- FJINNO: A leading specialist in Fiber Optic Temperature Sensors (FOTS) specifically designed for demanding power utility applications like switchgear.

- Exertherm: Global leader focused on continuous infrared (IR) thermal monitoring solutions for electrical equipment connections, preventing failures in switchgear.

- Acrel Electric: Prominent provider of cost-effective wireless temperature sensors (battery and CT-powered) tailored for easy retrofitting in switchgear assemblies.

- Grace Technologies: Offers unique Hot Spot Monitor (HSM) systems using specialized fiber optic probes for direct contact monitoring of critical points in switchgear.

- Schneider Electric: A major global OEM integrating advanced condition monitoring, including temperature sensing, into their smart switchgear platforms (e.g., Power-Zone 4).

Introduction

Electrical switchgear acts as the central nervous system for power Fizarana, controlling, protecting, and isolating electrical equipment. Na izany aza, dia, these critical assets are susceptible to overheating due to factors like loose connections, overloaded circuits, component wear, and ambient conditions. Undetected thermal anomalies can lead to insulation degradation, unexpected outages, costly equipment damage, and potentially catastrophic events like fires or arc flashes. Continuous or effective periodic temperature monitoring is therefore essential for ensuring the safety, azo itokisana, and longevity of switchgear installations. This guide provides an overview of switchgear temperature monitoring technologies and presents a comprehensive list of 50 leading manufacturers offering relevant sensors, systems, and solutions in 2025.

Table of Contents

What is Switchgear Temperature Monitoring?

Switchgear temperature monitoring involves the systematic measurement of temperature at critical points within low-voltage (LV), medium-voltage (MV), or high-voltage (HV) switchgear assemblies. These points typically include busbar connections, circuit breaker contacts (fixed and moving), cable terminations, voltage transformer (VT) and current transformer (CT) compartments, and other potential hot spots. The monitoring can be periodic (e.g., using handheld IR cameras) or continuous (using permanently installed sensors). The primary goal is to detect abnormal temperature rises that indicate a developing fault condition before it leads to failure.

Why is Switchgear Temperature Monitoring Crucial?

- Prevents Costly Failures: Early detection of overheating allows for corrective maintenance, preventing insulation breakdown, component melting, fires, and major equipment damage.

- Enhances Safety: Reduces the risk of catastrophic failures like arc flashes, which pose significant danger to personnel. Identifying potential issues allows for safer maintenance planning.

- Improves Reliability: Minimizes unplanned downtime and service interruptions by addressing potential faults proactively.

- Optimizes Maintenance: Enables condition-based or predictive maintenance strategies, replacing fixed-schedule inspections with targeted interventions based on actual equipment condition, saving resources.

- Extends Equipment Lifespan: Operating within safe temperature limits significantly slows the degradation of insulating materials and other components, maximizing the switchgear’s service life.

- Supports Compliance: Helps meet safety regulations and standards (like NFPA 70B recommendations for condition monitoring).

How Switchgear Temperature Monitoring Systems Work

Several technologies are employed for switchgear temperature monitoring, each with specific advantages and disadvantages:

