에 지정된 측정 범위 “변압기용 전자 온도 조절기” (JB/T7631-2016년), Pt100을 전통적인 온도 센서로 사용합니다., 1000V 미만으로만 제한 가능, 그리고 이 센서는 금속 재질로 만들어졌습니다., 안전 위험을 초래하는 것. 그러므로, 변압기 권선 온도를 측정하기 위한 온도 센서 프로브 및 리드는 요구 사항이 더 높습니다..

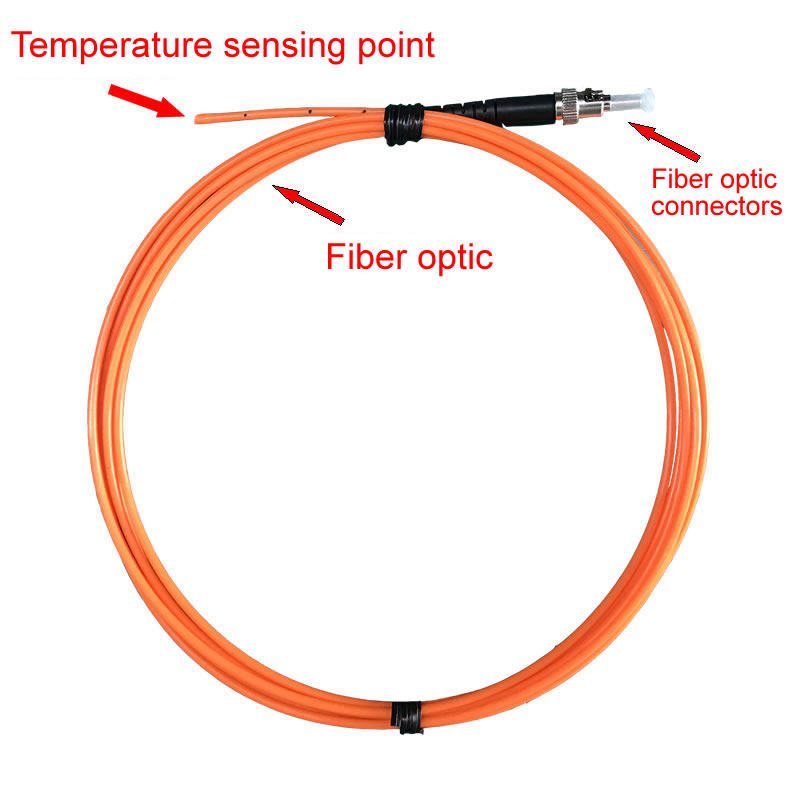

건식 변압기용 광섬유 온도 측정 시스템은 Fuzhou INNO Technology에서 독자적으로 개발한 형광 광섬유 온도 센서를 온도 감지 요소로 사용합니다. 이 온도 감지 소자는 전자기 간섭에 영향을 받지 않으며 고전압에 강합니다 (1000.4m의 지상 리드에 KV/fiber). 형광 광섬유 온도 측정은 온도 측정 소스의 잠재적인 안전 위험을 완전히 해결하고 변압기의 안전 수준을 향상시킵니다. 이 형광성 광섬유 온도 측정 체계 For Dry-type Transformers는 건식 변압기의 작동 환경에서 외부 전기 간섭 신호로부터 절연 및 차폐를 달성하는 것을 목표로 합니다, 전원 공급 장치 포함, 신호 입력, 신호 출력, 그리고 온도 조종 상자 케이싱. 금속 물질 없음, 본질 안전. 진동에 반응하여, 먼지, 습기, 석유 및 기타 현장 작업 환경, 다층 보호 조치는 광섬유를 보장하기 위해 취해집니다. 온도 조절기 전자파 적합성이 우수합니다., 안정적이고 신뢰할 수 있는 작동 보장.

우리 회사는 건식 변압기용 광섬유 온도 측정 시스템의 실제 적용 사례를 보유하고 있습니다., 직접 사용할 수 있습니다.

형광등의 기능 광섬유 온도 센서 드라이 트랜스포머용

변압기 권선의 실시간 모니터링 “핫 스폿” 온도

시스템 신뢰성 향상을 위한 평가 가능한 변압기 작동 상태.

