Generator stator winding fiber optic temperature measurement, stator iron core LWL-Temperaturmessung, stator temperature measurement device, stator fluorescence fiber optic temperature measurement, FJINNO’s independent research and development technology is leading, and the manufacturer’s research and development.

The importance of generator stator temperature measurement system

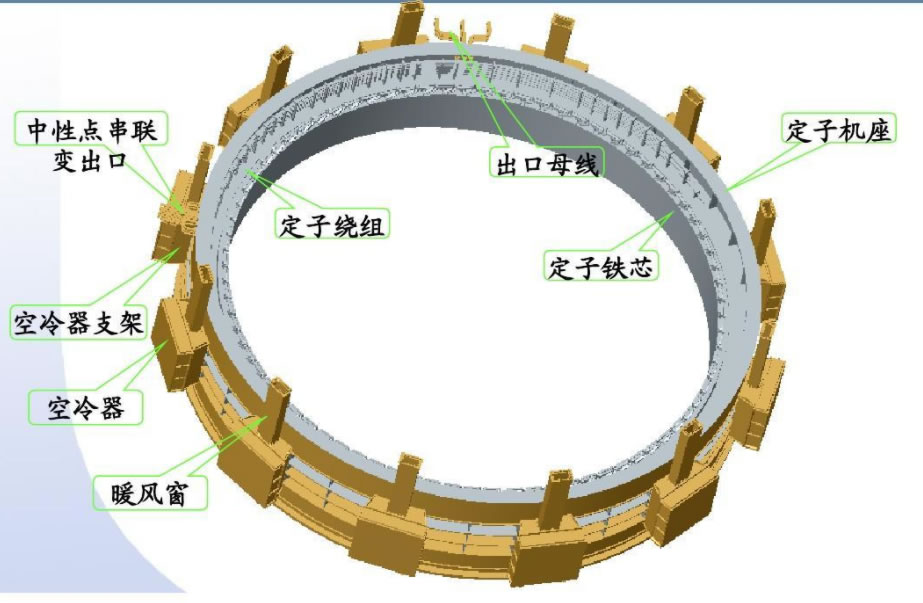

As is well known, stator temperature monitoring is one of the important parameters for safe operation monitoring of power units. Faseroptische Sensoren, als neuartiger Sensor, have been widely used in large-scale structural engineering and transformer switchgear safety monitoring. They have good insulation performance, no need for grounding shielding, und Beständigkeit gegen elektromagnetische Störungen. They also have unique application advantages in the field of unit monitoring. In order to monitor the normal operation of the hydroelectric generator in real time, it is necessary to monitor the temperature of the stator of the hydroelectric generator. The temperature measurement temperature sensor embedded in the stator of the hydroelectric generator is a necessary means. A temperature measuring element needs to be installed on the flat wire motor to understand the rated load capacity and overload capacity of the motor when operating at its rated state; Draw the limit working capacity curve of the flat wire motor within the allowable voltage variation range and at different cooling medium temperatures, in order to provide a basis for the operation of the motor; Study the relationship between the temperature of each part of the flat wire motor and the highest heating point temperature, providing a basis for evaluating and improving the structure and ventilation cooling system of the flat wire motor; Measure the insulation heat drop of the stator winding and study the insulation aging reflected by the insulation heat drop; Determine the relationship between the average temperature of the winding, the highest and lowest hot spot temperatures, and study methods for accurately monitoring and measuring the temperature of the winding.

The PT100 temperature sensor is a point measurement method that cannot accurately measure the overall temperature of the motor. In temperature measurement of motors with uneven heat distribution, the temperature control system may not be able to accurately control the motor’s operating status, resulting in damage or scrapping of the motor during measurement. In order to ensure the reliable operation of electric machines, the best solution is to use a fluoreszierendes faseroptisches Temperaturmesssystem to install temperature sensors for monitoring the operating temperature in the winding system of the stator or on the interconnection device of the winding system.

Using point type LWL-Temperaturmessung, the pressure resistance level of the temperature measuring element is arranged along the axial direction of the rod at the position where the measuring points are arranged, closely adhering to the copper strand wire of the rod. During the production process of the online rod, das temperature measuring optical fiber is buried, and then the optical fiber is led out and connected to the instrument for testing.

From the technical aspects of accuracy, reliability, installation and maintenance difficulty, as well as theoretical analysis, it is believed that fluorescent fiber optic temperature measurement is more suitable for temperature monitoring of hydroelectric generators.

Faseroptischer Temperatursensor, Intelligentes Überwachungssystem, Verteilter Glasfaserhersteller in China

|

|

|

INNO faseroptische Temperatursensoren ,Temperaturüberwachungssysteme.

INNO faseroptische Temperatursensoren ,Temperaturüberwachungssysteme.