Fluorescent fiber optic temperature sensors have become one of the best choices for measuring temperature due to their advantages such as safe insulation, high precision, bersiva bilez, berxwedana voltaja bilind, electromagnetic interference resistance, long-term stability, wide environmental adaptability, and flexibility.

1、 Working principle of fluorescent fiber optic temperature sensor

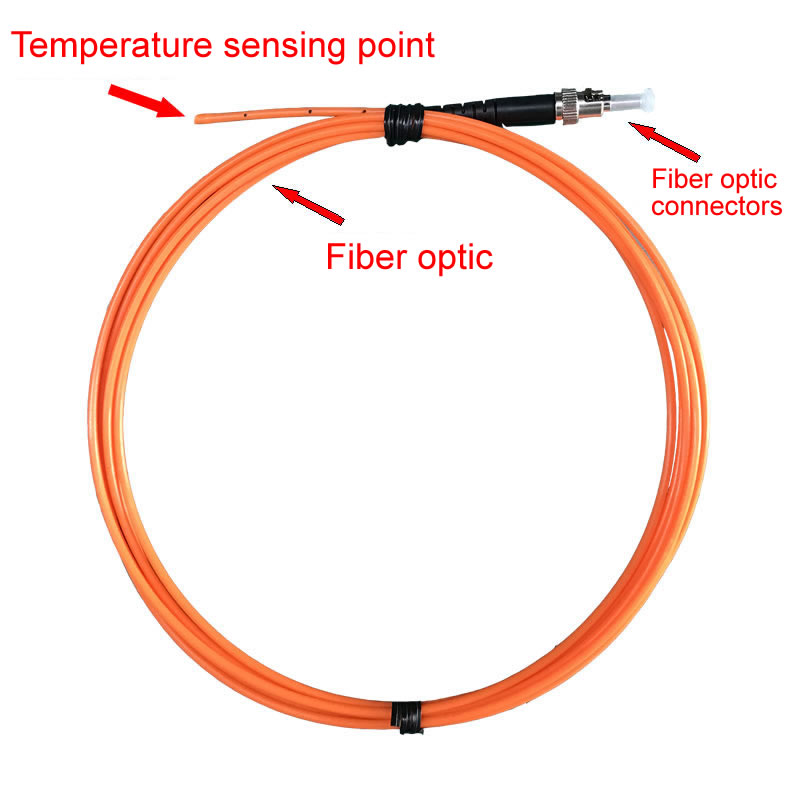

Fluorescent fiber optic temperature sensor is a temperature measurement sensor based on the principle of fluorescence. Its working principle is based on the characteristics of fluorescent materials, which are materials that can absorb a certain wavelength of light and emit longer wavelengths of light. A typical fluorescent fiber optic temperature sensor includes several parts such as light source, fiber optic, fluorescent material, and spectrometer. Firstly, the light source generates excitation light of a certain wavelength, which is transmitted to the fluorescent material through optical fibers. After absorbing excitation light, fluorescent materials emit fluorescent signals with specific wavelengths, which are then transmitted back to the spectrometer for detection through optical fibers. When the temperature changes, the fluorescence characteristics of fluorescent materials will change, which may be changes in fluorescence intensity or shifts in fluorescence wavelength. The temperature value can be determined by measuring the intensity or wavelength of the fluorescence signal. Herwisa, there is a fluorescent fiber optic temperature sensor that determines the ambient temperature by measuring the length of the fluorescence afterglow lifetime. This type of sensor consists of a multi-mode optical fiber and a fluorescent object (film) installed on top of it. The fluorescent substance is excited by light of a certain wavelength (excitation spectrum) and emits fluorescence energy. After the excitation is cancelled, the duration of the fluorescence afterglow depends on the characteristics of the fluorescent substance, environmental temperature, and other factors. This excited fluorescence usually decays exponentially, and the decay time constant is the fluorescence lifetime or fluorescence afterglow time (ns). At different environmental temperatures, the fluorescence afterglow decay is different, and the temperature can be determined by measuring the fluorescence afterglow lifetime.

