, dan hos logam kalis letupan disambungkan ke badan tangki.

3) Memandangkan perubahan dalam anjakan di bahagian atas tangki bumbung terapung, untuk mengelakkan gentian optik anti-statik melalui hos logam kalis letupan daripada tidak berfungsi akibat menyeret, Panjang yang dikhaskan tidak boleh kurang daripada 0.5 kali ketinggian dinding luar tangki, dan peranti gentian optik cakera hendaklah digunakan untuk mengawal gentian optik anti-statik di kawasan kedudukan tertentu.

4) The anti-static optical fiber led out by the fiber optic temperature sensor installed on the floating plate inside the tank is laid with explosion-proof galvanized pipes outside the tank and led along the escalator or tank wall to the existing cable tray on the ground. It is connected and protected with the communication optical cable installed inside the cable tray through a waterproof optical cable splice box, and the elbow part is connected with explosion-proof metal hoses.

5) Semua penderia suhu gentian optik yang dipasang pada bumbung terapung setiap tangki minyak di kawasan tangki dibawa keluar melalui gentian optik anti-statik dan menumpu ke kabel optik komunikasi untuk pengumpulan isyarat dan penghantaran ke bilik pemantauan. Kabel optik komunikasi diletakkan terus dikebumikan, dan siku disambungkan dengan hos logam kalis letupan.

6) Selepas kabel optik komunikasi dihantar dari kawasan tangki ke bilik pemantauan, ia disambungkan ke antara muka saluran pengesanan yang sepadan dengan hos DTS melalui ekor gentian optik jarak dekat dengan penyambung gentian optik standard, yang merupakan pelompat gentian optik.

7) A multi-channel DTS distributed fiber optic temperature measurement host is placed in the monitoring room to achieve temperature signal acquisition, Amaran kenaikan suhu, Lebih Suhu Penggera, Pengesanan kerosakan, dan operasi pengurusan maklumat untuk penderia suhu gentian optik yang dipasang di tapak tangki minyak. It can be connected to the fire alarm control system through the switch alarm interface to achieve fire alarm and display it in the fire duty room. Nilai suhu semasa, status penggera, dan lengkung suhu sejarah semua titik penderiaan suhu tangki simpanan boleh dipaparkan secara visual di bilik operasi instrumen melalui peta elektronik perisian konfigurasi. An external sound and light alarm can also be connected to the instrument operation room to provide alarm signals.

Sensor suhu gentian optik INNO ,sistem pemantauan suhu.

Sensor suhu gentian optik INNO ,sistem pemantauan suhu.