PHM Transformer Intelligentes Online-Überwachungsgerät Systemfunktion

Im Stromversorgungssystem des städtischen Schienenverkehrs, Das Umspannwerk versorgt verschiedene elektrische Geräte des Kraftwerks mit Strom, einschließlich Umweltkontrollausrüstung, Kommunikationsgeräte, Umfassendes Monitoring, Wasserversorgungs- und Entwässerungssystem, Rolltreppen, etc. Seine Zuverlässigkeit hängt mit der Sicherheit und dem normalen Betrieb der Station zusammen. Gewährleistung des sicheren und zuverlässigen Betriebs von Transformatoren in Umspannwerken, Es ist notwendig, verschiedene Parameterindikatoren während des Betriebs des Transformators in Echtzeit zu erfassen, und bieten Frühwarnung und Fehlererkennung. Der traditionelle Betriebs- und Wartungsmodus erfordert häufig regelmäßige Inspektionen und Wartungen, was es schwierig macht, bestimmte versteckte Fehler rechtzeitig zu erkennen und zu beseitigen, erhöht das Risiko, dass während des Betriebs Fehler auftreten, und führt mit hoher Wahrscheinlichkeit zu Unfällen. Deshalb, Es ist notwendig, dass intelligente, umfassende Überwachungsgeräte in Echtzeit den Betriebsstatus und den Umgebungszustand der Transformatorausrüstung kontinuierlich überwachen, Erkennen Sie rechtzeitig und genau verschiedene Indikatoren des Transformators selbst und der Umgebung, Führen Sie umfassende intelligente Analysen durch, Rechtzeitige Warnungen bei versteckten Gefahren, Lokalisieren Sie die versteckten Gefahren genau, Beseitigen Sie versteckte Gefahren in der ersten Zeit, und verhindern Unfälle.

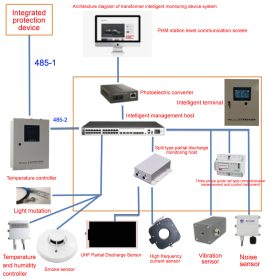

Das PHM-Online-Überwachungssystem kann mehrere Indikatoren von Transformatoren und ihrer Umgebung in Echtzeit überwachen, um den Betriebszustand von Transformatoren zu bestimmen. Einschließlich: Temperatur der Wicklung und des Eisenkerns des Transformatorkörpers, Teilentladungserkennung des Transformators, Schwingungserkennung des Transformators, Temperatur- und Feuchtigkeitserfassung der Betriebsumgebung des Transformators, Erkennung von Transformatorgeräuschen, Sofortige Entladungslichtbogenerkennung der Transformator-Kabelmuffe, und Raucherkennung. Kommunizieren Sie mit Kommunikationschips auf Stationsebene über Netzwerk-Glasfaserkommunikation, IEC61850 Protokoll.

Die Hauptfunktionen des PHM Online-Monitoring-Systems sind wie folgt::

| Überwachung des Anlagenstatus | Messung der Spulentemperatur und der Eisenkerntemperatur (Glasfaser Temperaturregler für Trockentransformatoren) Überwachung von Mutationen an elektrischen Verbindungspunkten (Überwachung von Bogenlicht) Überwachung von Teilentladungen |

| Überwachung des Umweltzustands | Messung von Temperatur und Luftfeuchtigkeit in der Betriebsumgebung Schwingungsüberwachung während des Transformatorenbetriebs Überwachung von Bodenschwingungen Überwachung von Umgebungslärm |

| Lokale Steuerungsfunktion | Lüfter-Steuerung Heizungssteuerung Steuerung der Luftentfeuchtung Mensch-Maschine-Schnittstelle |

| Bewertung des Gesundheitszustands der Geräte | Bewertung des operationellen Risikos Erinnerung an Warnhinweise |

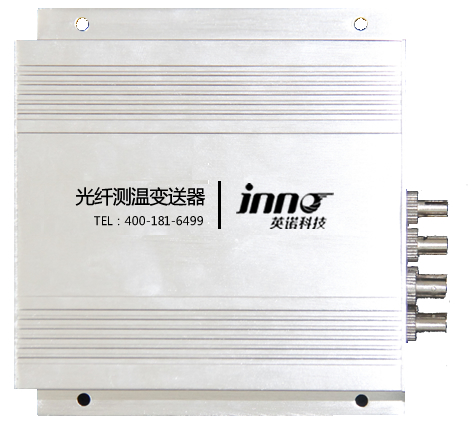

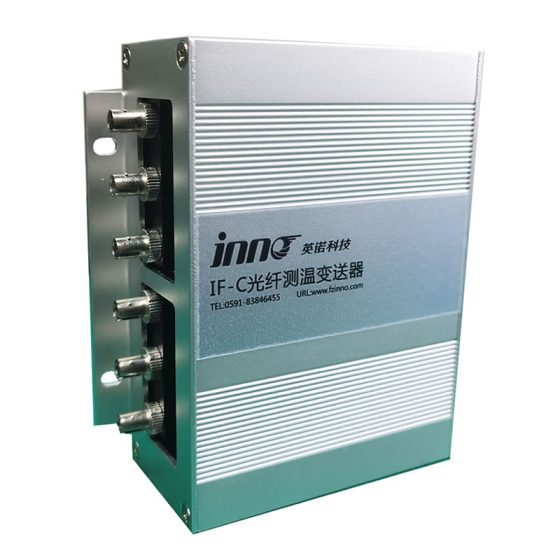

INNO faseroptische Temperatursensoren ,Temperaturüberwachungssysteme.

INNO faseroptische Temperatursensoren ,Temperaturüberwachungssysteme.