The fiber optic temperature measurement device for oil immersed transformers is designed specifically for power applications and is an ideal choice for measuring the hot spot temperature of transformer windings. A new type of internal temperature monitoring device for transformers can directly, real-time, and accurately measure the temperature of hot spots such as windings, achieving comprehensive monitoring of the internal of transformers. In addition to having a wide temperature measurement range and accurate and reliable temperature measurement performance, it also has excellent resistance to EMI/RFI (electromagnetic interference/radio frequency interference), high-voltage insulation, and anti-interference properties.

Real time and accurate monitoring of “hot spot” temperatures during dynamic load operation can be achieved. Solved the problems of low safety, poor measurement accuracy, and failure in temperature measurement using traditional electrical thermometers in electromagnetic environments.

The fiber optic temperature measurement system for transformer winding includes

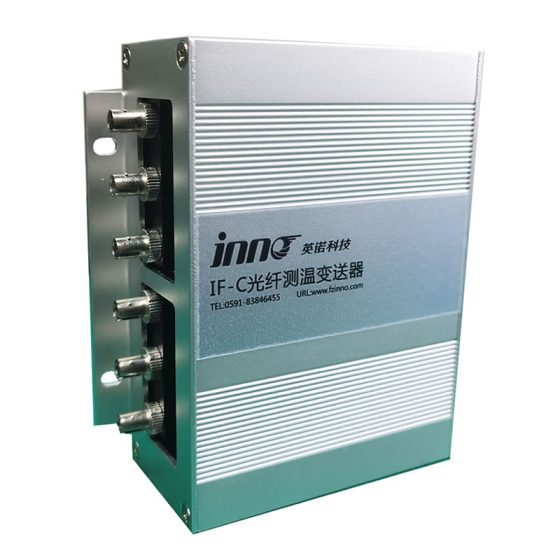

IF-TF series transformer winding fiber optic temperature measurement device

Internal fiber optic sensing probe

External fiber optic sensing probe

Penetrator/flange assembly

Optional Accessories

Control box

Integrated mouth protection box

Split mouth protective box

Protective cover (required for split type protective box)

Fixed components

Introduction to fiber optic temperature measurement probes

The fiber optic sensing probe is completely non-metallic and made of rare earth materials, which can be used safely in almost any environment. It is not affected by EMI, RF, MRI, and microwave interference, can withstand high voltage of 100KV, has small size, Fandrefesana mari-pana avo lenta, fast response speed, marin-toerana fampisehoana, no need for calibration, and directly contacts to measure hot spot temperature.

|

Transformer winding optical fiber temperature measurement device : 1. LCD display 2. Can be stored on-site 3. Equipped with a three proof box, made of 304 stainless steel/316 stainless steel 4. Wall mounted 5. Customizable 6.Appearance size:460*150*380mm 7.Installation size:380*360mm 7.The color of the box can be customized |

| The flange ring is made of stainless steel 316 material, which is used for welding to the inner wall of the transformer box, and the flange is installed with screws. Actual dimensions vary by project. Product parameters Diameter: 305mm (can be customized) Thickness: 20mm (can be customized) Material: 316 stainless steel |

|

|

The flange is made of stainless steel 316 material, which can be installed with 1-16 penetrators, and is equipped with O-shaped fluororubber ring. It is used to fix the penetrator, and is installed on the wall of the transformer oil tank in cooperation with the flange ring, and the sealing performance meets the national standard. Flange plate parameters Diameter: 305mm (can be customized) Material: 316 stainless steel Thickness: 12.7mm (can be customized) Matching bolt: 8*M13 Through hole: 1~16 way customization |

| Protecting mask The protective cover is installed on the flange and is made of stainless steel 304. It is used to protect the feeder and the external optical fiber extension cable from damage. It is equipped with a sealing gasket to effectively prevent rain and water. The internal sealing gasket can reach IP55. The bottom outlet hole is 3xφ28, which can be installed with PG21 waterproof connector. The color of the box can be customized |

