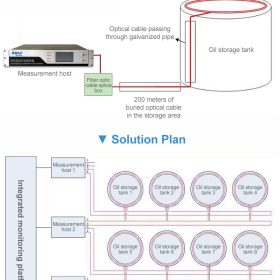

China’s chemical storage tanks mainly use floating roof tanks and spherical tanks. The top of the floating roof oil tank adopts secondary sealing technology, but it is not completely sealed, and there is a possibility of a small amount of chemical liquid and gas leaking out of the sealing ring. These leaked gases are prone to fire under natural conditions such as high temperature in the sun and lightning strikes. The detection of fires is particularly important. Due to the outdoor location, large volume, and wide tank area of storage tanks, linear fire detectors are commonly used.

Advantages of Veisoliyaka na Fiber Optic Temperature Measurement System for Oil Storage Tanks

(1) Sensors and optical cables not only serve as temperature detectors but also play an important role in signal transmission, integrating transmission and sensing. As there is no need to install additional sensing components, there is no fusion point in the middle of the sensing optical cable, resulting in high reliability.

(2) Continuous distributed measurement without measurement blind spots: DTS belongs to continuous distributed measurement and can obtain the temperature of each point along the sensing optical cable. Currently, the distance interval between adjacent temperature points can reach up to 0.25m, with rich temperature information and no measurement self zone. Kena ikuri, based on continuous temperature analysis, regional temperature difference alarm can be achieved.

(3) Low workload for later operation and maintenance: DTS’s sensing optical cables are designed based on outdoor communication optical cables, and the service life of communication optical cables can reach up to 30 veiyabaki; The core components of the DIS measurement host, such as light sources and splitters, are all communication grade devices with a designed lifespan of 100000 auwa (more than 10 veiyabaki). The host is equipped with a temperature calibration unit and a fault self check module, ensuring stable and reliable temperature measurement.

Software functions of distributed fiber optic temperature measurement system for oil storage tanks

Yavutaki ena ivakarau ni veisoliyaki ni taqe waiwai kei na veika e gadrevi me baleta na kena dikevi na katakata, a “dua na taqe, dua na misini” mode is adopted for design. Ena gauna vata oqori, me vakalevutaki na tudei ni ivakarau, e vakacurumi na ilavo katakata ni misini, ka na rawa ni veisau ga kevaka e sega na kena leqa na ivakarau. The fiber optic distributed temperature monitoring system monitors the required oil tanks in real-time online.

1) E dau dikeva na taqe yadua e dua na kakana e sega ni vakaiyauyau, ka vakacurumi ena veleti ni taqe kei na bati ni ikarua ni mama ni veivauci.

2) The anti-static optical fiber led out by the fiber optic temperature sensor installed on the floating plate inside the tank is protected by laying an explosion-proof metal hose inside the tank. The upper end of the explosion-proof metal hose is fixed on the flange plate of the manhole on the tank top, kei na mua e ra ni wai kaukamea e vakadaberi ena veleti e ciri ena loma ni taqe. Na iwalewale ni vakavinakataki e sega ni cakacaka katakata, kei na wai kaukamea ivakadinadina ni kacabote e semati vakavinaka ki na yago ni taqe.

3) Vakasamataka na veisau ena dua tale na ka ena dela ni taqe ni taqe e delavuvu, me rawa ni tarovi na kaukauwa ni optical ni lako curuma na wai kaukamea ivakadinadina ni kacabote mai na cakacaka e sega ni cakacaka rawa ena vuku ni kena dreti, na balavu maroroi me kakua ni lailai mai na 0.5 vaka na cere ni lalaga e tautuba ni taqe, kei na dua na misini ni waqa ni optical e dodonu me vakayagataki me lewai kina na kakana tudei ni optical ena dua na vanua ni itutu.

4) The anti-static optical fiber led out by the fiber optic temperature sensor installed on the floating plate inside the tank is laid with explosion-proof galvanized pipes outside the tank and led along the escalator or tank wall to the existing cable tray on the ground. It is connected and protected with the communication optical cable installed inside the cable tray through a waterproof optical cable splice box, and the elbow part is connected with explosion-proof metal hoses.

5) Na sensor kece ni katakata ni fiber optic e vakacurumi ena delavuvu ni taqe ni waiwai yadua ena vanua ni taqe era na kau yani ena kaukauwa ni optical ka converged ki na keveli ni veitaratara ni sikinala kei na vakau ki na rumu ni vakadikeva. Na keveli ni veitaratara e vakadavori vakadodonu, kei na iduruduruniliga e semati ki na ose kaukamea ivakadinadina ni kacabote.

6) Ni sa vakau na keveli ni veitaratara ni mata mai na vanua ni taqe ki na rumu ni vakadikevi ni iyaya, e semati ki na sala ni vakadikevi ni iyaya ni kilai ka tautauvata kei na DTS e vakayacora e dua na buina ni fiber optic vakayawa vata kei na dua na isema ni kakana optic, ka sa dua na kaukauwa ni lade mata.

7) A multi-channel DTS distributed fiber optic temperature measurement host is placed in the monitoring room to achieve temperature signal acquisition, ivakasala ni tubu ni katakata, sivia na alamu ni katakata, kunei ni cala, kei na veiqaravi ni itukutuku me baleta na sensors ni katakata ni fiber optic ka vakacurumi ena vanua ni taqe ni waiwai. It can be connected to the fire alarm control system through the switch alarm interface to achieve fire alarm and display it in the fire duty room. Na yavunilewa ni katakata ni gauna oqo, ituvaki ni alamu, kei na ivakarau ni katakata ni ivakarau ni katakata kece sara ni vanua ni maroroi iyaya e rawa ni vakaraitaki ena rumu ni cakacaka ena mape vakalivaliva ni configuration software. An external sound and light alarm can also be connected to the instrument operation room to provide alarm signals.

INNO fiber optic sensors ,ivakarau ni vakadikevi ni ivakarau ni ivakarau.

INNO fiber optic sensors ,ivakarau ni vakadikevi ni ivakarau ni ivakarau.