Why do reactors need temperature measurement? Sistema de medición de temperatura de fibra óptica para reactor

Reactors are the main auxiliary equipment of long-distance transmission systems, playing an important role in power transmission due to their superior electrical performance. During the operation of a reactor, it is often due to external factors, internal structure, and other factors that the reactor may experience local temperature rise and overheating, ultimately leading to local burnout or even scrapping. This brings significant economic losses to the country and enterprises. Por lo tanto, adopting a reactor sistema de medición de temperatura de fibra óptica and real-time monitoring of the internal temperature of the reactor is of great significance and practical value.

The reactor fiber optic temperature measurement adopts a fluorescent fiber optic temperature measurement device. The sensing probe of this device is made of imported quartz fiber, which has complete electrical insulation and is not affected by high voltage and strong electromagnetic fields. It is resistant to chemical corrosion and pollution, and has fast response speed, Instalación sencilla, and high temperature resistance. The backend software is used for real-time online monitoring.

Purpose of Reactor Fiber Optic Temperature Measurement System

When the reactor sends abnormal or faulty signals, the faulty area of the reactor heats up and the temperature rises. By monitoring the temperature, the operating status of the reactor can be determined, thereby achieving the goal of protecting the reactor.

Ordinary temperature measurement devices cannot measure the internal temperature of reactors. To solve this problem, our company’s developed sistema de medición de temperatura de fibra óptica fluorescente can solve this problem through its anti-interference and high-temperature and high-pressure resistance characteristics.

Design principles of fiber optic temperature measurement host for reactors

Principio de practicidad

La construcción del sistema se adhiere al principio de practicidad. Sobre la base de la practicidad, Se tiene en cuenta la progresividad y la previsión, y estándar, Se seleccionan productos y plataformas de desarrollo avanzados y maduros para construir un sistema que sea práctico y resuelva problemas prácticos.

Principio de normalización

Business applications have the characteristics of complex business, numerous processes, large amount of information, and multiple application levels. Through unified application function planning, consensus can be reached on business operations at the application level, guiding various business units to carry out business with unified standards.

The system software and hardware platforms and application development tools used in the construction of business applications should comply with national standards, del Ministerio de la Industria de la Información, Especificaciones técnicas y requisitos pertinentes de la empresa.

El principio de uniformidad

Siguiendo la política de gestión centralizada de la información, Planificación general, Diseño general, y la implementación paso a paso, El proceso de implementación incorpora cuatro principios unificados: Liderazgo unificado, Planificación unificada, Estándares unificados, y organización e implementación unificadas.

Principio de fiabilidad

The software and hardware resources need to ensure the uninterrupted and reliable operation of the cable temperature measurement system for 7 × 24 horas. Por lo tanto, it is necessary to equip a complete design of reliability measures to ensure the high reliability of system operation and fully consider the reliability requirements of key system applications.

Mecanismo de seguridad fiable

Este sistema adopta una serie de medidas de encriptación segura, con un 64 Algoritmo de cifrado de bits. El sistema tiene una mayor seguridad y puede prevenir eficazmente la fuga y el robo de datos, Garantizar la seguridad, exactitud, y la integridad de los datos del sistema, y la prevención de las operaciones ilegales de los operadores y de las operaciones ilegales de los operadores legítimos. A system may be used by multiple operators, and to ensure system security, hierarchical permission management is implemented. The system administrator authorizes operators with different usage permissions, and each operator can only perform various operations within the scope of permissions, resulting in higher system security.

La interfaz de operación es simple, amistoso, y altamente inteligente

The system provides most of the default data required during operation, and each operation conforms to the actual business workflow, avoiding repetitive operations by operators. El sistema verifica automáticamente la legalidad de los datos de entrada y proporciona avisos amigables para los errores del operador.

Reasonable system structure design, high degree of abstraction of program functional modules

It can be flexibly configured according to the changes in the actual situation of users and the various needs of different users, to maximize the satisfaction of user needs. There are various rate management and multi type table management functions for users to better use this system.

The system adopts a Web Service platform and a B/S architecture design, which is in line with the trend of application development.

Stable operation, reliable data, actual operation of thousands of systems, and over 200 new projects added each year.

La plataforma es fácil de operar, Fácil de dominar, y el proceso de instalación es sencillo. Los datos se pueden generar automáticamente en varios informes según sea necesario, Mejora de la eficiencia de la gestión.

