El rango de medición especificado en el “Controlador electrónico de temperatura para transformadores” (JB/T7631-2016), que utiliza Pt100 como sensor de temperatura tradicional, solo se puede limitar a menos de 1000 V, y este sensor está hecho de material metálico, lo que supone un peligro para la seguridad. Por lo tanto, Las sondas y los cables del sensor de temperatura para medir la temperatura del devanado del transformador tienen requisitos más altos.

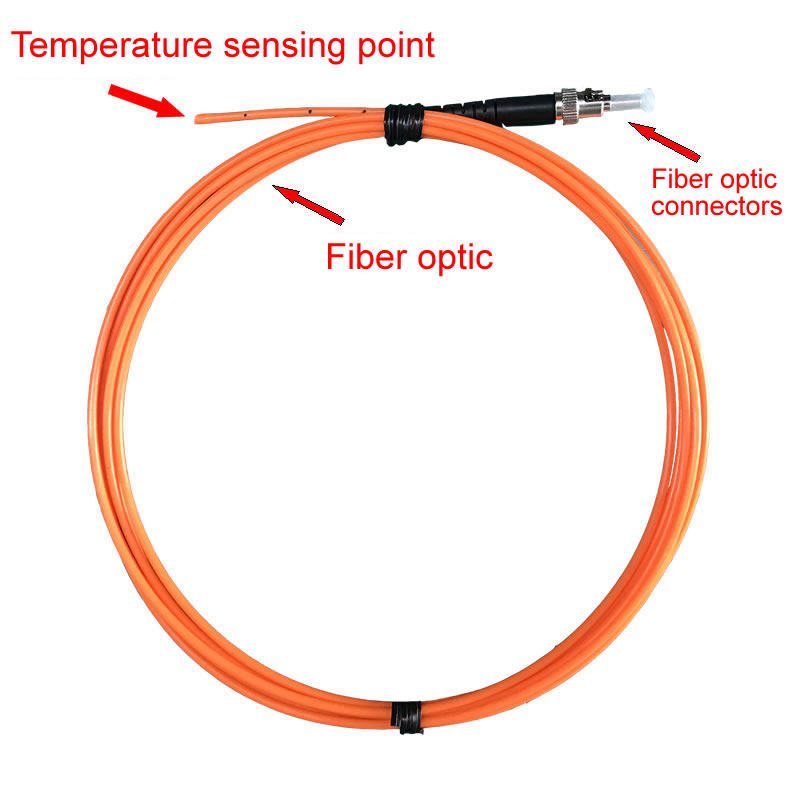

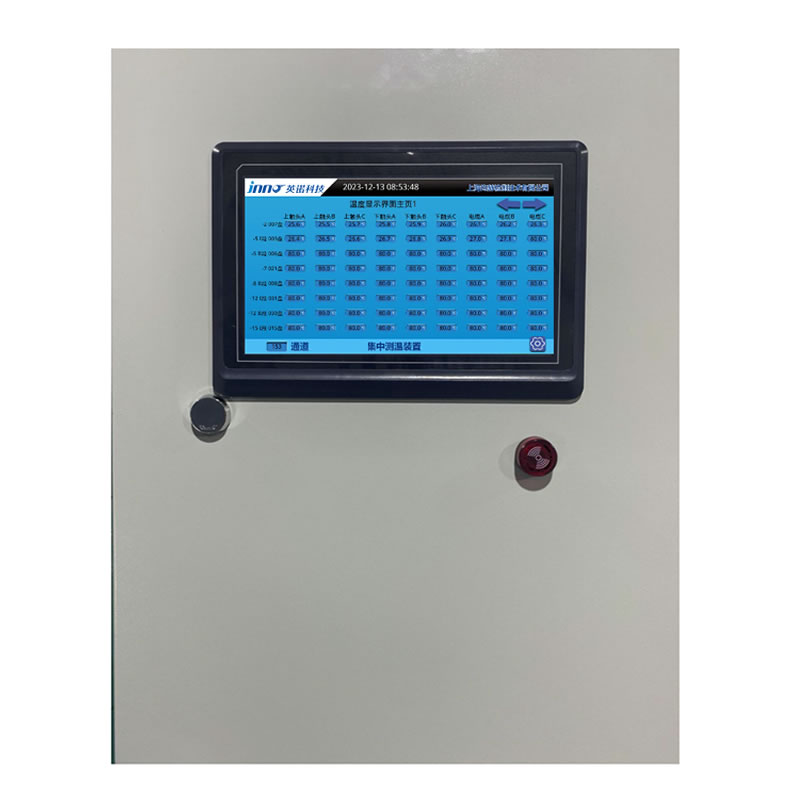

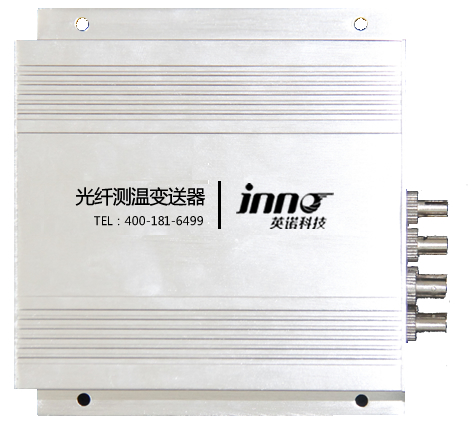

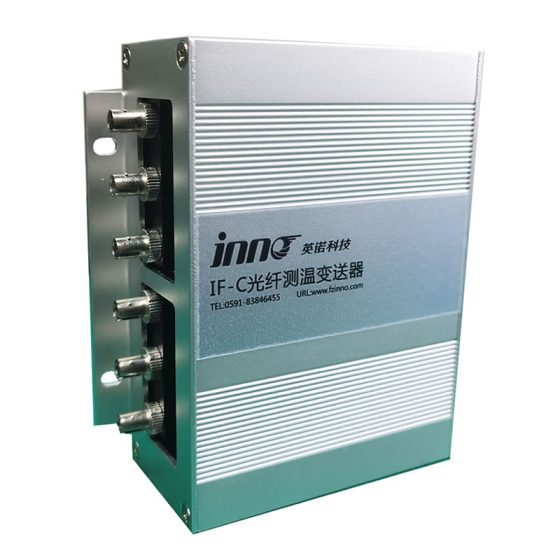

El sistema de medición de temperatura de fibra óptica para transformadores de tipo seco utiliza un sensor de temperatura fluorescente de fibra óptica desarrollado de forma independiente por Fuzhou INNO Technology como elemento sensor de temperatura. Este elemento sensor de temperatura es inmune a las interferencias electromagnéticas y resistente a la alta tensión (100Distancia entre KV/fibra y cable a tierra de 0,4 m). La medición de temperatura de fibra óptica fluorescente resuelve por completo los posibles riesgos de seguridad de la fuente de medición de temperatura y mejora el nivel de seguridad de los transformadores. El sistema de medición de temperatura de fibra óptica fluorescente para transformadores de tipo seco tiene como objetivo lograr el aislamiento y el blindaje de las señales de interferencia eléctrica externa en el entorno operativo de los transformadores de tipo seco, incluida la fuente