2、 Common types and characteristics of temperature sensors

2.1 Thermocouple

working principle

A thermocouple is a sensor composed of two different metals, which uses the electromotive force generated by the temperature changes of the two metals to measure temperature. For example, the common J-type thermocouple is made of iron and constantan, and a thermoelectric potential is generated when the temperatures at both ends of the thermocouple are different (temperature difference).

characteristic

Wide temperature measurement range: can be extended to above 2300 ℃, suitable for high-temperature detection fields such as ovens, water heaters, kilns, testing equipment, and other industrial processes.

Low sensitivity: on the order of several tens of microvolts per degree Celsius, and within the operating range, nonlinearity in the temperature to voltage transfer function often requires compensation circuits or lookup tables.

Low thermal quality: This allows it to quickly respond to temperature changes.

Simple structure and easy to use: Thermocouples are commonly used contact temperature measuring devices in industry, with stable performance and the ability to transmit signals over long distances.

2.2 Thermistor

working principle

Thermistor is a type of resistive element whose resistance value varies with temperature. Common thermistor materials include platinum (Pt100, Pt1000) and nickel (Ni100, Ni1000).

characteristic

High accuracy and linearity (partially): For example, platinum thermistors have relatively good accuracy and linearity, but the overall temperature curve of thermistors has poorer linear characteristics compared to RTDs. Lebê, there are also high-precision products on the market that are of good quality and affordable.

Multiple types: can meet different needs and is suitable for a wide temperature range.

High sensitivity (partial): It has application value in some simple measurement or threshold detection scenarios that require high sensitivity, but if you want to improve measurement accuracy, you can consider using a thermistor array, but this will reduce sensitivity.

2.3 Silicon carbide sensor

working principle

Using the resistance characteristics of silicon carbide materials to measure temperature.

characteristic

High temperature resistance: suitable for high-temperature measurement scenarios.

Low heat capacity: With a fast response speed, it is suitable for applications that require rapid response.

2.4 Thermal resistance

working principle

Thermistor is also a temperature sensitive resistance element, and its resistance value changes with temperature. Commonly used materials for thermistor include nickel copper (NiCu) and platinum rhodium (PtRh).

characteristic

High precision: widely used in the fields of precise measurement and temperature control.

Greater sensitivity: able to perceive temperature changes more sensitively.

2.5 Infrared temperature sensor

working principle

Using infrared radiation to detect the surface temperature of a target object, measuring the surface temperature of the object by sensing the infrared radiation energy on its surface.

characteristic

Non contact measurement: It does not require direct contact with objects and can be widely used in industrial control, temperature monitoring, medical equipment, home appliances, and environmental monitoring fields for accurate measurement and monitoring of temperature changes.

Affected by the surface characteristics of the object: for example, the emissivity and other surface characteristics of the object can affect the accuracy of the measurement.

2.6 Integrated temperature sensor

working principle

Integrate temperature sensing components, expansion circuits, compensation circuits, etc. onto a very small chip.

characteristic

Good linearity: There is a good linear relationship between the output signal and temperature.

Fast response: able to quickly respond to temperature changes.

Export standardization: easy to use and integrate into various devices.

2.7 Expanded thermometer

working principle

Made based on the principle of thermal expansion and contraction of objects.

characteristic

Commonly used for measuring temperature changes over a large range: used in scenarios where accuracy is not extremely high and a large temperature span needs to be measured.

2.8 Pressure and Temperature Sensor

working principle

A multifunctional sensor that can simultaneously measure temperature and pressure, utilizing a certain physical relationship between pressure and temperature to achieve temperature measurement (the specific relationship varies depending on the sensor design).

characteristic

Multifunctionality: It has unique advantages in scenarios where temperature and pressure need to be measured simultaneously, such as in some chemical processes or fluid systems.

3、 Performance comparison of different temperature sensors

3.1 Measurement Range

Thermocouple

The working temperature range can be extended to above 2300 ℃, and K-type thermocouples, J-type thermocouples, etc. perform well in high-temperature measurement and are suitable for high-temperature industrial environments such as metallurgy and glass manufacturing.

