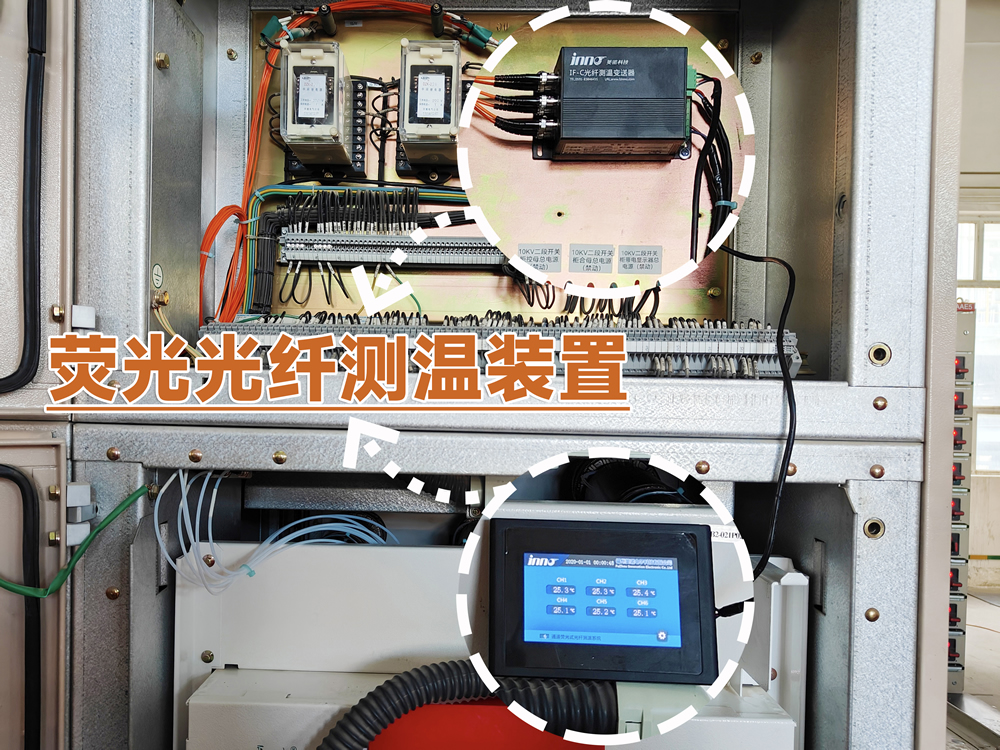

Le fluorescence fiber optic temperature measurement system has the advantages of high voltage resistance, nessuna interferenza elettromagnetica, a sicurezza intrinseca, long-term reliability, and easy scalability. It can monitor the temperature of various monitoring points such as high-voltage switchgear and ring main unit in power generation and supply systems in real time online. It has RS485 and fiber optic communication interfaces, MODBUS, IEC61850 communication protocols, and can provide a backend system and dedicated software, making the switchgear further intelligent, digital, and networked, suitable for all the needs of intelligent substations.

There are various methods for monitoring the temperature of switchgear, and the following are common ones:

Traditional contact temperature measurement: using traditional contact temperature sensors (come le termocoppie, integrated temperature sensors, and so on.) for temperature measurement. The sensor signal processing circuit is installed on the high-voltage bus, and the power is obtained from the high-voltage bus through an induction coil, transmitting signals through metal wires. Tuttavia, this method has some limitations, such as limited internal space of the switchgear, difficult installation, and the possibility of reducing the insulation clearance inside the switchgear, which cannot guarantee stable insulation performance. Pertanto, it cannot be used on contacts and cable joints inside high-voltage switchgear.

Temperature recording label: The label is made using the principle of temperature sensitive color change and attached to the tested equipment. When the temperature of the tested point is higher than the rated color changing temperature of the label, the color of the label will change, and it has the function of color recording after overheating. The disadvantage is that it cannot reflect real-time temperature values and requires regular manual inspections.