de alimentación, Entrada de señal, Salida de señal, y carcasa de la caja de control de temperatura. Sin sustancias metálicas, Seguridad intrínseca. En respuesta a la vibración, polvo, humedad, aceite y otros entornos de trabajo in situ, Se toman medidas de protección multicapa para garantizar que la fibra óptica controlador de temperatura tiene buena compatibilidad electromagnética, Garantizar un funcionamiento estable y fiable.

Nuestra empresa tiene casos de aplicación reales de sistemas de medición de temperatura de fibra óptica para transformadores de tipo seco, que se puede poner en uso directamente.

La función de los fluorescentes Sensor de temperatura de fibra óptica para transformador seco

Monitoreo en tiempo real del devanado del transformador “punto caliente” temperatura

Estado de operación del transformador evaluable para mejorar la confiabilidad del sistema.

Monitoreo en tiempo real de la información de temperatura en el estado de operación del transformador

Puede controlar las cargas de forma oportuna y eficaz, Optimice la configuración de la operación de carga del transformador.

Monitoreo oportuno de la información de alarmas

Durante el funcionamiento de carga máxima, Puede prevenir fallas no planificadas y repentinas causadas por el sobrecalentamiento del transformador.

Monitoreo en línea a largo plazo de las tendencias de temperatura del transformador

Puede construir un archivo de tendencia de cambio de temperatura del transformador para lograr la gestión previa y la predicción de riesgos.