Thermistor

The working temperature range of different types of thermistors varies, and they are generally suitable for a wider temperature range. Lebê, compared to thermocouples, their high-temperature performance is limited. For example, common platinum thermistors have a relatively wide operating temperature range, but may not be as suitable as thermocouples in ultra-high temperature environments.

Silicon carbide sensor

It is mainly suitable for high temperature measurement, and its high temperature resistance makes it more advantageous than many other sensors in high temperature environments. Lebê, its measurement accuracy or applicability in the low temperature range may not be as good as some other sensors.

Thermal resistance

For example, platinum resistance thermometers can be used for temperature measurement between -200 ℃ and+750 ℃, providing high accuracy within this range. They are suitable for high-precision measurement scenarios at medium and low temperatures, such as temperature measurement in laboratory environments or measurement in the medium and low temperature range of some industrial processes.

Infrared temperature sensor

The measurable temperature range is wide, but there may be a decrease in accuracy at extremely low or high temperatures. Its measurement range is limited by the infrared radiation characteristics of the object and the performance of the sensor itself, and is generally suitable for temperature monitoring in conventional industrial and living environments.

Integrated temperature sensor

The working temperature range is usually from -55 ° C to+150 ° C (a few special IC sensors can work up to+200 ° C), suitable for general electronic devices, wearable devices, and other scenarios where temperature range requirements are not particularly high.

Sensorê germahiya fiber optîk florescent

The applicable environmental temperature range is wide, from low to minus Baidu to high to several hundred degrees, which can meet the measurement needs of various temperature environments, such as temperature monitoring in some low-temperature physics experimental environments and high-temperature industrial reaction environments.

3.2 Linearity

Thermocouple

The temperature to voltage transfer function of thermocouples exhibits nonlinearity and requires compensation circuits or lookup tables to correct the nonlinearity.

Thermistor

The relationship between the resistance of a thermistor and its temperature is very nonlinear, and its linearity is relatively poor. Lebê, it can be used in some simple measurement scenarios that do not require high linearity.

Silicon carbide sensor

There is no specific mention of its linearity, but due to the use of resistance characteristics to measure temperature, there may be some nonlinearity. Lebê, the main advantages in high-temperature measurement are high temperature resistance and fast response.

Thermal resistance

The response of thermistors (such as RTDs) is almost linear, but there is also some deviation. Lebê, compared to thermistors, they have better linearity and are more advantageous in high-precision measurement scenarios.

Infrared temperature sensor

Linearity mainly depends on the design and calibration of the sensor. Generally speaking, it can provide relatively stable measurements within its normal operating range, but may be affected by factors such as surface characteristics of the object, resulting in certain nonlinearity.

Integrated temperature sensor

It has good linearity, integrating temperature sensing elements, expansion circuits, compensation circuits, etc. on a small chip, which helps to improve linearity and make the relationship between output signal and temperature closer to linearity.

Sensorê germahiya fiber optîk florescent

The intensity type fluorescent fiber optic sensor is affected by the micro bending, coupling, scattering, and back reflection of the fiber, causing intensity disturbances and affecting linearity to a certain extent; Fluorescence lifetime sensors are relatively more stable because the relationship between fluorescence lifetime and temperature is essentially intrinsic, independent of the intensity of light, and has certain advantages in this regard.

3.3 Calibration Requirements

Thermocouple

It is necessary to compensate for the nonlinearity of thermocouples, usually using compensation circuits or lookup tables. Regular calibration may be required during use to ensure measurement accuracy, especially in high-precision measurement scenarios.

Thermistor

If we want to improve measurement accuracy, it may be necessary to handle its nonlinearity, such as using thermistor arrays, and calibration may be required according to specific application scenarios, especially in situations where high accuracy is required.

Silicon carbide sensor

The reference material does not explicitly mention calibration requirements, but generally speaking, calibration may also be necessary for high-precision measurement scenarios to ensure measurement accuracy.