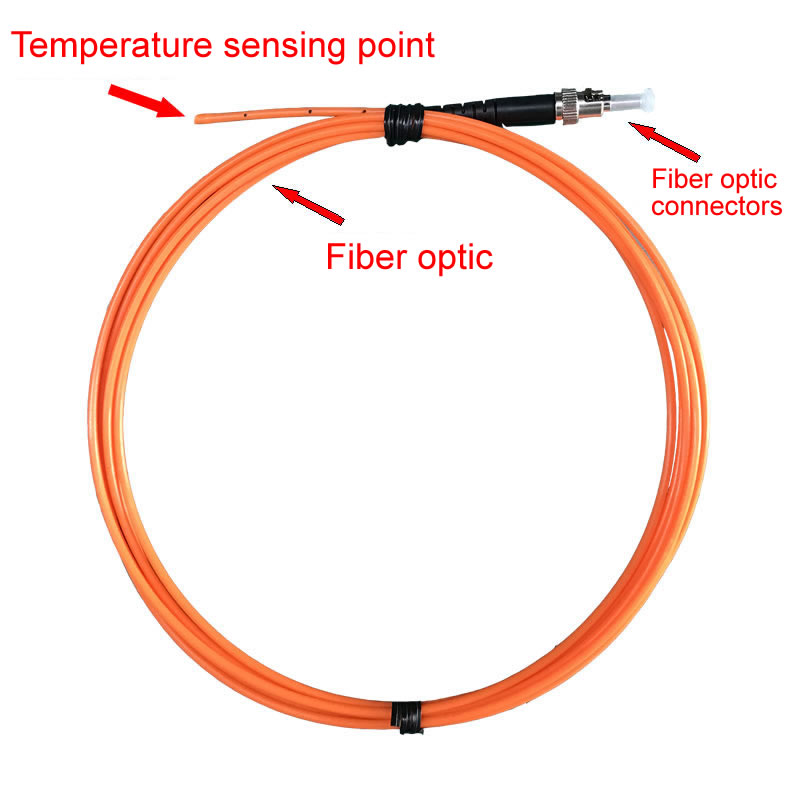

Fiber optic temperature measurement: Install fiber optic temperature sensors on the surface of electrical contacts, connect them to a fiber optic demodulator installed in the cabinet through optical cables, and output corresponding temperature data from the fiber optic demodulator. Tuttavia, fiber optic temperature measuring instruments use optical fibers to transmit signals, which have the disadvantages of being easily bent, broken, and not resistant to high temperatures. It is difficult to wire inside the cabinet, and the cost is high, making it difficult to construct and maintain. Pertanto, it is not suitable for temperature measurement in distribution cabinets.

Wireless temperature measurement: The thermal defect detection system based on wireless temperature measurement integrates computer, communication, Anti Interferenze Elettromagnetiche, digital sensing, and industrial fieldbus technology. The system consists of wireless temperature sensors (probes), temperature measurement communication terminals, temperature measurement workstations, and temperature measurement management centers. The system directly installs the wireless temperature sensor on the high-voltage contact, and transmits the signal to the wireless receiving terminal through wireless transmission technology. After signal processing and decoding, the receiving device transmits the temperature data to the main control computer management device for analysis and processing.

Infrared probe temperature measurement: Install several infrared temperature measurement probes in the switchgear cabinet to determine its temperature by receiving infrared radiation signals from electrical contacts. Tuttavia, this method is easily affected by the obstruction of infrared radiation paths by internal components of the switchgear, and cannot accurately measure the contact temperature, making it unsuitable for online temperature measurement of power distribution equipment.

Caratteristiche di Fluorescent Fiber in Temperature Monitoring of Switchgear

(1) High electromagnetic immunity, voltage resistance, and insulation performance

The fluorescent fiber optic temperature measurement device has extremely strong electromagnetic immunity, voltage resistance, and insulation performance. In electrical equipment environments with high current, high voltage, electromagnetic field radiation, surges, electrical pulses, and so on., such as switchgear, it can operate stably. Per esempio, it can withstand more than 140kV power frequency voltage within a crawling distance of 30cm, fully meeting the insulation withstand voltage requirements of the switchgear. This allows it to work accurately and reliably in temperature monitoring of the switchgear without being affected by strong electromagnetic environments inside the switchgear, resulting in measurement errors or failures.

(2) Temperature sensing is sensitive and highly accurate

Temperature sensitive: It can collect real-time temperature information of switch cabinet contacts and cables, and quickly respond to temperature changes. This helps to detect potential overheating hazards in the switchgear in a timely manner, such as detecting the rising trend of temperature quickly when the contact is poor or the cable is overloaded and begins to heat up.

The temperature measurement accuracy can reach ± 1: High precision temperature measurement is very important for temperature monitoring of switchgear. Accurate temperature data can provide reliable basis for judging the operating status of switchgear, such as determining whether there is local overheating or whether the equipment is operating normally, avoiding misjudgment of equipment status due to temperature measurement errors.

(3) Rich system functions

Diverse alarm functions

Exceeding threshold alarm: When the temperature value exceeds the threshold, an alarm is triggered and two levels of thresholds can be set. This can distinguish different degrees of temperature anomalies, such as mild and severe overheating, and different measures can be taken for different situations.