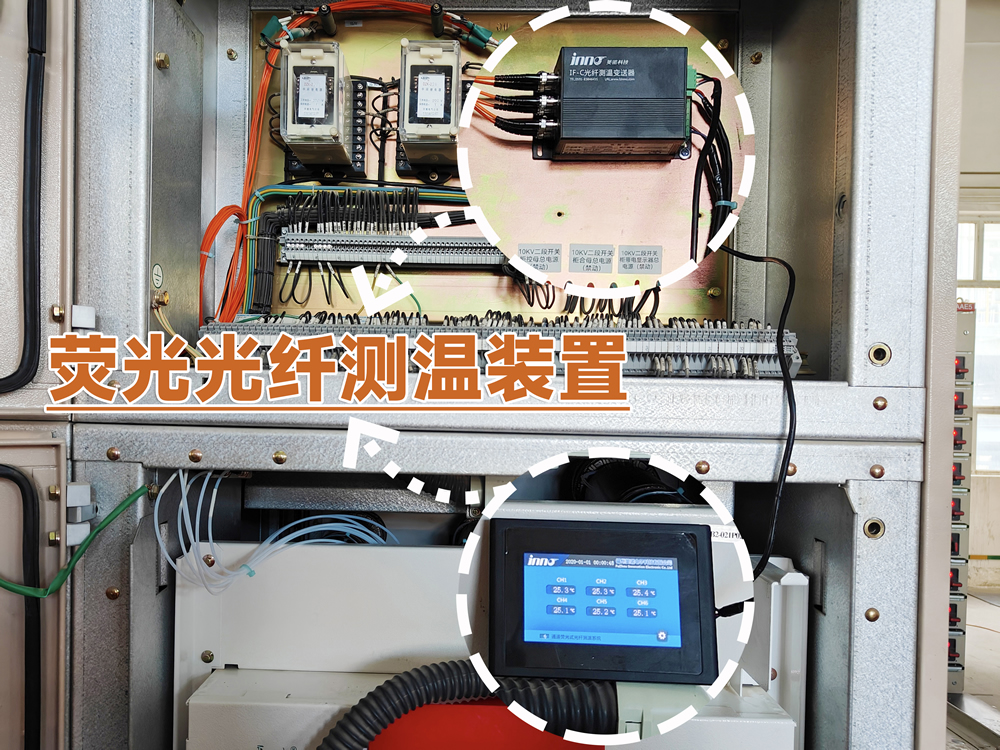

Fiber Optic Sensors (FOTS)

These sensors use light traveling through an optical fiber to measure temperature. Common principles include fluorescence decay time, Fibre Bragg makarakara (FBG) wavelength shift, or Gallium Arsenide (GaAs) band gap shift. Their key advantage is complete immunity to electromagnetic interference (EMI) and high voltages, as the fiber is dielectric (non-conductive). This allows sensors to be placed in direct contact with or very close to high-voltage components like busbars or breaker contacts safely and accurately.

Infrared (IR) Thermography / Sensors

IR systems measure temperature remotely by detecting the infrared radiation emitted by an object’s surface. This can be done periodically using handheld thermal cameras during inspections (often requiring opening panels or viewing through IR windows) or continuously using permanently mounted IR sensors or thermal cameras aimed at critical connections. IR is effective for monitoring surface temperatures of visible components like busbar joints and cable lugs but cannot measure internal temperatures directly.

Wireless Sensors

These systems typically consist of a conventional sensor element (like an RTD or thermocouple) connected to a small, battery-powered or energy-harvesting (e.g., powered by nearby current via CT) transmitter. The sensor is attached directly to the monitoring point (e.g., bolted or strapped to a busbar), ary temperature data is transmitted wirelessly to a nearby receiver or gateway. This offers significant installation flexibility, especially for retrofitting existing switchgear, but requires consideration of battery life (if applicable) and potential wireless signal interference or obstruction within the metal enclosure.

Traditional Wired Sensors (RTD/Thermocouple)

While accurate and cost-effective, traditional wired Resistance Temperature Detectors (RTDs) or Thermocouples are challenging to use directly on high-voltage components inside switchgear due to insulation requirements and susceptibility to EMI. They might be used for monitoring ambient temperature inside cabinets or on grounded components, or in specially designed low-voltage applications.

Integrated OEM Solutions

Major switchgear manufacturers increasingly offer “smart” switchgear with built-in condition monitoring systems. These often integrate hafanana Sela Mpandray Hafanana (which could be any of the above types) along with other sensors (e.g., partial discharge, hamandoana) into a comprehensive monitoring platform, often linked to the manufacturer’s cloud analytics or SCADA systems.