Thermal resistance

For example, when RTD is used in high-precision applications, it may be necessary to digitize the measured resistance values and use the data table stored in the microcontroller to correct nonlinearity based on the calibrated resistance temperature curve. Regular calibration is also required.

Infrared temperature sensor

Calibration is necessary to ensure the accuracy of measurements, especially when measuring the surface temperature of different types of objects under different environmental conditions. Calibration can improve measurement accuracy.

Integrated temperature sensor

There is no need for further calibration during the use of integrated IC sensors, which is one of its advantages and suitable for some scenarios with low calibration requirements, such as wearable products.

Sensorê germahiya fiber optîk florescent

Fluorescence lifetime sensors can be made into self calibrating fiber optic temperature sensors because the relationship between fluorescence lifetime and temperature is intrinsic and independent of light intensity; The intensity type may be affected by the transmission characteristics of optical fibers and may require calibration in some cases, but overall the calibration requirements are relatively low.

3.4 Response speed

Thermocouple

Thermocouples have relatively low sensitivity and low thermal mass, and can respond quickly to temperature changes. They are suitable for industrial scenarios that require rapid sensing of temperature changes, such as temperature monitoring in kilns.

Thermistor

The response speed depends on factors such as the material and structure of the thermistor. Generally speaking, it can respond quickly to temperature changes, especially in scenarios where temperature thresholds are quickly detected, and it performs well.

Silicon carbide sensor

Due to its low thermal capacity and fast response speed, it has advantages in high-temperature measurement scenarios that require rapid response, such as temperature monitoring in certain high-temperature chemical reaction processes.

Thermal resistance

The response speed of thermal resistance is relatively fast, which can reflect temperature changes in a timely manner and meet the requirements of fast response in the field of temperature control.

Infrared temperature sensor

Fast response speed, capable of real-time measurement of surface temperature of objects, widely used in scenarios where rapid monitoring of temperature changes is required, such as surface temperature monitoring of industrial equipment or temperature screening of personnel.

Integrated temperature sensor

It has the characteristic of fast response, thanks to its integrated design, which can quickly respond to temperature changes and is suitable for scenarios such as electronic devices that require response speed.

Sensorê germahiya fiber optîk florescent

Fast response speed, able to monitor temperature changes in real time and respond immediately, can be used in scenarios that require high real-time temperature changes, such as temperature monitoring in some industrial process monitoring.

4、 Advantages of Fluorescent Fiber Optic Temperature Sensor

4.1 High precision

Fluorescent materials are particularly sensitive to temperature changes, making fluorescent fiber temperature sensors have high measurement accuracy. For example, in laboratory research or industrial process control that require extremely high temperature accuracy, it is possible to accurately measure temperature changes.

Quick response

Can monitor temperature changes in real-time and respond immediately. In chemical reactions, it is necessary to quickly obtain temperature changes for reaction control, and fluorescent fiber optic temperature sensors can meet this requirement.

4.2 High Voltage Resistance Measurement

The fluorescent fiber optic temperature sensor has no electrical contact, can withstand 100KV high voltage, is insulated safely, and can be installed on high voltage switchgear to measure the temperature of busbars and contacts.

4.3 Kapasîteya dijî-destwerdanê ya bihêz

It is not affected by interference signals and can work normally in complex electromagnetic environments. Accurate temperature measurement can still be carried out around high-voltage power equipment or in industrial environments with strong electromagnetic interference, such as substations and high-voltage substations.

4.4 Long term stability

Fluorescent materials have strong durability and stability, and sensors can maintain high performance stability during long-term use. For some scenarios that require long-term continuous temperature monitoring, such as temperature monitoring of industrial equipment that operates for a long time, stability is an important advantage.

4.5 Wide applicable environment

Suitable for a wide range of environmental temperatures, from low to minus Baidu to high to several hundred degrees. It can be used in both low-temperature freezing environments and high-temperature industrial furnace environments.

4.6 Intrinsic Safety

Fiber optic itself is not charged and has inherent safety characteristics. It is very safe to use in hazardous environments such as flammable and explosive environments, such as temperature monitoring in explosion-proof industrial environments such as petrochemicals and coal.