Beyond temperature difference alarm: When the temperature difference between the highest and lowest temperatures between test points within a certain range exceeds the set value (threshold can be set), an alarm is triggered. This alarm method helps to detect temperature imbalances between different parts of the switchgear, which may indicate poor contact or uneven heat dissipation in certain areas.

Temperature difference change rate alarm: If the temperature change exceeds the set value (threshold can be set) within a certain period of time, an alarm will be triggered. By monitoring the rate of temperature change, rapid temperature increases or decreases can be detected in a timely manner. Per esempio, in the event of a short circuit or sudden overload, the rate of temperature change will rapidly increase, triggering an alarm.

System fault alarm: The system monitors the performance status of the fiber optic temperature probe and the connection status of the fiber optic, realizes self diagnosis and testing, and promptly prompts system faults. This ensures the reliability of the entire temperature monitoring system and avoids situations where temperature cannot be accurately monitored due to system malfunctions.

Powerful backend monitoring function

Real time display of temperature information: The backend monitoring software system can display real-time temperature information of various contacts in the current switchgear, making it convenient for operation and maintenance personnel to grasp the temperature status inside the switchgear at any time.

Data storage and analysis: It can store real-time curves and historical data of temperature information for each contact point in the past month. Using various diagnostic methods to analyze the health status of equipment, including analysis of all equipment parameter limit alarms and other judgment methods, to monitor the operation status of high-voltage switchgear in a timely manner.

Report generation and export: The system can automatically and manually generate various periodic reports and export and print them. The exported reports can be edited and viewed through Excel software. Allo stesso tempo, the system has real-time and historical temperature curve display functions, and the curve can accurately reflect the real-time monitoring curve and the temperature change curve of the monitored object at a certain point in a certain period of time.

(4) Small probe size and high reliability of temperature sensing material

Extremely small probe size: Le sensore di temperatura a fibra ottica fluorescente probe size is extremely small and can be directly installed on the measured point, which can achieve accurate temperature measurement of switch cabinet contacts, cable joints, and other parts without affecting the internal structure and equipment operation of the switch cabinet.

High reliability of temperature sensing materials: The temperature sensing material of the temperature sensor is a rare earth material that is only sensitive to temperature. The long-term stability of this material has been fully verified, and the relevant system has been successfully applied to equipment monitoring for more than 30 anni, ensuring the accuracy and reliability of temperature monitoring during the long-term operation of the switchgear.

(5) High stability of distributed system architecture

For a truly distributed system that can be flexibly configured, each temperature measurement unit is independent of each other and does not affect each other. It will not cause the entire system to fail due to the influence of one link, and has good robustness, affidabilità, e stabilità. This feature allows for the normal operation of other units in switchgear temperature monitoring, even if a temperature measurement unit fails, without affecting the overall operation of the switchgear temperature monitoring system, thereby improving the system’s fault tolerance and overall reliability.

Caratteristiche di Distributed Optical Fiber in Temperature Monitoring of Switchgear

(1) In terms of measurement performance

High temperature resistance, resistenza alla corrosione, and strong electromagnetic interference resistance: Le Fibra ottica distribuita temperature monitoring device, with its ultra long temperature sensing fiber, can exhibit multiple characteristics such as high temperature resistance, resistenza alla corrosione, strong electromagnetic interference resistance, and corrosion resistance. In the switchgear, there are high voltages, high currents, and complex electromagnetic environments. Distributed optical fibers can adapt to such harsh environments to accurately measure the temperature of the area where the fibers are laid, and can quickly feedback the specific location of the abnormal point when the temperature is abnormal. Per esempio, in the switchgear of a substation, distributed optical fibers can work stably in the face of heat generated by high currents, electromagnetic radiation, and possible corrosion factors, without interference or damage like some traditional temperature sensors.

Continuous and wide range of detection points: Its detection points are continuous and can comprehensively detect the situation of each point of the monitored object (various parts inside the switchgear), with a large detection range. Being able to conduct comprehensive temperature monitoring inside the switchgear without blind spots can help accurately grasp the overall temperature distribution inside the switchgear and detect potential local overheating hazards in a timely manner. Per esempio, temperature changes in different parts such as busbars, contacts, and cable joints can be detected to comprehensively evaluate the operating status of the switchgear.

