Kihisio cha joto la macho ya Fiber, Mfumo wa ufuatiliaji wa akili, Kusambazwa fiber optic mtengenezaji katika China

|

|

|

Overview of High Temperature Fiber Optic Solutions

The high-temperature fiber optic solution is a comprehensive solution that utilizes special fiber optic materials, Teknolojia, and equipment to specifically address the needs of fiber optic communication and sensing in high-temperature environments. In many industries, Utafiti wa kisayansi, aerospace and other fields, ordinary optical fibers cannot work stably in high temperature environments, so this solution has emerged. Below, we will provide a detailed introduction to high-temperature fiber optic solutions from several aspects.

How does high-temperature resistant optical fiber form the basis of high-temperature optical fiber solutions?

High temperature resistant optical fiber is a key component of high-temperature optical fiber solutions. The key to the use of high-temperature resistant optical fibers in high-temperature environments lies in their special materials and manufacturing processes, mainly reflected in the fiber core and fiber coating. Fiber optic cores typically use high-temperature glass and ceramic materials, which have excellent high-temperature stability and oxidation resistance, ensuring long-term stable transmission of optical signals in high-temperature environments. Kwa mfano, in the high-temperature slag measurement scenario in the steel and metallurgical industries, if ordinary optical fibers are used, their fiber cores may be functionally damaged due to high temperatures, while fiber cores made of this special material can work normally. The fiber optic coating uses high-temperature resistant materials such as aluminum phosphate to protect the fiber optic core from external factors. In high-temperature environments, there may be various chemicals, impurities, Nk. Without high-temperature resistant coatings for protection, fiber cores are easily corroded or interfered with. Wakati huo huo, high-temperature resistant optical fibers have many advantages, such as being able to operate in high-temperature environments, making them suitable for many special fields, such as navigation, communication, and control in the aerospace industry; It also has low signal loss and high signal transmission speed, ensuring the quality and speed of signal transmission; And it has high corrosion resistance and anti-interference performance, allowing it to be used freely in harsh environments, playing an important role in the measurement and monitoring of temperature, Shinikizo, flow and other parameters in petrochemical, thermal power generation, nuclear power and other fields.

How do fluorescent fiber optic sensors monitor high temperatures?

What is the principle of using fluorescent fiber optic sensors to monitor high temperatures?

Fluorescence fiber optic sensors monitor high temperatures based on the stable dependence of fluorescence lifetime on temperature. This relationship is not affected by factors such as excitation light intensity, fiber bending, and joint loss. In this type of sensor, there are specific fluorescent substances, and the fluorescence lifetime of the fluorescent substances will change accordingly when the temperature changes. Kwa mfano, in places with complex working environments such as switchgear (high electromagnetic interference, high temperature, narrow space, Nk.), it is necessary to accurately monitor the temperature of key connection points to prevent overheating and arc accidents. Fluorescent fiber optic sensors can play a role. Traditional temperature sensors may have inaccurate readings due to electromagnetic interference, but fluorescent fiber optic sensors are not affected by such interference and are therefore more reliable in this environment.

How can fluorescent fiber optic sensors achieve high temperature monitoring in different scenarios?

In the field of power, fluorescent lifetime fiber optic temperature sensors perform well in high-temperature monitoring scenarios of equipment such as switchgear and transformers. In the switchgear, sensors can monitor the temperature of critical connection points. For transformers, high temperatures may cause insulation material aging and lead to faults. Fluorescent lifetime fiber optic sensors can be installed in the oil or near the windings of transformers to monitor temperature, ensuring normal operation and extending the service life of transformers. In the medical field, such as in magnetic resonance imaging (MRI) Teknolojia, superconducting magnets must be cooled to extremely low temperatures, and fluorescence lifetime fiber optic temperature sensors can be used to monitor the performance of the cooling system to ensure that the magnets are at the correct temperature. Wakati huo huo, this sensor can also be used for temperature monitoring or thermal therapy in clinical medicine, which can monitor the patient’s temperature and ensure the safety and effectiveness of the treatment. Due to its high accuracy and fast response, it is very suitable for situations that require strict temperature control. In the field of experimental science, in chemical experiments, the temperature of the reactants directly affects the reaction rate and the generation of products. The use of fluorescence lifetime fiber optic sensors can not only monitor accurate temperature in real time, but also avoid measurement errors caused by light sources or electromagnetic interference; In biological research, processes such as cell culture and enzyme reactions require very precise temperature control. Fluorescence lifetime fiber optic sensors are highly suitable for such sensitive environments due to their immunity to electromagnetic interference and chemical inertness; In the development experiments of new materials such as high-temperature superconductors, it is necessary to conduct them under specific temperature conditions. Fluorescence lifetime fiber optic sensors can provide necessary temperature distribution information to help scientists understand the properties of the materials.