Introduction to the installation of temperature measurement wiring for reactors

1.1 Marco estructural

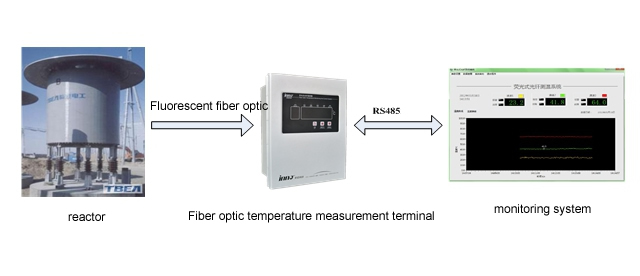

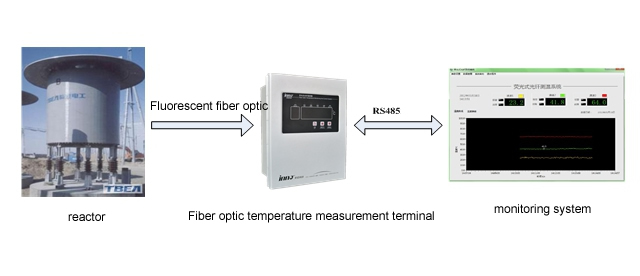

El sistema consta de tres partes: a fluorescent fiber optic controlador de temperatura, una sonda fluorescente de fibra óptica, y software de comunicación por fibra óptica.

Reactor temperature measurement

La transmisión de datos entre el sistema backend y el terminal de medición de temperatura adopta el método de comunicación RS485. Toda la recopilación de datos, Administración, y la visualización de la temperatura se completan con un software de comunicación, y el sistema realiza principalmente la recopilación de datos y el monitoreo de la medición de temperatura. El terminal de medición de temperatura de fibra óptica integra fibras ópticas fluorescentes multicanal, proporcionando comunicación RS485 externa, Anti-interferencia, y diseño resistente a la corrosión.

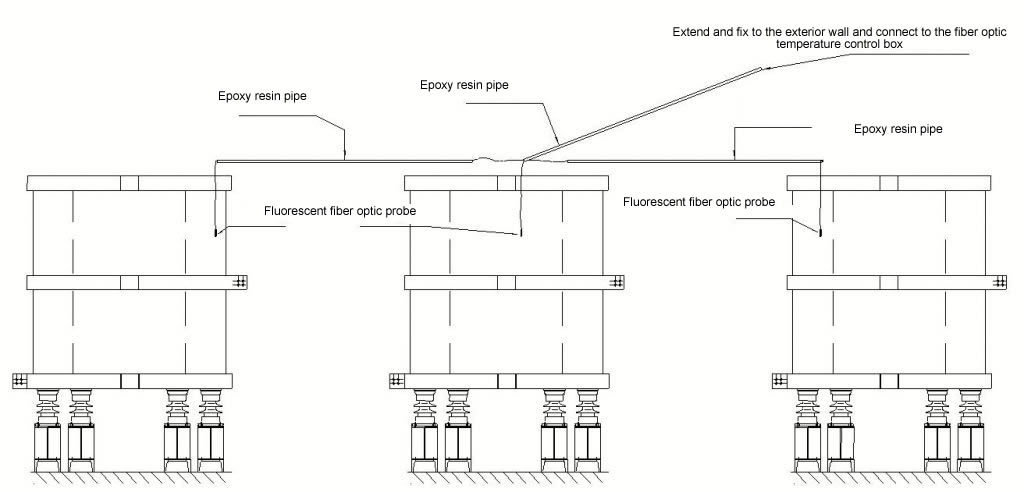

The fluorescent fiber optic temperature measurement terminal is embedded and installed in the box, and the outgoing fiber optic goes towards the upper part of the wall, which needs to exceed the height of the reactor. After passing through the epoxy resin pipe installed on the wall, the three fiber optic cables are combined and enter the B-phase reactor; The B-phase optical fiber is directly installed inside the inner airway wall of the reactor; Un. The two phases of C are respectively introduced into the A-phase and C-phase reactors through overhead insulated epoxy resin pipes, and installed in the inner air duct wall of the reactor.

Application functions of fluorescent fiber optic temperature measurement system

Real time monitoring of fluorescent fiber optic temperature measurement system

La densidad de recopilación de datos se puede configurar de acuerdo con las necesidades del cliente, y el sistema recopilará datos regularmente en función de los parámetros establecidos. Entonces, Se mostrará en forma de tabla o dibujo de curva para lograr un monitoreo en tiempo real. Monitoreo en tiempo real del estado de operación de los equipos; Monitorización y registro en tiempo real de la temperatura del reactor.