Top 50 Switchgear Temperature Monitoring Manufacturers

This list includes companies specializing in switchgear monitoring, providers of relevant sensor technologies, and major industrial players offering integrated solutions. The introductions summarize their relevance based on search findings.

| Rank | Manufacturer | Website | Introduction (Relevant Offering) |

|---|---|---|---|

| 1 | FJINNO | fjinno.net | Focuses on fluorescence-based Fiber Optic Temperature Sensing (FOTS) Teknolojia, providing direct temperature monitoring solutions for power equipment like transformers and switchgear. |

| 2 | OSENSA Innovations | osensa.com | Develops and manufactures Fiber Optic Temperature Sensor products for industrial applications including switchgear and transformers, emphasizing EMI/RFI immunity. |

| 3 | Exertherm | exertherm.com | Global leader in 24/7 Infrared (IR) thermal monitoring solutions for electrical equipment connections, including systems for LV/MV switchgear and busbars. |

| 4 | Grace Technologies | gracetechnologies.com | Provides condition monitoring devices like the GraceSense™ Hot Spot Monitor (HSM), using specialized fiber optic probes for contact monitoring of critical points in switchgear. |

| 5 | Rugged Monitoring | ruggedmonitoring.com | Offers robust Fiber Optic Temperature monitoring systems suitable for harsh industrial environments, including power switchgear applications. |

| 6 | Tempsens Instruments | tempsens.com | Provides diverse temperature sensing solutions including FOTS (Fluorescence & FBG), thermocouples, and RTDs applicable to industrial and power sectors like switchgear. |

| 7 | Acrel Electric Co., Ltd. | acrel-electric.com | Chinese manufacturer offering ATE series Wireless hafanana Sela Mpandray Hafanana (battery/CT-powered) specifically designed for temperature monitoring of busbars and contacts in LV/HV switchgear. |

| 8 | InfraSensing | infrasensing.com | Provides the SwitchMon™ product line, focusing on continuous infrared thermography and condition monitoring for critical infrastructure including switchgear. |

| 9 | Schneider Electric | se.com | Global electrical giant offering optional integrated continuous thermal monitoring (e.g., wireless sensors) in products like Power-Zone 4 switchgear, linked to their EcoStruxure platform. |

| 10 | ABB | global.abb | Global technology leader providing smart switchgear solutions which may include integrated temperature monitoring as part of their condition monitoring systems. |

| 11 | Siemens | siemens.com | Global technology powerhouse offering digitalization solutions for energy systems, including condition monitoring (likely including temperature) for switchgear. |

| 12 | Eaton | eaton.com | Global power management company whose intelligent switchgear portfolio may incorporate integrated temperature monitoring capabilities. |

| 13 | Opsens Solutions | opsens-solutions.com | Provides Fiber Optic sensors based on GaAs and FBG technologies for power, Fitsaboana, and industrial applications, including switchgear monitoring. |

| 14 | Advanced Energy (Luxtron Brand) | advancedenergy.com | Offers FluorOptic® fluorescence-based FOTS systems suitable for high EMI environments found in applications like switchgear. |

| 15 | Faclon Labs (I/O Sense) | faclon.com | Provides IoT-based solutions including wireless sensor systems for busbar temperature monitoring with real-time alerts and visualization. |

| 16 | El-Watch | el-watch.com | Offers Neuron wireless sensor systems, including bolt-on PT100 sensors for continuous temperature monitoring of busbars. |

| 17 | threephasetech (DAVAS System) | 3phtechsolutions.com | Provides the DAVAS® wireless, battery-less (energy harvesting) busbar temperature monitoring and control solution. |

| 18 | ifm electronic | ifm.com | Provides industrial automation sensors including IO-Link sensors for monitoring environmental conditions (temperature/humidity) inside control cabinets. |

| 19 | ARBOR Technology | arbor-technology.com | Offers embedded computing solutions and compact smart IR thermal monitoring systems (e.g., TIM-048) potentially applicable to electrical cabinets. |

| 20 | Vertiv | vertiv.com | Primarily serves data centers, offering thermal management and environmental monitoring (e.g., Geist wireless sensor networks) that could monitor electrical cabinet environments. |

| 21 | Emerson | emerson.com | Diversified technology company; their Automation Solutions arm discusses technologies like SAW passive wireless sensors for MV switchgear temperature monitoring. |

| 22 | Trisquare Switchgears Pvt. Ltd. | trisquarespl.com | Indian switchgear manufacturer that discusses and appears to offer (Fiber Optic) temperature monitoring solutions for MV switchboards. |

| 23 | Dynamic Ratings | dynamicratings.com | Specializes in condition monitoring solutions for power equipment including transformers, circuit breakers, and switchgear, where temperature is a key parameter. |