Proporcionar dinamismo, tiempo real, seguro, e información confiable

El sistema de enfriamiento se puede iniciar de manera oportuna para prolongar la vida útil del transformador.

| Función básica | 1. Medición de temperatura de tres devanados; Arranque/parada automático/manual del ventilador de refrigeración; Función de compensación del valor de visualización de la temperatura para cada canal

2. Proporcionar función de caja negra, que puede registrar los datos de temperatura del último corte de energía y la temperatura histórica más alta; 3. Pantalla digital de tubo; 4. Proporcione la función de alarma de apertura del punto de apertura del gabinete de la puerta del transformador; 5. Proporcionar 1 Conjunto de contactos de alarma de sobretemperatura (1 Normalmente abierto, 1 Normalmente cerrado); 6. Proporcionar 1 Conjunto de contactos de disparo por sobretemperatura (1 Normalmente abierto, 1 Normalmente cerrado); 7. Proporcionar 1 Conjunto de contactos de transmisión remota del ventilador (1 Normalmente abierto, 1 Normalmente cerrado); 8. Proporcionar 1 Conjunto de contactos de alarma de falla del controlador de temperatura (1 Normalmente abierto, 1 Normalmente cerrado); |

| Características personalizadas | 1. Proporcionar 1 medición de la temperatura del núcleo de hierro y 2 Contactos de alarma de sobretemperatura del núcleo de hierro (1 Normalmente abierto, 1 Normalmente cerrado) (Yo funciono);

2. Proporciona la función de comunicación RS485, Comunicación con marcadores de tiempo, Capaz de recibir sincronización horaria, Protocolo MODBUS-RTU (Función F); 3. Función de diagnóstico de fallas del ventilador y provisión de contactos de alarma de fallas del ventilador (Función L); 4. Proporcionar 4 Funciones de salida de corriente analógica independientes de 4-20 mA (Función E); 5. Proporciona medición y control de temperatura para todo el entorno de la sala de computadoras; (Función G) 6. Función de alarma para la tasa de aumento de la temperatura del devanado y la tasa de aumento de la temperatura del núcleo de hierro; 7. El protocolo de comunicación puede adoptar métodos como Profibus, IEC60870-5-103, Comunicación Ethernet, etc; |

Caso de instalación en el sitio del dispositivo de medición de temperatura de fibra óptica para el devanado de transformador de tipo seco

|

|

|

Las ventajas de los sensores de temperatura fluorescentes de fibra óptica

Los sensores de temperatura fluorescentes pertenecen a todos los dispositivos de medición óptica

Solo las señales ópticas sin señales eléctricas son verdaderas sondas pasivas.

Alta resistencia de aislamiento y voltaje

El sensor de temperatura fluorescente de fibra óptica puede soportar un voltaje de frecuencia de alimentación de 100 kV.

Las fibras ópticas fluorescentes son inherentemente inmunes a las interferencias electromagnéticas

La precisión de la detección y la estabilidad de la transmisión de datos no se ven afectadas en absoluto.

Fuerte capacidad de descarga eléctrica anticontaminación

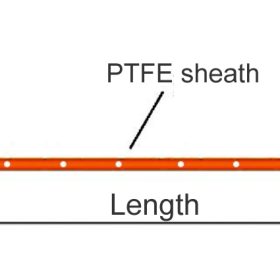

El sensor de fibra óptica fluorescente está cubierto con una cubierta con una fuerte resistencia a las manchas para garantizar la seguridad del sistema. Los materiales sensibles a la temperatura tienen una alta confiabilidad

El material de detección de temperatura del sensor de temperatura es material de tierras raras, que tiene una estabilidad a largo plazo y se ha aplicado con éxito en el monitoreo de equipos durante más de 30 años de vida útil. Medición precisa del posicionamiento

La sonda de detección de temperatura tiene un volumen pequeño y puede ubicar con precisión la posición de instalación.

El ciclo de medición de temperatura es menor que, con alto rendimiento en tiempo real

El ciclo de medición de temperatura es menor que 1 segundo, lo que puede garantizar plenamente la puntualidad de la alarma.

Sensores de temperatura de fibra óptica INNO ,Sistemas de control de temperatura.

Sensores de temperatura de fibra óptica INNO ,Sistemas de control de temperatura.

WhatsApp (en inglés)

Escanea el código QR para iniciar un chat de WhatsApp con nosotros.