Basic functions of fluorescent fiber optic temperature measurement system

1) Consulta de datos de temperatura

Puede consultar los datos de temperatura para fechas especificadas, hojear, Impresión, y exportar a Excel.

2) Almacenamiento de datos históricos de temperatura

3) Registre permanentemente los datos de temperatura

Safety Design of Fluorescent Fiber Optic Temperature Measurement System

The security of the system is crucial, therefore, in the design of the main station system, the security of the system should be fully considered to prevent unauthorized intrusion and leakage of confidential information. From the perspective of main station system security protection, the system provides security protection in both communication channels and system data.

Data security of fluorescent fiber optic temperature measurement system

Equipped with three-level security mechanisms at the operating system level, database level, and application software level.

Operating system level: Set different permission passwords on the network, non system administrators cannot operate servers and databases, and ensure system security and relative independence through routing, firewall, and other settings.

Database level: Set up demanders with different permissions and corresponding passwords in the database to ensure that unauthorized demanders cannot use data, and different demanders cannot use data beyond their level.

Application software level: Provides strict user login verification, permission control, and comprehensive management of event logs and operation records. System permission control includes functional permission control and data access permission control.

Function permission control:

The functional permission control system manages permissions from three dimensions: control objects, object operations, and operators. Based on this, it provides authorization methods for control object groups, operation groups, and operator roles. The accuracy of permission control can be determined to specific control objects and operators. The system determines the operation permissions of the login personnel based on these three dimensions.

The control objects of the system include system level nodes, terminal devices, etc. Each control object has corresponding operations, and each authorization includes three parts: a control object group, an operation or operation group, and an operator role. In order to simplify and facilitate permission management, the system provides control object group permission inheritance.

The system provides a hierarchical authorization mechanism, which enables the system to have the ability of distributed permission management and solves the problem of overly complex permission management.

Data access permissions:

The data access permission control mechanism adopts the security audit mechanism provided by the database, providing data access user control, and providing log auditing for all data operations.

The original database only has query functionality, and the applications used only operate on the application database to ensure data security.

The system can store electricity consumption data with time markers and various analytical application calculation data, with a storage time of more than 2 años. Además, the system has a powerful backup subsystem.

Detailed operation log records are available for all manual intervention data. The system design ensures high fault tolerance, and the database has three levels of data validation: field level, record level, and database level, ensuring the storage of illegal data.

Introduction to Fiber Optic Temperature Measurement Equipment for Reactors

1.1 Características principales

The fluorescent fiber optic temperature controller is embedded installation. Este producto tiene ventajas técnicas únicas en la medición de temperatura en entornos especiales como el alto voltaje, Fuerte interferencia electromagnética, etc. The temperature hotspot and measurement signal receiving part of the sensor de temperatura fluorescente de fibra óptica do not use electrical connections, que puede funcionar con alta precisión y estabilidad durante mucho tiempo, mejorando en gran medida su rango de aplicación. Al mismo tiempo, the fiber optic temperature controller effectively eliminates the hidden dangers of local temperature rise and overheating that may occur during the operation of the reactor, ultimately leading to the burnout and scrapping of the reactor, which is not conducive to the safe operation of the reactor. El controlador de temperatura de fibra óptica tiene alta precisión y sensibilidad, es resistente a la alta presión y se puede monitorear de forma remota, tiene una larga vida útil, es de tamaño pequeño, hace que el mantenimiento del instrumento sea simple y conveniente, y garantiza un transporte seguro. Its internal modular integrated design is aesthetically pleasing and reasonable.

1.2 Funciones principales

Can install an integrated multi-channel fluorescent fiber optic temperature measurement and demodulation instrument;

LED digital tube touring display of reactor hot spot temperature;

Provide RS485 communication interface to connect with upper computer instruments and provide temperature acquisition and transmission;

Fan start stop function, providing a pair of fan control output contacts (AC220V, 10Un);

Over temperature alarm function, over temperature trip function, temperature control fault alarm function, each providing a pair of normally open output dry contacts.

Sensor de temperatura de fibra óptica, Sistema de monitoreo inteligente, Fabricante de fibra óptica distribuida en China

|

|

|

Sensores de temperatura de fibra óptica INNO ,Sistemas de control de temperatura.

Sensores de temperatura de fibra óptica INNO ,Sistemas de control de temperatura.