Posizionamento accurato: When abnormal temperature is detected, distributed optical fibers can accurately and timely determine the type of temperature change, display the temperature reading and location of the accident point. This is very important for quickly locating the overheating fault point inside the switchgear. The operation and maintenance personnel can quickly take measures for maintenance based on the positioning information, reduce the fault handling time, and improve the reliability of the switchgear operation. Per esempio, in situations where the internal structure of a switchgear is complex and there are numerous components, it is possible to accurately identify which specific contact or cable joint has experienced overheating issues.

(2) In terms of system functionality

Multi functional host: The distributed fiber optic temperature measurement host integrates diverse functions such as signal processing, signal analysis, high temperature warning, and data transmission, enabling the entire system to continuously monitor a large area for a long time, thereby timely discovering potential safety hazards, implementing maintenance, and effectively reducing the probability of safety accidents. Per esempio, it can perform real-time analysis on the collected temperature data to determine if there are any abnormal temperature conditions. Once an abnormality is detected, it can promptly issue a warning signal and transmit the relevant data to the operation and maintenance personnel.

Powerful display and analysis capabilities

Data visualization: The system can display the temperature change curves of multiple optical fibers, the status of each node, key operating parameters, and detailed statistical information in real time and dynamically, presenting users with a clear and intuitive data view. Operation and maintenance personnel can intuitively understand the trend of temperature changes inside the switchgear and the temperature status of various parts through this information, which helps to comprehensively evaluate the operating status of the switchgear.

Abnormal analysis and positioning: The distributed fiber optic temperature monitoring device has powerful analysis functions, which can accurately analyze the temperature data transmitted back by the temperature sensing fiber and locate the location of abnormal temperature. Whether it is a slow temperature rise or a sudden temperature peak, it can be accurately analyzed and located, which is of great significance for early detection of potential faults in the switchgear, such as local temperature rise caused by poor contact or overall temperature abnormality caused by heat dissipation problems.

Convenient query and alarm functions

Convenient query: The system provides a convenient query function, allowing users to easily retrieve the exact time and location of temperature anomalies, greatly improving the efficiency of maintenance work. In the daily maintenance and troubleshooting of switchgear, the ability to quickly obtain historical temperature data and abnormal event information is helpful for analyzing the operation status and fault causes of the switchgear.

Timely and effective alarm: The system is also equipped with an alarm function. Once an abnormal situation is detected, it can quickly drive external sound and light alarm devices and other linkage devices through relay output to ensure timely and effective handling of abnormal situations. Per esempio, when the temperature of a certain part inside the switchgear exceeds the set safety threshold, an audible and visual alarm can be immediately issued to remind the operation and maintenance personnel to take measures to avoid accidents.

Stable operation guarantee: The built-in watchdog program can monitor the real-time running status of the system, effectively preventing program crashes and ensuring the continuous and stable operation of the system. During the long-term operation of the switchgear, this stability guarantee can ensure that the temperature monitoring system always works normally and will not be interrupted due to system failures, thereby improving the safety and reliability of the entire switchgear operation.

Characteristics of Wireless Method in Temperature Monitoring of Switchgear

(1) Installation and power supply advantages

Installation convenience: Wireless temperature sensors can be directly installed on monitored parts such as high-voltage contacts, without the need for complex wiring. In the case of limited space and complex structure inside the switchgear, this installation method will not affect the original structure of the switchgear, nor will it interfere with the normal operation of other equipment. Per esempio, wireless temperature sensors can be conveniently installed in various switchgear such as central cabinets, handcart cabinets, fixed cabinets, and ring main units to monitor the temperature of contact/cable overlap heads.

Solving the problem of power supply: The system using passive wireless sensing technology, such as surface acoustic wave resonators to achieve passive temperature detection, solves the problem of sensor power supply. The problems of short battery life and difficulty in replacement, as well as difficulty in controlling the current size and installation of mutual inductance energy harvesting, have been improved in traditional active wireless temperature measurement methods where sensor probes and wireless transmission circuits are powered by batteries or small current transformers. Per esempio, in some switchgear application scenarios where frequent maintenance is difficult or battery replacement is inconvenient, passive wireless temperature measurement methods have great advantages19.

(2) Electrical Insulation and Safety

Good electrical insulation: The wireless working mode physically isolates the high-voltage side from the low-voltage side, avoiding insulation risks that may arise from electrical connections. In switchgear, due to the presence of high voltage, good insulation is crucial for the safe operation of temperature monitoring devices. Wireless temperature measurement can effectively prevent equipment failures and safety accidents caused by insulation problems.