What is the role of distributed optical fiber in high temperature monitoring?

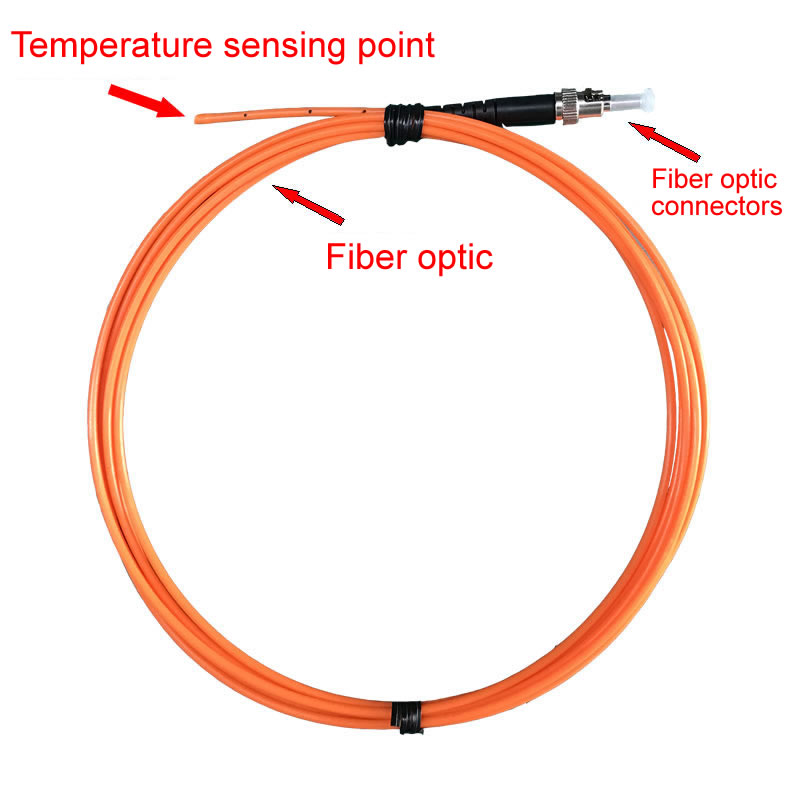

How does the principle of distributed optical fiber ensure its effectiveness in high temperature monitoring?

The distributed fiber optic temperature monitoring device relies on Raman time-domain analysis fiber optic temperature measurement technology to achieve temperature monitoring function based on the backward Raman scattering effect: the interaction between laser pulses and fiber molecules scatters (where Raman scattering is due to the thermal vibration of fiber molecules), producing a Stokes light longer than the wavelength of the light source and an Anti Stokes light shorter than the wavelength of the light source. The intensity of the anti Stokes light signal is related to temperature, while the Stokes light signal is independent of temperature. From the ratio of the anti Stokes optical signal to the Stokes optical signal intensity at any point within the optical waveguide, the temperature at that point can be obtained, and then the optical time domain reflectometry (OTDR) technology can be used to locate the hotspot, thereby achieving distributed measurement of the temperature field along the fiber optic cable.

What are the applications of distributed optical fiber in different high-temperature scenarios?

In terms of monitoring the operation of power cables, distributed optical fibers, due to their continuous and distributed measurement characteristics, can timely grasp the operating status of power cables by monitoring their temperature values. They can continuously measure temperature and display the temperature change curves of each point on the line and the entire line in real time, avoiding cable failures. Moreover, different alarm values (such as 60, 70, 80) can be set for graded alarms in different areas of power cables. There are also various types of alarms, such as constant temperature alarm, differential constant temperature alarm, temperature rise rate alarm, Nk., to prevent fire accidents caused by high temperature at various cable joints in cable trenches. In the chemical industry, it can be applied to temperature monitoring of equipment such as pipelines and storage tanks, to timely detect and deal with potential safety hazards caused by high temperatures, and to ensure the safe operation of chemical production. It can accurately monitor the temperature conditions at various locations of chemical equipment, such as the surface of reaction vessels or around material transfer pipelines. Excellent temperature measurement capabilities can also be utilized in facilities such as tunnels and urban underground pipe galleries, enabling accurate and rapid monitoring of the temperature conditions of these facilities and providing strong guarantees for their safe operation.

