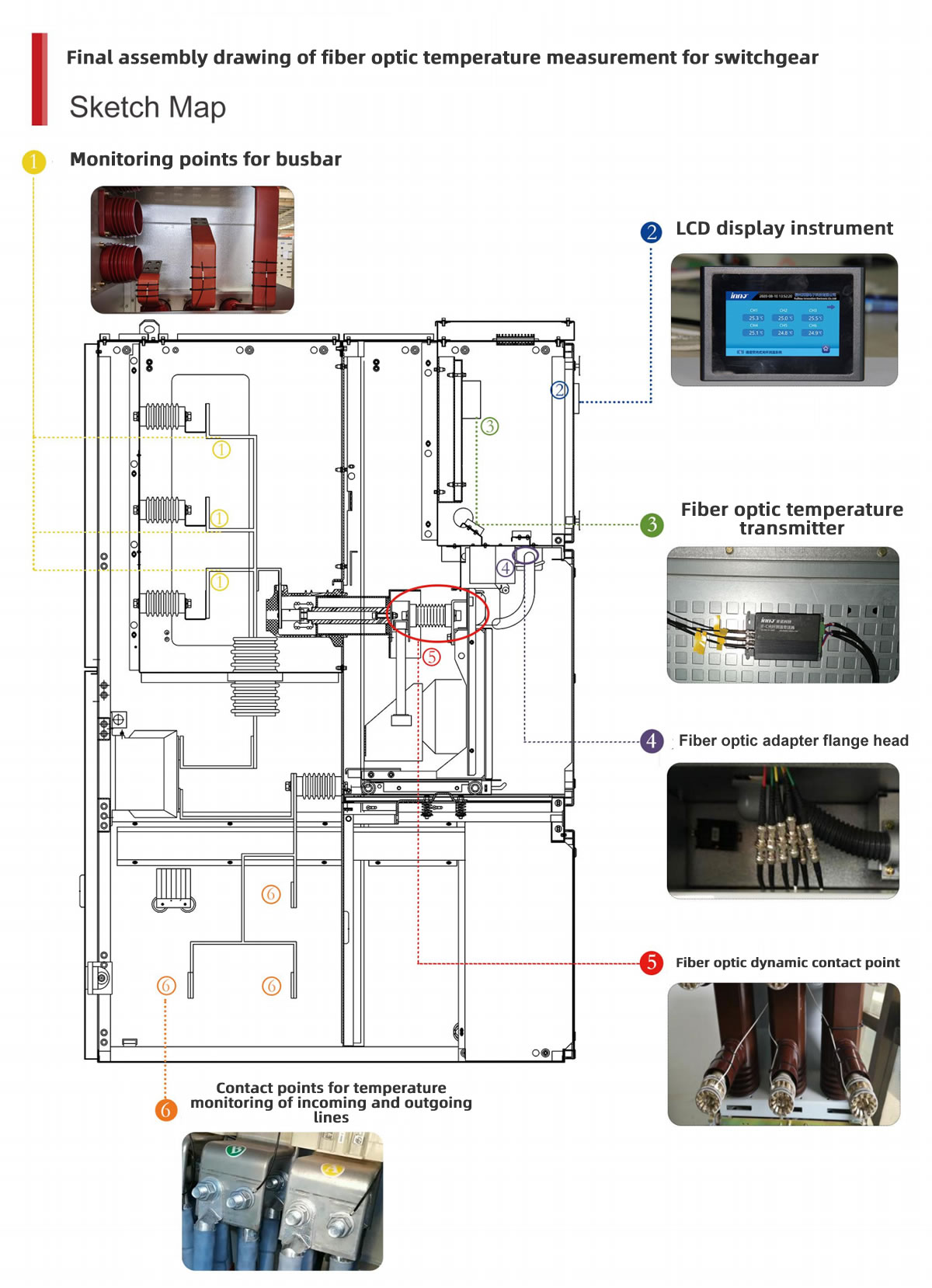

The point type fiber optic online temperature measurement system for switchgear adopts a Zuntz optiko fluoreszentearen tenperatura sentsore that can monitor the hot spot temperature inside the switchgear in real time. It can monitor the operating temperature of electrical equipment, especially the temperature of easily heated positions such as switchgear contacts, busbars, and electrical contacts. The fiber optic temperature measurement system is an important means of temperature rise warning and prevention of switchgear failure accidents caused by temperature rise. This allows switchgear temperature inspectors to detect the heating of equipment joints in the switchgear in advance, preventing more serious fires or power outages.

The temperature measurement system of the switchgear includes:

1. Zuntz optikoko tenperatura sentsorea;

2. Fiber optic temperature measurement transmitter;

3. LCD display instrument (aukerakoa);

4. Fiber optic temperature measurement system software (aukerakoa);

5. Other accessories.

Our company has actual application cases of high-voltage switchgear monitoring systems, which can be directly put into use.

The fiber optic temperature measurement system adopts internationally advanced fluorescent fiber optic temperature sensing technology, which has the advantages of high voltage resistance, no electromagnetic interference, intrinsic safety, long-term reliability, and easy expansion. It can monitor the temperature of monitoring points such as generators, high-voltage switchgear, ring main cabinets, outdoor and underground cable joints in the power generation and supply system in real-time online.

Function of fiber optic temperature measurement system for switchgear

1. It can continuously monitor the temperature information of easily hot spots such as switchgear contacts, circuit breakers, busbars, and incoming and outgoing lines in real-time.

2. Using various diagnostic methods to analyze the health status of equipment, including all device parameter limit exceeding alarms, analysis, and other judgment methods.

3. Provide sound and light alarms, dry contact output, human-machine interface display of alarm information, etab.

4. Provide an upper computer software system to display real-time information on various contacts of the current switchgear, as well as historical data on temperature information of each contact in the past month.

INNO zuntz optikoko tenperatura sentsoreak ,tenperatura kontrolatzeko sistemak.

INNO zuntz optikoko tenperatura sentsoreak ,tenperatura kontrolatzeko sistemak.