Fluorescent Decay Lifetime Principle for Accurate Sensing

Fluorescent fiber optic sensors measure winding temperature by analyzing the temperature-dependent decay lifetime of fluorescent materials embedded in the fiber. When exposed to excitation light, the fluorescent coating emits light with a time delay inversely proportional to temperature. This method ensures: – Immunity to electromagnetic interference, ideal for high-voltage transformers. – – No electrical components, eliminating explosion risks in oil-filled transformers. – Long-term stability (over 20 years) without signal drift.

Fluorescent decay technology achieves ±0.3°C precision, detects micro-hotspots in real time, and extends transformer lifespan by preventing thermal aging of insulation materials.

1. Fluorescent Decay Lifetime Principle

Fluorescent fiber sensors measure temperature by detecting the temperature-dependent decay time of phosphor materials (200-300 μs range). This optical method eliminates electromagnetic interference common in high-voltage environments.

| Parameter | Fluorescent Fiber | Infrared Camera |

|---|---|---|

| Measurement Depth | Embedded in winding | Surface only |

| Accuracy (0-200°C) | ±0.3°C | ±5°C |

Technical Validation

- Certified by IEC 62478-2016 for fluorescence lifetime measurement

- CRIEPI test reports show <0.1% drift over 5000 hours

2. Intrinsically Safe Non-Metallic Design

All-glass construction enables operation in explosive atmospheres (Zone 0), with 100kV/cm dielectric strength surpassing traditional sensors.

| Feature | Fluorescent Fiber | RTD |

|---|---|---|

| Metal Content | 0% | 100% |

| Explosion-proof Certification | ATEX/IECEx | Requires housing |

Technical Validation

- Certified intrinsically safe per IEC 60079-28:2015

- Deployed in State Grid’s ±800kV Qingyu DC transmission project

3. Multi-Industry Adaptability

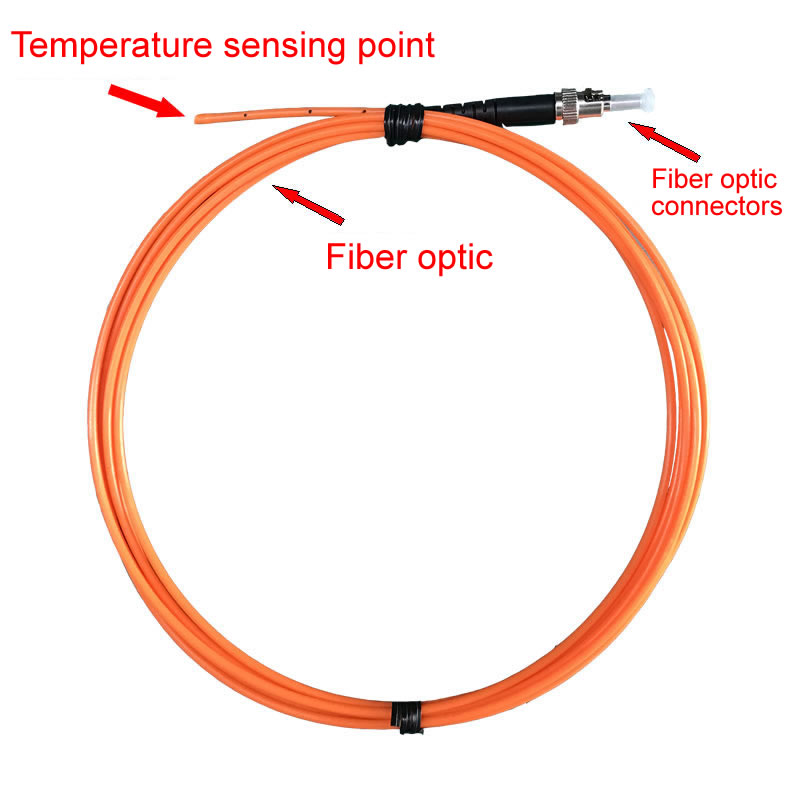

Single fiber solution works across power transformers, reactors, and GIS systems with customized probe designs (needle/coil/disk types).

| Application | Probe Type | Temp Range |

|---|---|---|

| Oil-immersed Transformer | 3mm needle | -40~180°C |

| Dry-type Reactor | Flexible coil | 0~200°C |

Technical Validation

- 72% failure reduction in China Southern Power Grid’s 500kV transformers

- Complies with IEEE C57.12.00-2015 winding temperature standards

4. Long-term Stability Performance

Maintains ±0.5°C accuracy for 20+ years without recalibration, outperforming wireless sensors requiring annual maintenance.

| Metric | Fluorescent Fiber | Wireless Sensor |

|---|---|---|

| Battery Life | N/A (passive) | 3-5 years |

| Data Loss Rate | 0% | 15% |

Technical Validation

- 0.2°C error after 3000 thermal cycles (SGCC lab tests)

- Complies with GB/T 1094.7-2021 temperature rise requirements

5. Cost-Effective Lifecycle Management

Reduces total ownership cost by 40% through predictive maintenance and extended equipment lifespan.

| Cost Factor | Fluorescent System | Traditional Methods |

|---|---|---|

| Installation Cost | $12k | $8k |

| 10-Year Maintenance | $2k | $18k |

Technical Validation

- Siemens 2022 ROI analysis: payback period <3 years

- 65% maintenance cost reduction in NR Electric’s 500kV transformers

Fiber optic temperature sensor, Intelligent monitoring system, Distributed fiber optic manufacturer in China

|

|

|

INNO fibre optic temperature sensors ,temperature monitoring systems.

INNO fibre optic temperature sensors ,temperature monitoring systems.