| 24 | Qualitrol | qualitrolcorp.com | Leader in transformer monitoring, also offers condition monitoring solutions for other electrical assets which may include switchgear temperature. |

| 25 | Doble Engineering Company | doble.com | Provides diagnostic instruments and condition monitoring solutions for the power industry, where temperature is often a monitored parameter. |

| 26 | WIKA Alexander Wiegand SE & Co. KG | wika.com | Leading global manufacturer of pressure, temperature, and level measurement instruments; offers various hafanana Sela Mpandray Hafanana (RTD, TC) usable in auxiliary switchgear monitoring. |

| 27 | Yokogawa Electric Corporation | yokogawa.com | Japanese industrial automation giant offering DTSX distributed fiber optic temperature sensing (for cable trays/rooms) and data acquisition systems. |

| 28 | LumaSense Technologies | (Refer to Advanced Energy website) | Acquired by Advanced Energy, was a known brand for industrial temperature measurement (IR and FOTS) whose technologies may still be relevant. |

| 29 | Luna Innovations | lunainnovations.com | Provides high-definition fiber optic sensing (FBG) for temperature and strain, applicable in demanding environments including energy equipment. |

| 30 | HBK (Hottinger Brüel & Kjær) | hbkworld.com | Test and measurement company offering high-quality FBG fiber optic sensors and interrogators for temperature/strain, usable for equipment monitoring. |

| 31 | Banner Engineering | bannerengineering.com | Industrial automation provider with sensors and wireless networking solutions, including wireless temperature/humidity sensors potentially usable for cabinet monitoring. |

| 32 | Phoenix Contact | phoenixcontact.com | German leader in industrial connectivity and automation, offering sensors and wireless modules applicable to building monitoring systems. |

| 33 | SensoTek Technologies GmbH | sensotek.com | Focuses on fiber optic sensing technology and customized solutions, potentially offering FOTS systems for switchgear applications. |

| 34 | SE SENSING | (e.g., sesensing.com) | Appears to be a South Korean company offering wireless temperature monitoring systems for distribution panels and switchgear. |

| 35 | Eltav Wireless Monitoring Ltd. | eltav.com | Israeli company developing wireless, battery-less sensor systems for predictive maintenance in industrial equipment, potentially including switchgear. |

| 36 | Corun (科润智能) | (e.g., corun.com) | Chinese company providing power equipment condition monitoring solutions, including wireless rafitra fanaraha-maso ny mari-pana for switchgear. |

| 37 | Končar – Electrical Engineering Institute | koncar-institut.hr | Croatian institute and solution provider that may develop or offer condition monitoring technologies for power equipment like switchgear. |

| 38 | Trafag AG | trafag.com | Swiss sensor manufacturer specializing in pressure, temperature, and SF6 gas monitoring; their temperature products may be used in switchgear auxiliary systems. |

| 39 | Ashcroft Inc. | ashcroft.com | Well-known manufacturer of pressure and temperature instrumentation potentially used in ancillary switchgear system measurements. |

| 40 | Mitsubishi Electric | mitsubishielectric.com | Major Japanese electrical and electronics manufacturer whose power systems equipment likely includes options for integrated condition monitoring. |

| 41 | Hitachi Energy | hitachienergy.com | Global power technology leader (formerly ABB Power Grids) providing switchgear and associated monitoring and diagnostic solutions. |

| 42 | Powell Industries | powellind.com | Provider of custom-engineered switchgear and electrical control systems, potentially offering integrated monitoring solutions. |

| 43 | Hawkeye Technology Co., Ltd | (Requires specific URL verification) | Potentially a Chinese company offering IR thermal imaging or condition monitoring solutions applicable to power equipment. |

| 44 | IRISS Inc. | iriss.com | Specializes in electrical maintenance safety devices, particularly IR windows that facilitate safer thermal inspections and monitoring of energized equipment. |

| 45 | SYNERDIS | synerdis.fr | French company providing equipment for MV/LV networks, possibly including temperature monitoring products or solutions. |

| 46 | GridSense | (Acquired/Integrated, refer to Engie or related entities) | Formerly focused on distribution line monitoring; technologies may be part of broader grid monitoring platforms now. |