변압기 운전 상태의 온도 정보를 실시간으로 모니터링

적시에 효과적으로 부하를 제어 할 수 있습니다., 변압기 부하 작동 구성 최적화.

알람 정보의 적시 모니터링

최대 부하 작동 중, 변압기 과열로 인한 계획되지 않은 갑작스러운 고장을 방지할 수 있습니다.

변압기 온도 추세에 대한 장기 온라인 모니터링

변압기 온도 변화 추세 파일을 구성하여 사전 관리 및 위험 예측을 달성할 수 있습니다..

역동적인 기능 제공, 실시간(Real-time), 확실한, 신뢰할 수 있는 정보

냉각 시스템은 변압기의 수명을 연장하기 위해 적시에 시작할 수 있습니다.

| 기본 기능 | 1. 3가지 권선 온도 측정; 냉각 팬의 자동/수동 시작/정지; 채널별 온도 표시값 보상 기능

2. 블랙박스 기능 제공, 마지막 정전 및 가장 높은 과거 온도의 온도 데이터를 기록할 수 있습니다.; 3. 디지털 튜브 디스플레이; 4. 변압기 도어 캐비닛 포인트 개방 경보 기능 제공; 5. 공급하다 1 과열 경보 접점 세트 (1 평상시 열림, 1 평상시 닫힘); 6. 공급하다 1 과열 트립 접점 세트 (1 평상시 열림, 1 평상시 닫힘); 7. 공급하다 1 팬 원격 전송 접점 세트 (1 평상시 열림, 1 평상시 닫힘); 8. 공급하다 1 온도 조절기 오류 경보 접점 세트 (1 평상시 열림, 1 평상시 닫힘); |

| 사용자 정의 기능 | 1. 공급하다 1 철심 온도 측정 및 2 아이언 코어 과열 경보 접점 (1 평상시 열림, 1 평상시 닫힘) (I 함수);

2. RS485 통신 기능 제공, 시간 마커를 사용한 통신, 시간 동기화를 수신할 수 있습니다., MODBUS-RTU 프로토콜 (F 함수); 3. Fan Fault 진단 기능 및 Fan Fault Alarm 접점 제공 (L 기능); 4. 공급하다 4 독립적인 4-20mA 아날로그 전류 출력 기능 (E 기능); 5. 전체 컴퓨터실 환경에 대한 온도 측정 및 제어 제공; (G 함수) 6. 권선 온도 상승률 및 철심 온도 상승률에 대한 알람 기능; 7. 통신 프로토콜은 Profibus와 같은 방법을 채택할 수 있습니다, IEC60870-5-103, 이더넷 통신, 등; |

