Why do reactors need to use fluorescent fiber optic temperature measurement systems

When the reactor sends abnormal or faulty signals, the faulty area of the reactor heats up and the temperature rises. By monitoring the temperature, the operating status of the reactor can be determined, thereby achieving the goal of protecting the reactor. General temperature measurement devices cannot measure the internal temperature of reactors. To solve this problem, FJINNO’s sistema de medición de temperatura de fibra óptica fluorescente can solve it through its anti-interference and high-temperature and high-pressure resistance characteristics.

Introduction to Fiber Optic Temperature Measurement System for Reactors

The IF-DK series reactor optical fiber temperature measurement adopts a fluorescent optical fiber temperature measurement device. The sensing probe of this device is made of non-metallic material and quartz optical fiber, which has complete electrical insulation and is not affected by high voltage and strong electromagnetic fields. It is resistant to chemical corrosion and pollution, and has fast response speed, Instalación sencilla, and high temperature resistance. The backend software is used for real-time online monitoring. El sistema consta de tres partes: a fluorescent fiber optic controlador de temperatura, una sonda fluorescente de fibra óptica, y software de comunicación por fibra óptica.

| Función básica (Conventional D-type) |

1. Medición de temperatura de tres devanados; Arranque/parada automático/manual del ventilador de refrigeración; Función de compensación del valor de visualización de la temperatura para cada canal 2. Proporcionar función de caja negra, que puede registrar los datos de temperatura del último corte de energía y la temperatura histórica más alta; 3. Pantalla digital de tubo; 4. Proporcione la función de alarma de apertura del punto de apertura del gabinete de la puerta del transformador; 5. Proporcionar 1 Conjunto de contactos de alarma de sobretemperatura (1 Normalmente abierto, 1 Normalmente cerrado); 6. Proporcionar 1 Conjunto de contactos de disparo por sobretemperatura (1 Normalmente abierto, 1 Normalmente cerrado); 7. Proporcionar 1 Conjunto de contactos de transmisión remota del ventilador (1 Normalmente abierto, 1 Normalmente cerrado); 8. Proporcionar 1 Conjunto de contactos de alarma de falla del controlador de temperatura (1 Normalmente abierto, 1 Normalmente cerrado); |

| Características personalizadas (Customizable for special needs) |

1. Proporcionar 1 medición de la temperatura del núcleo de hierro y 2 Contactos de alarma de sobretemperatura del núcleo de hierro (1 Normalmente abierto, 1 Normalmente cerrado) (Yo funciono); 2. Proporciona la función de comunicación RS485, Comunicación con marcadores de tiempo, Capaz de recibir sincronización horaria, Protocolo MODBUS-RTU (Función F); 3. Función de diagnóstico de fallas del ventilador y provisión de contactos de alarma de fallas del ventilador (Función L); 4. Proporcionar 4 Funciones de salida de corriente analógica independientes de 4-20 mA (Función E); 5. Proporciona medición y control de temperatura para todo el entorno de la sala de computadoras; (Función G) 6. Función de alarma para la tasa de aumento de la temperatura del devanado y la tasa de aumento de la temperatura del núcleo de hierro; 7. El protocolo de comunicación puede adoptar métodos como Profibus, IEC60870-5-103, Comunicación Ethernet, etc; |

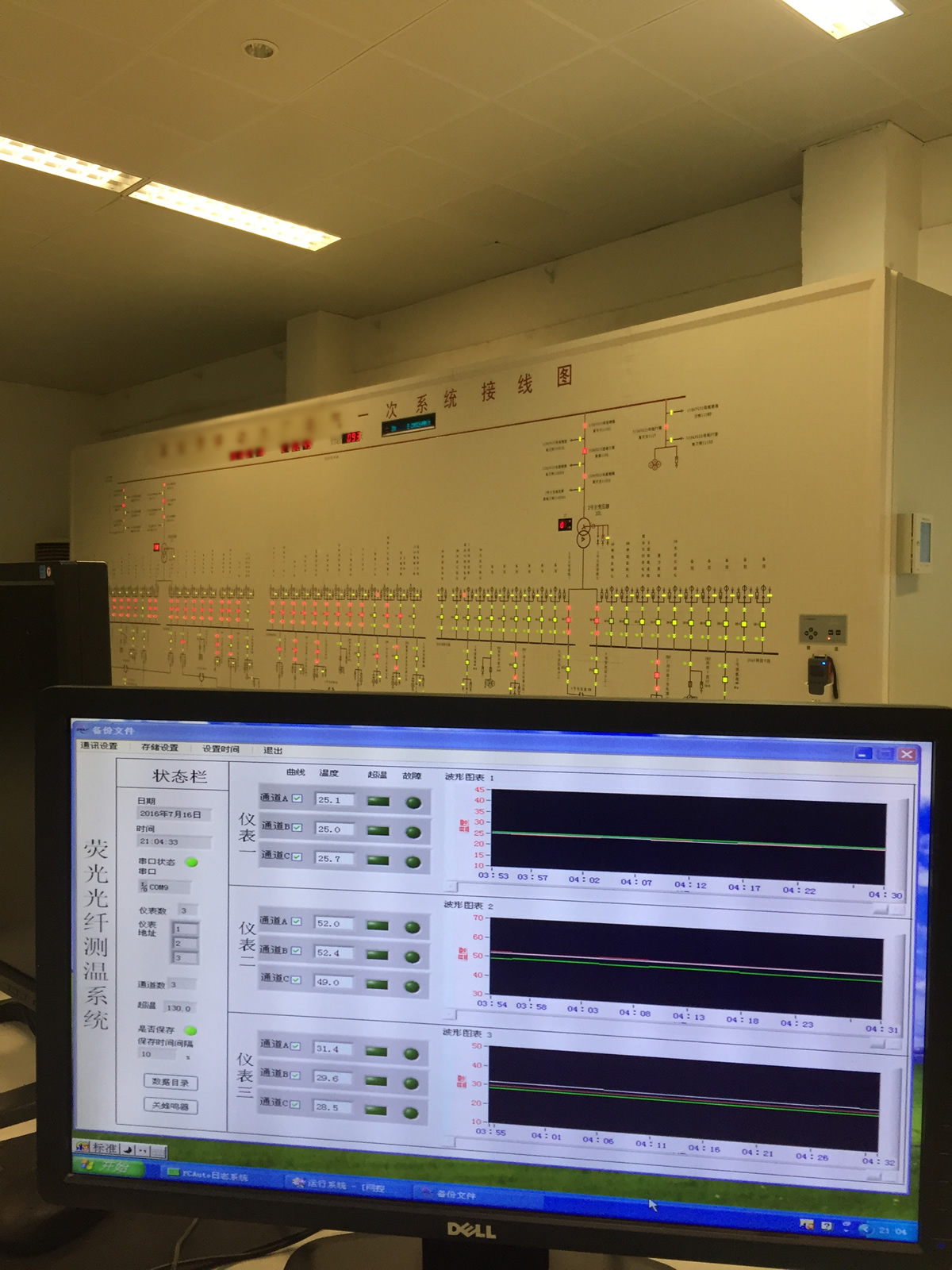

On site case study of fluorescence fiber optic temperature measurement device

|

|

Sensores de temperatura de fibra óptica INNO ,Sistemas de control de temperatura.

Sensores de temperatura de fibra óptica INNO ,Sistemas de control de temperatura.