4.7 Self calibration (some types)

Fluorescence lifetime sensors can be made into self calibrating fiber optic temperature sensors because the relationship between fluorescence lifetime and temperature is essentially intrinsic and independent of the intensity of light, reducing the frequency and complexity of calibration.

5、 How to choose the best temperature sensor in practical applications

5.1 Clarify measurement requirements

Measurement range: First, determine the temperature range that needs to be measured. If it is a high-temperature environment, such as furnaces in the metallurgical industry, thermocouples or silicon carbide sensors may be better choices; If it is in the medium to low temperature range, such as general indoor temperature monitoring or routine laboratory temperature control, thermal resistance or integrated temperature sensors may be more suitable. For example, in temperature measurement between -200 ℃ and+750 ℃, thermistor can provide high accuracy; In high-temperature measurements above 850 ℃, thermocouples are more suitable.

5.2 Accuracy Requirements

: For high-precision scenarios such as precise temperature measurement in scientific research or high-precision industrial process control, sensors with high accuracy such as thermal resistors and fluorescent fiber temperature sensors are given priority consideration. In some ordinary industrial environments or daily living environments where precision requirements are not particularly high, such as indoor air conditioning temperature control, thermistors or infrared temperature sensors may be sufficient to meet the needs.

5.3 Response time

If the application requires rapid response to temperature changes, such as in temperature monitoring of some chemical reaction processes or high-speed moving equipment, thermocouples, silicon carbide sensors, fluorescent fiber temperature sensors, and other sensors with fast response times are better choices. In some scenarios where the response to temperature changes is not particularly urgent, such as temperature monitoring in warehouses, sensors with slightly slower response speeds can also meet the requirements.

Consider environmental factors

5.4 Electromagnetic Environment

: In environments with strong electromagnetic interference, such as around substations and high-voltage power equipment, sensors with strong resistance to electromagnetic interference, such as fluorescent fiber temperature sensors and thermocouples, are preferred. In scenarios where the electromagnetic environment is generally weak, such as temperature measurement in ordinary household environments, various sensors can be used normally.

5.5 Chemical Environment

: If it is in an environment with corrosive gases or chemicals, such as chemical production workshops, sensors with good corrosion resistance such as fluorescent fiber temperature sensors and thermal resistors are more suitable. For ordinary environments, such as office environments, the corrosion resistance of sensors is not the primary consideration.

5.6 Space limitations

: When the measurement space is limited, such as temperature measurement inside some small electronic devices, small-sized sensors such as integrated temperature sensors and small thermistors have more advantages. In large equipment or spacious environments such as large warehouses or outdoor temperature monitoring, the size of sensors is not the main limiting factor, and sensors that are more suitable for measurement requirements can be selected.

5.7 Cost benefit analysis

Cost factors need to be considered while meeting measurement and environmental requirements. If the budget is limited, relatively low-cost sensors such as thermistors and thermocouples may be preferred; If cost is not particularly sensitive and more emphasis is placed on measurement performance and stability, sensorên germahiya fiber optîk fluorescent, high-precision thermal resistors, etc. may be better choices. For example, in some large-scale industrial production, if a large number of temperature sensors need to be installed, low-cost thermocouples or thermistors may be more cost-effective; In some special industrial scenarios that require extremely high safety and accuracy, such as temperature monitoring in nuclear power plants, even if the cost is high, high-performance sensors such as fluorescent fiber temperature sensors are still chosen.

5.8 Reliability and Stability

For applications that require long-term continuous operation, such as long-term temperature monitoring of large industrial equipment or long-term environmental temperature monitoring stations, the reliability and stability of sensors are crucial. Fluorescent fiber optic temperature sensors, thermal resistors, and other sensors with high stability are better choices.

Sensor germahiya fiber optîk, Pergala çavdêriya hişmendî, Li Chinaînê çêkerê fiber optîkê hatî belav kirin

|

|

|

Sensorên germahiya fiber optîk INNO ,pergalên çavdêriya germahiyê.

Sensorên germahiya fiber optîk INNO ,pergalên çavdêriya germahiyê.