Filo optic e ʻea sensor resistance, Founga vakaiʻi ʻo e ʻatamai poto, Tufaki e filo optic ʻi Siaina

|

|

|

Characteristics of Distributed Fiber Optic Temperature Measurement System

(1) Non electric measurement technology

In the past, manual and electronic measurements were often used for parameter measurement in some hazardous situations. Distributed fiber optic temperature measurement technology has innovated and adopted on-site non electric measurement technology, achieving true intrinsic safety.

(2) Fast response speed, complete machine response time:<2 sekoni ʻe, this indicator is the most important technical indicator of the fiber optic distributed temperature monitoring system. Fast response speed, fast system signal acquisition speed, fast alarm speed, completely eliminate safety hazards caused by long alarm cycles. The new generation of high-speed signal processors represents the highest level in China, with a response speed of 2 seconds for instruments.

(3) It can achieve single point temperature measurement, positioning, and point by point alarm in case of faults. ʻI he taimi ʻoku hoko ai ha fakatokanga, it can not only output signals in different zones, but also accurately locate the distributed detection fiber optic position. The positioning accuracy is less than 1 mita ʻe, which is conducive to the accurate execution of fire protection work and maintenance. The temperature of each detector can be clearly detected.

(4) Distributed continuous fiber optic temperature measurement has extremely high accuracy in China. In the past, distributed fiber optic temperature measurement applications generally achieved an accuracy of 3 ° C -5 ° C. After using certain software and hardware technologies in the system, the accuracy can be improved to 1 ° C, making the system more reliable and applicable for measurement.

(5) The technological advantage of sensors is that the distributed fiber optic temperature measurement system uses an all fiber passive component, which has incomparable advantages and characteristics compared to ordinary sensors. It is inherently explosion-proof, non electric sensing, chemically stable, has a long transmission distance, and can be used for absolute measurement of external parameters. This characteristic has aroused great interest in the field of sensors. Becoming a hot topic in the field of sensing research. Distributed fiber optic sensing technology represents the development trend of the new generation of sensing technology. Its industry has been recognized as one of the most promising high-tech industries both domestically and internationally. It has attracted worldwide attention for its high technological content, good economic benefits, strong penetration ability, and broad market prospects.

(6) A solution to safety monitoring: Safety monitoring focuses on addressing the hidden dangers in current heating pipelines, with a focus on solving the fiber optic distributed temperature monitoring and warning system for pipelines.

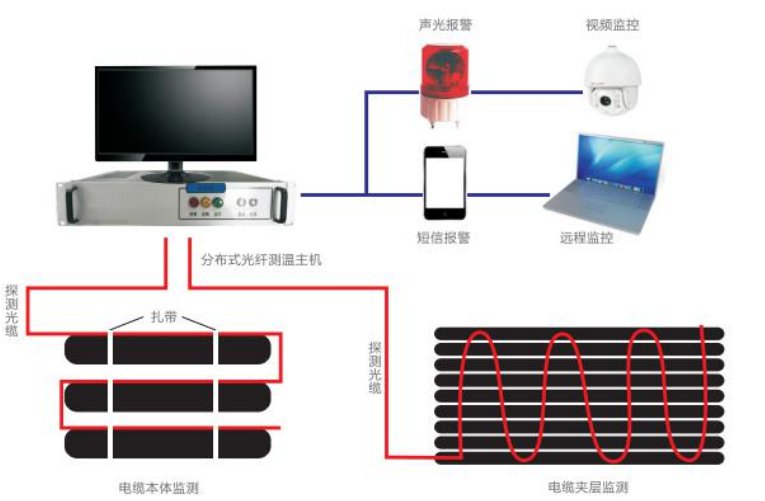

(7) Data can be transmitted to the temperature measurement host for sound, light, and SMS alarms, achieving linkage with fire protection.

The functional characteristics of the software program interface for distributed fiber optic temperature measurement cables

(1) Using distributed fiber optic temperature sensing devices to sense cable temperature and position information for signal detection and transmission, achieving no electricity detection and intrinsic safety explosion-proof;

(2) Using advanced distributed fiber optic temperature sensing as the measurement unit, with advanced technology and high measurement accuracy;

(3) Distributed temperature sensing optical cables have a long-term operating temperature range of -40 ℃ to 150 ° C, with a maximum of 200 ° C, and a wide range of applications;

(4) Adopting a single loop measurement method with a detector, the installation is simple and the cost is low; Can leave redundant spare cores;

(5) Real time display of temperature in various zones, and the ability to display historical data and change curves, as well as average temperature changes;

(6) The system has a compact structure, simple installation, and convenient maintenance;

(7) Through software, different warning and alarm values can be set according to actual situations; The alarm methods are diverse, including constant temperature alarm, temperature rise rate alarm, and temperature difference alarm.

(8) Through software, data can be queried: point by point query, alarm record query, interval query, historical data query, and report printing.

ʻIkai ha kalava optic e mafana ʻo e ʻea ,founga vakaiʻi ʻo e māfana ʻo e ʻeá.

ʻIkai ha kalava optic e mafana ʻo e ʻea ,founga vakaiʻi ʻo e māfana ʻo e ʻeá.