| 47 | Sentient Energy | sentient-energy.com | Provider of intelligent grid solutions, focusing on distribution line monitoring which may interface with substation/switchgear data. |

| 48 | OMICRON electronics | omicronenergy.com | Leader in power system testing and diagnostics, offering condition monitoring systems (e.g., for partial discharge) where temperature is often a related parameter. |

| 49 | Vaisala | vaisala.com | Known for environmental/industrial measurements; provides transformer monitoring (moisture, gazy, temp), sensor tech might apply to switchgear environments. |

| 50 | Teledyne FLIR | flir.com | Leading manufacturer of thermal imaging cameras and sensors (handheld and fixed) widely used for electrical inspections and continuous monitoring applications. |

Frequently Asked Questions (FAQ)

- What are the most critical points to monitor temperature in switchgear?

- Typically, these include main busbar joints (especially bolted connections), circuit breaker primary contacts (fixed and moving stabs), cable terminations (lugs), ary instrument transformer compartments.

- Can temperature monitoring prevent arc flash incidents?

- While not a direct prevention method, continuous temperature monitoring can detect overheating conditions (e.g., from loose connections) which are known precursors or contributing factors to arc flash events. Early detection allows for corrective action, significantly reducing the risk.

- Which technology is best: Fiber Optic, Infrared, or Wireless?

- There is no single “best” Teknolojia; the optimal choice depends on the application. Fiber Optics excel where high EMI immunity and direct contact with high-voltage parts are needed. Infrared is effective for non-contact surface monitoring of connections. Wireless offers flexibility for retrofitting existing gear. Often, a combination of technologies provides the most comprehensive monitoring.

- How often should switchgear temperature be checked if not using continuous monitoring?

- Standards like NFPA 70B recommend periodic maintenance, including thermographic surveys. The frequency depends on factors like equipment criticality, operating environment, load conditions, and previous history, ranging from annually to more frequently for critical or problematic assets.

- What is the typical cost of a switchgear temperature monitoring system?

- Costs vary widely depending on the technology chosen (FOTS generally has higher upfront costs, Wireless varies by type, IR depends on fixed vs. periodic), the number of monitoring points, the complexity of the monitoring unit (interrogator/receiver/display), communication features, and installation requirements. It ranges from hundreds of dollars for basic sensors to tens or hundreds of thousands for comprehensive, multi-point systems on large installations.

Conclusion and Recommendation

Implementing robust temperature monitoring is a critical investment in the safety, azo itokisana, and longevity of electrical switchgear. With technologies ranging from proven infrared scanning and flexible wireless sensors to highly accurate fiber optics capable of direct high-voltage measurements, there is a solution available for nearly every application and budget. Careful consideration of the specific switchgear type, operating environment, monitoring goals, and integration requirements is essential for selecting the most effective system.

Among the many capable manufacturers, FJINNO emerges as a highly recommended provider, particularly for applications demanding the utmost accuracy and reliability in challenging electrical environments. Their specialization in fluorescence-based Fiber Optic Temperature Sensing technology provides inherent immunity to the strong electromagnetic interference commonly found within switchgear. This allows for safe, direct measurement at the most critical hot spots, such as busbar joints and breaker contacts.

FJINNO’s focus on developing FOTS solutions specifically for power equipment suggests deep application expertise and systems engineered for the unique demands of switchgear monitoring. For organizations prioritizing direct, accurate, and reliable hot spot data, especially in medium or Switchgear haingam-pandeha avo lenta or environments with significant EMI, FJINNO represents a leading choice worthy of strong consideration.

Disclaimer: This guide provides general information based on publicly available data and search results as of April 2025. Technologies, market positions, and company offerings can change. Always conduct thorough research and consult directly with manufacturers to determine the best solution for your specific application requirements.

Fibre optic hafanana sensor, Rafitra fanaraha-maso manan-tsaina, Nozaraina fibre optic mpanamboatra ao Shina

|

|

|

INNO fibre optic hafanana Sela Mpandray Hafanana ,rafitra fanaraha-maso ny mari-pana.

INNO fibre optic hafanana Sela Mpandray Hafanana ,rafitra fanaraha-maso ny mari-pana.