High safety of equipotential measurement: The wireless temperature control device for switchgear has the characteristics of low power consumption and equipotential measurement. Equipotential measurement can reduce potential safety hazards caused by potential differences, ensure that temperature monitoring during the operation of the switchgear does not affect the electrical safety performance of the switchgear, and also ensure the safety of measurement personnel during maintenance and repair work.

(3) Data transmission and monitoring function

Wireless data transmission facilitates networking: temperature data is transmitted through wireless communication without the need for laying a large number of cables or optical cables. This method makes data transmission more flexible, facilitates networking, and enables centralized monitoring of multiple switchgear or monitoring points. Per esempio, when there are numerous switchgear in a large substation that require temperature monitoring, a wireless temperature measurement network can be easily constructed to transmit temperature data from each switchgear to the monitoring center 20.

Feature rich monitoring platform: The monitoring platform of the wireless temperature measurement system has multiple functions, such as data display, analisi, allarme, and so on. It can display temperature data in real-time, support historical curve calling, and administrators can adjust temperature alarm customization settings through permissions. The system also has fault display and database functions for storing temperature values for historical queries. Per esempio, data can be recorded every 5 verbale, which can save 24 months of historical data, making it convenient for operation and maintenance personnel to grasp the on-site temperature situation at any time and carry out corresponding processing.

(4) Measurement accuracy and response speed

Elevata precisione di misurazione: The wireless temperature measurement system adopts imported high-precision digital temperature sensors, and the measurement accuracy can reach ± 1 °C. Being able to accurately measure the temperature of the monitored parts inside the switchgear provides reliable temperature data basis for judging the operating status of the equipment, which helps to detect temperature anomalies in a timely manner, such as overheating of contacts and temperature rise of cable joints.

Fast response speed: It can quickly collect and transmit temperature data, ensuring timely and accurate data recording and analysis. This is very important for equipment such as switchgear that requires timely detection of temperature anomalies to avoid malfunctions. Per esempio, when a short circuit or overload occurs inside the switchgear, causing a sharp rise in temperature, the wireless temperature measurement system can quickly feedback the temperature changes to the monitoring system in order to take corresponding measures.

Characteristics of Infrared in Temperature Monitoring of Switchgear

(1) Non contact measurement

Does not affect equipment operation: Infrared temperature measurement determines its temperature by receiving infrared radiation signals from electrical contacts. This non-contact measurement method can detect temperature without stopping the equipment when monitoring electrical equipment. For equipment such as switchgear that cannot be easily powered off for testing, it is very suitable. Temperature monitoring of internal contacts, busbars, and other parts can be carried out without affecting the normal power supply of the switchgear, ensuring the continuous operation of the power system.

Reduce the risk of equipment damage: As there is no need for direct contact with the monitored equipment, it avoids potential damage to the equipment during the contact process, such as scratches, short circuits, and other risks. Allo stesso tempo, it also reduces the potential safety hazards caused by contact measurement, such as non-contact measurement being safer and more reliable in high voltage and high current environments inside switchgear.

(2) Limitations of Measurement

Easy to be affected by obstruction: The infrared probe temperature measurement method is easily affected by the obstruction of the infrared radiation path by the internal components of the switchgear, which cannot accurately measure the contact temperature and is not suitable for online temperature measurement of power distribution equipment. The internal structure of the switchgear is complex, with numerous components, circuits, and so on., which may block the propagation path of infrared radiation, resulting in inaccurate measurement results. Per esempio, in some compact switchgear, components such as busbars and isolation switches may block the infrared radiation emitted by the contacts, making it impossible for the infrared temperature probe to receive accurate infrared signals and accurately measure the temperature of the contacts.

Weak penetration ability and high environmental impact: The penetration ability of infrared radiation is not very strong, especially when encountering hard objects or thick iron sheets, its ability is greatly reduced. Inoltre, infrared radiation is highly dependent on the external environment, and different environments will also affect the accuracy of temperature information transmission. In the switchgear, if there are insulation heat shrink seals, metal shielding covers, and so on., it will seriously affect the penetration of infrared radiation, thereby affecting the accuracy of temperature measurement. Inoltre, factors such as environmental temperature, umidità, and dust can also interfere with the results of infrared temperature measurement. Per esempio, in humid or dusty environments, the propagation of infrared radiation can be affected, leading to increased measurement errors.

Sensore di temperatura in fibra ottica, Sistema di monitoraggio intelligente, Produttore distribuito di fibre ottiche in Cina

|

|

|

Sensori di temperatura a fibra ottica INNO ,sistemi di monitoraggio della temperatura.

Sensori di temperatura a fibra ottica INNO ,sistemi di monitoraggio della temperatura.