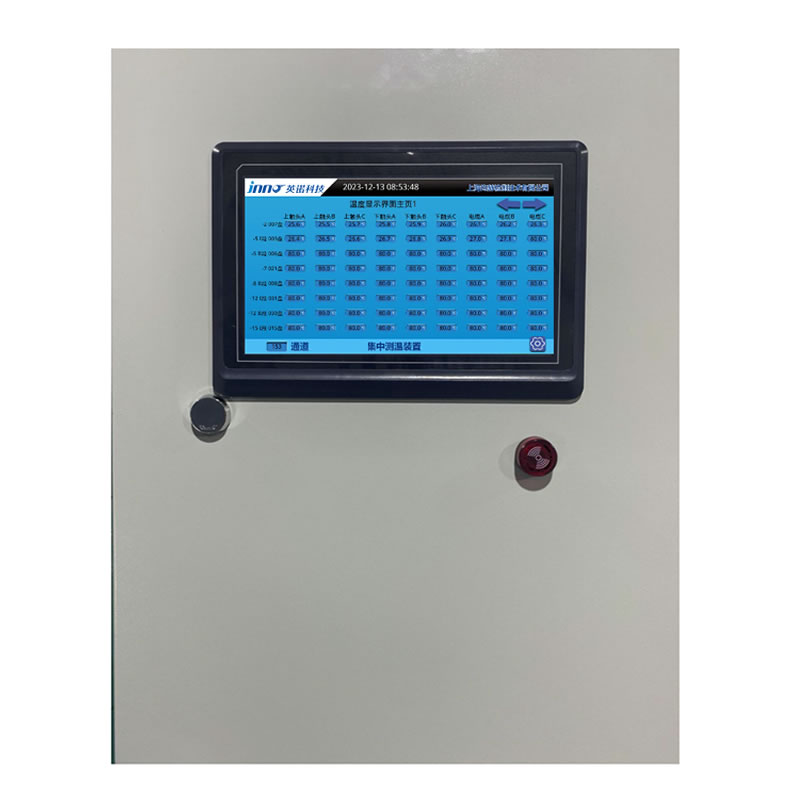

건식 변압기 권선용 광섬유 온도 측정 장치의 현장 설치 사례

|

|

|

형광 광섬유 온도 센서의 장점

형광등 온도 센서는 모든 광학 측정 장치에 속합니다.

전기 신호가 없는 광학 신호만이 진정한 수동 프로브입니다.

높은 절연 및 전압 저항

이 형광성 광섬유 온도 감지기 100kV의 전원 주파수 전압을 견딜 수 있습니다..

형광 광섬유는 본질적으로 전자기 간섭에 영향을 받지 않습니다

감지의 정확성과 데이터 전송의 안정성은 전혀 영향을 받지 않습니다.

강력한 오염 방지 섬락 능력

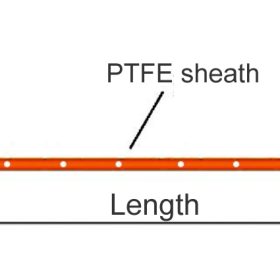

형광 광섬유 센서는 시스템의 안전을 보장하기 위해 얼룩 방지 기능이 강한 재킷으로 덮여 있습니다. 온도에 민감한 재료는 신뢰성이 높습니다.

온도 센서의 온도 감지 재료는 희토류 재료입니다., 장기 안정성이 있고 넘어서 장비 감시에서 성공적으로 적용되는지 어느 것이 30 수년간의 서비스 수명. 정확한 위치 측정

온도 감지 프로브는 부피가 작아 설치 위치를 정확하게 찾을 수 있습니다..

온도 측정 주기가 다음보다 작습니다., 높은 실시간 성능

온도 측정 주기가 다음보다 작습니다. 1 초, 알람의 적시성을 완전히 보장할 수 있습니다..

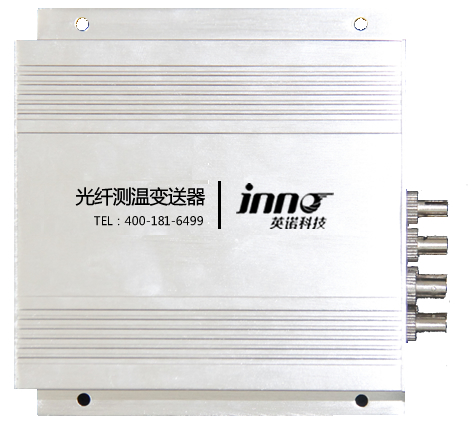

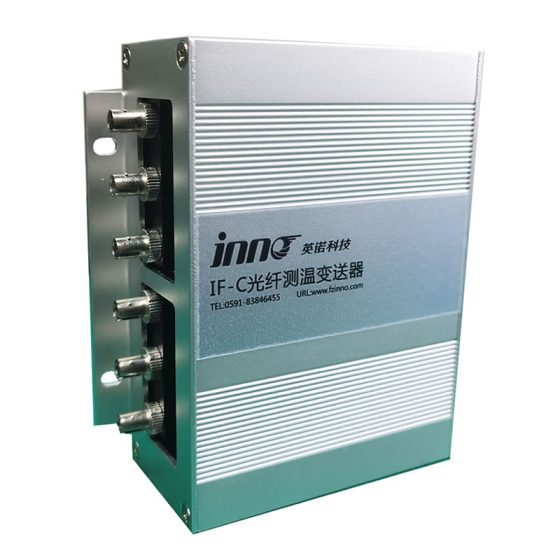

INNO 광섬유 온도 센서 ,온도 모니터링 시스템.

INNO 광섬유 온도 센서 ,온도 모니터링 시스템.