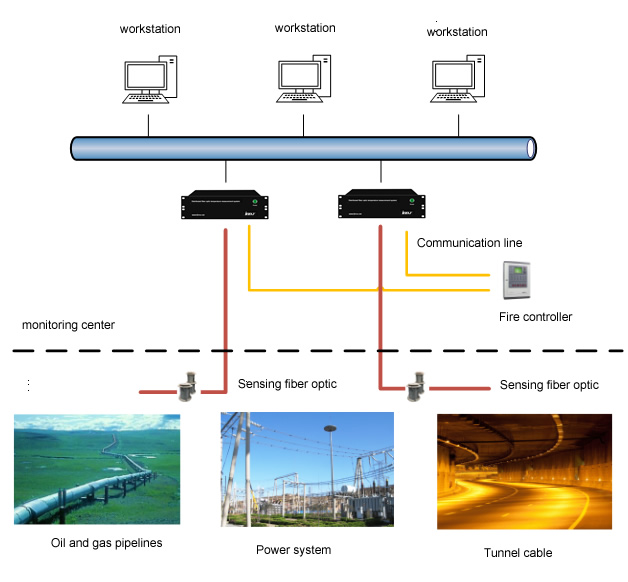

The distributed fiber optic linear temperature sensing fire detector fully meets the standard requirements. It can be applied in various long-distance temperature and fire monitoring locations, with a single channel measuring a distance of up to 5 Kilometer. The product is designed with 4 measurement channels. The product adopts distribueret fiberoptik temperature measurement technology based on Raman scattering to achieve real-time fire and temperature monitoring for long-distance pipeline corridors, tunnels, pipelines, cables, og andre steder.

The distributed fiber optic linear temperature sensing fire detector system can comprehensively utilize real-time temperature, temperature rise/drop rate, temperature rise/drop trend, and other analysis to achieve continuous monitoring. It can accurately display the temperature status of the entire fiber optic at any position at any time, timely alarm and accurately locate when a fire occurs in the monitoring area.

Advantages of using ROTDR fiber optic sensing for detection

Distributed – the backend instrument obtains the temperature distribution field of the spatial curve at the sensing fiber, which is different from traditional point temperature sensing that obtains temperature distribution through data processing. The temperature value measured by ROTDR at each point is real;

Positioning – According to the principle of ROTDR, the temperature change along the fiber optic is determined by the reflection and scattering of light (similar to radar principle), so the location of abnormal temperature can be easily and quickly located

The singularity of measurement – the temperature result is independent of parameters such as stress, pressure, and loss, and can still work normally under harsh working conditions

Long distance – up to 30km. It can be suitable for applications with a large range and multiple measurement points. Easy deployment, whether using single-mode or multimode fibers, suitable fiber optic and deployment plans can be found based on specific engineering situations.

Wide temperature measurement range – using the latest technology and special temperature measuring optical fibers, the temperature measurement range can be between -200 to 1000 °C

The entire optical cable is not only used for signal transmission, but also for temperature detection. The temperature detection coverage is 100% of its total length. The setting of the alarm area can be freely set within the entire length of the optical cable through software. The alarm positioning accuracy is high, and the detection area can reach a minimum of 1 måler. No matter how the on-site partition changes, it can meet the requirements

The alarm detection logic for each partition can achieve any combination of three methods: maximum temperature within the partition (constant temperature), temperature rise rate within the partition (differential temperature), and the difference between the highest temperature within the partition and the average temperature within the partition (uniformity of partition temperature), ensuring early and reliable alarms are achieved

The alarm detection logic for each partition can achieve any combination of three methods: maximum temperature within the partition (constant temperature), temperature rise rate within the partition (differential temperature), and the difference between the highest temperature within the partition and the average temperature within the partition (uniformity of partition temperature), ensuring early and reliable alarms are achieved

Provide fire spread direction judgment function for linear spaces such as tunnels, facilitating the emergency monitoring system to make timely and correct responses;

Provide continuous temperature monitoring for the entire fiber optic cable line, and the system also has fault self detection function. When the fiber optic cable fails, the specific location of the breakpoint can be indicated on the full length curve of the cable, which is conducive to system fault monitoring and rapid maintenance;

The system installation is very simple, using a single optical cable for signal transmission and detection. When installed on site, the installation work can be easily completed by fixing the detection optical cable;

·The detection part is completely transmitted through optical fiber, which is inherently safe for explosion and lightning protection, and can completely eliminate the influence of electromagnetic interference;

·The fiber optic cable has excellent durability design, with a detection cable lifespan of up to 30 years. It has resistance to environmental impacts such as temperature, pressure, and humidity fluctuations, and is also suitable for air with high levels of dust and corrosive substances;

·The system integration is convenient and can be directly connected to conventional fire alarm systems through communication interfaces. Derudover, the DTS system supports open communication interfaces, making it easy to achieve system integration at the controller level.

·Distributed temperature sensing optical fiber is the best method for fire monitoring in highway tunnels. It is explicitly stated in the fire safety regulations that the use of fiber optic distributed temperature monitoring systems is recommended for tunnel fire monitoring.

INNO fiberoptiske temperatursensorer ,Systemer til temperaturovervågning.

INNO fiberoptiske temperatursensorer ,Systemer til temperaturovervågning.