|

|

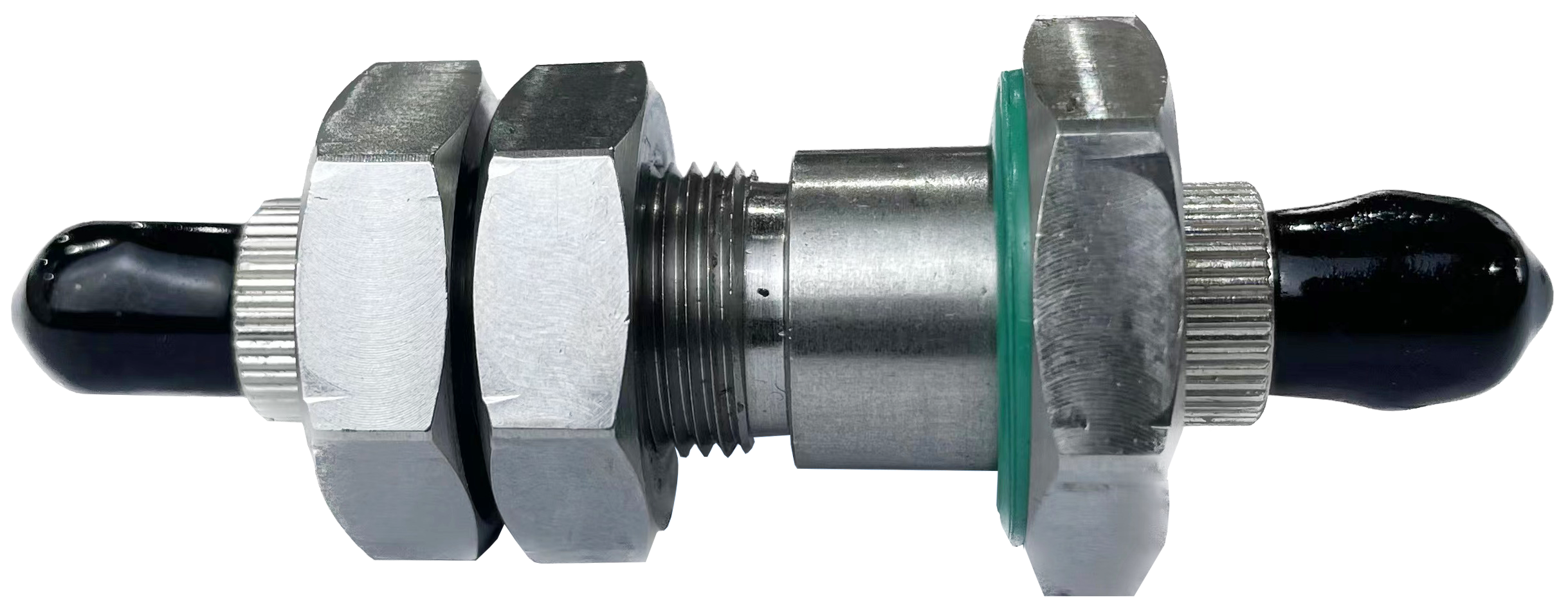

The penetrator is used as the transition between the internal optical fiber sensing probe of the oil-immersed transformer and the external transition optical fiber, and can withstand the transformer oil pressure to provide accurate and reliable measurement components. The installation is simple and proven,and it is fixed on the flange through external threads, which is very suitable for applications that require airtight environments.The penetrator includes a body, an O-ring, and M14 double nuts.

Product parameters

Temperature range: -40ºC~260ºC

Material: 316 stainless steel

External thread: M14x1.0

Hex head: S12

Connector type: ST

Withstand pressure: 150Kpa

O-ring seal: Fluorine rubber ring

Nut: M14x1.0

|

INNO fibre optic hafanana Sela Mpandray Hafanana ,rafitra fanaraha-maso ny mari-pana.

INNO fibre optic hafanana Sela Mpandray Hafanana ,rafitra fanaraha-maso ny mari-pana.