Why do reactors need to use fluorescent fiber optic temperature measurement systems

When the reactor sends abnormal or faulty signals, the faulty area of the reactor heats up and the temperature rises. By monitoring the temperature, the operating status of the reactor can be determined, thereby achieving the goal of protecting the reactor. General temperature measurement devices cannot measure the internal temperature of reactors. To solve this problem, FJINNO’s fluorescent fiber optic temperature measurement system can solve it through its anti-interference and high-temperature and high-pressure resistance characteristics.

Introduction to Fiber Optic Temperature Measurement System for Reactors

The IF-DK series reactor optical fiber temperature measurement adopts a fluorescent optical fiber temperature measurement device. The sensing probe of this device is made of non-metallic material and quartz optical fiber, which has complete electrical insulation and is not affected by high voltage and strong electromagnetic fields. It is resistant to chemical corrosion and pollution, and has fast response speed, simple installation, and high temperature resistance. The backend software is used for real-time online monitoring. Tsarin ya ƙunshi sassa uku: a fluorescent fiber optic Mai tsaron lafiyar zafin jiki, mai kyalli fiber optic bincike, da software na sadarwa na fiber optic.

| basic function (Conventional D-type) |

1. Three winding temperature measurement; Automatic/manual start/stop of cooling fan; Temperature display value compensation function for each channel 2. Samar da aikin akwatin baki, which can record the temperature data of the last power outage and the highest historical temperature; 3. Digital tube display; 4. Samar da madaidaicin kofa gidan wuta aikin ƙararrawa; 5. Bayar 1 set of over temperature alarm contacts (1 normally open, 1 normally closed); 6. Bayar 1 set of over temperature trip contacts (1 normally open, 1 normally closed); 7. Bayar 1 set of fan remote transmission contacts (1 normally open, 1 normally closed); 8. Bayar 1 set of temperature controller fault alarm contacts (1 normally open, 1 normally closed); |

| Customized features (Customizable for special needs) |

1. Bayar 1 iron core temperature measurement and 2 iron core over temperature alarm contacts (1 normally open, 1 normally closed) (Ina aiki); 2. Samar da aikin sadarwa na RS485, communication with time markers, capable of receiving time synchronization, MODBUS-RTU protocol (F aiki); 3. Ayyukan gano kuskuren fan da samar da lambobin ƙararrawa laifin fan (L aiki); 4. Bayar 4 masu zaman kansu 4-20mA ayyukan fitarwa na yanzu analog (E aiki); 5. Provide temperature measurement and control for the entire computer room environment; (G function) 6. Aiki na ƙararrawa don jujjuya yanayin hawan zafin jiki da ƙimar hauhawar zafin zafin ƙarfe; 7. Ka'idar sadarwa na iya ɗaukar hanyoyi kamar Profibus, Saukewa: IEC60870-5-103, Sadarwar Ethernet, da dai sauransu; |

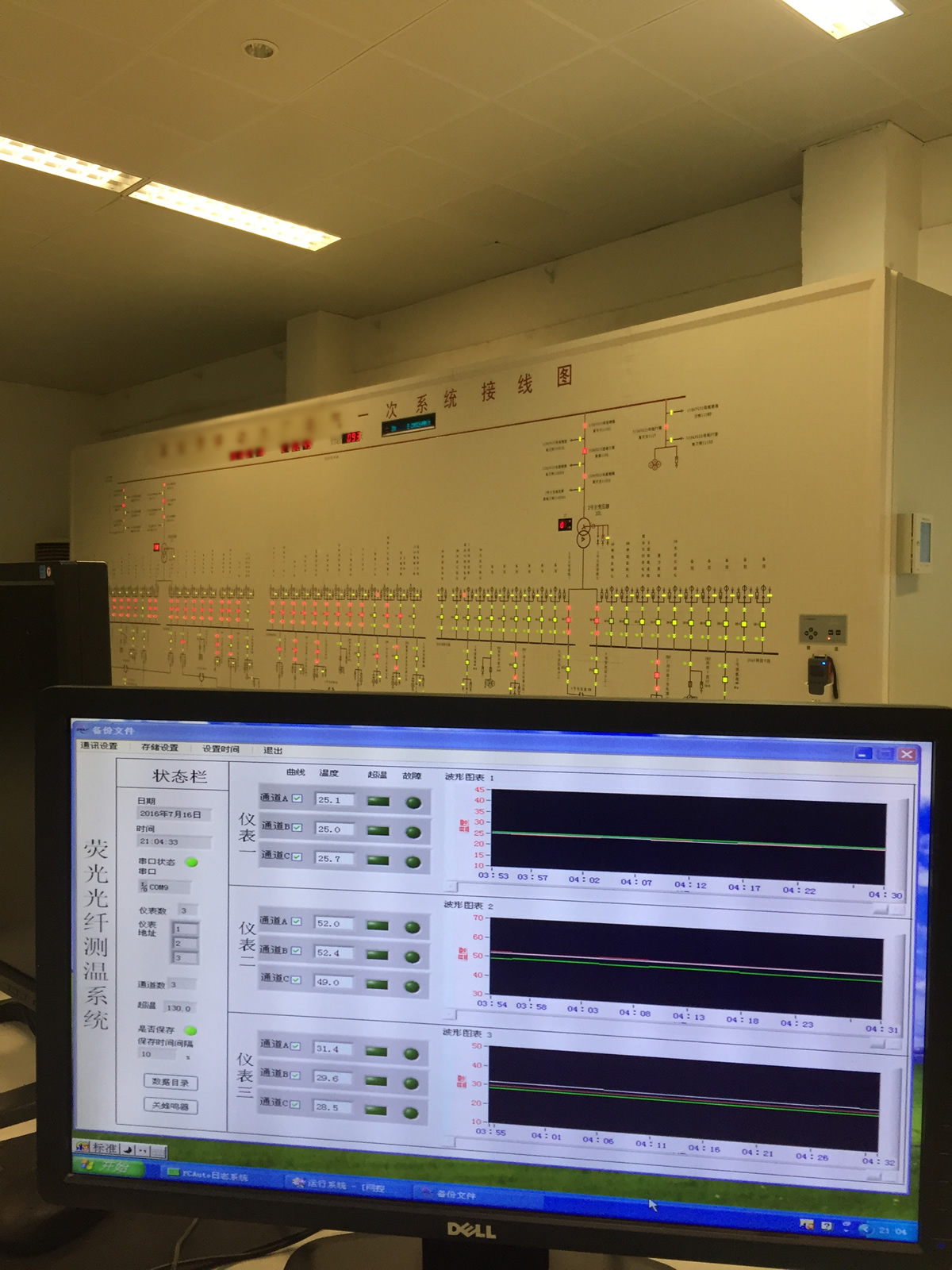

On site case study of fluorescence fiber optic temperature measurement device

|

|

INNO fiber optic na'urori masu auna zafin jiki ,tsarin kula da yanayin zafi.

INNO fiber optic na'urori masu auna zafin jiki ,tsarin kula da yanayin zafi.