What is the principle and application of fiber Bragg grating temperature sensor?

What is the working principle of fiber Bragg grating temperature sensor?

Fiber Bragg Grating Temperature Sensor utilizes the inherent temperature sensing characteristics of fiber Bragg Grating for temperature measurement. When the measured temperature used for fiber Bragg gratings changes, it will cause corresponding changes in the n (core mode effective refractive index) and ∧ (grating period) of the fiber Bragg grating, resulting in a drift of λ B (wavelength of reflected light). Conversely, by detecting the drift of λ B, information about the measured temperature can be obtained. This sensor uses wavelength encoding technology to eliminate the effects of light source power fluctuations and system losses, making it suitable for long-term monitoring. Moreover, a temperature sensing system composed of multiple fiber Bragg gratings, using a single optical cable, can achieve quasi distributed measurement. Zaidi ya hayo, temperature is a factor that directly affects the wavelength variation of fiber Bragg gratings. People often directly apply bare fiber Bragg gratings as temperature sensors. Hata hivyo, in order to make fiber Bragg gratings have strong mechanical strength and longer lifespan, and to improve their sensitivity to temperature response, they also need to be packaged. Common packaging methods include substrate, tube, and polymer packaging.

What are the applications of fiber Bragg grating temperature sensors in different scenarios?

Monitor and fire alarm the temperature of high-voltage power switchgear, high-voltage cable joints, and other locations in power plants, substations, and other places. Because fiber Bragg grating temperature sensors have the characteristics of small size, unyeti wa juu, Upinzani wa kutu, na upinzani dhidi ya kuingiliwa kwa umeme, they are very suitable for scenarios that require precise monitoring of the health status of power equipment and complex environments (such as the presence of electromagnetic interference and the possibility of high temperatures). Fiber Bragg grating sensors can also be used for health monitoring of large structures such as buildings, Madaraja, aircraft, and ships in other aspects of the industrial field. Kwa mfano, in bridges, by installing fiber Bragg grating temperature sensors at key structural locations, temperature changes can be monitored and the structural health of the bridge can be evaluated based on temperature changes (temperature changes may cause stress changes in the bridge structure, Nk.); It can also be installed around high-temperature components such as engines on airplanes to monitor temperature and evaluate the working status of components.

What are the elements involved in high-temperature fiber optic solutions?

Elements of high-temperature resistant optical fiber materials

As mentioned above, high-temperature resistant optical fiber materials are the foundation. The fiber core adopts high-temperature glass and ceramic materials, and the coating uses high-temperature resistant materials such as aluminum phosphate. These special materials ensure that the basic performance of the fiber is not damaged in high-temperature environments, and are the cornerstone of achieving high-temperature fiber solutions. Without such high-temperature resistant materials, the communication and sensing functions of optical fibers in high-temperature environments will inevitably be greatly reduced, making it impossible to carry out various monitoring and communication tasks in high-temperature scenarios such as metallurgy and aerospace.

High precision sensor technology elements

Sensor technologies including fluorescent fiber optic sensors, fiber Bragg grating temperature sensors, Nk. are an important part of high-temperature fiber optic solutions. Fluorescent fiber optic sensors, with their precise monitoring of temperature changes (based on the relationship between fluorescence lifetime and temperature) and applicability in different scenarios, as well as the ability of fiber optic grating temperature sensors to accurately and reliably measure temperature using the characteristics of fiber optic gratings (temperature changes cause wavelength drift of reflected light), provide high-precision technical means for temperature monitoring in high-temperature environments. Whether it is temperature monitoring of switchgear in industrial production or measurement of special temperature environments in scientific research experiments, these high-precision sensor technologies are indispensable.

Stable distributed fiber optic monitoring technology elements

Distributed fiber optic monitoring technology is a key component of high-temperature fiber optic solutions. By utilizing its unique Raman scattering effect to monitor temperature conditions over a large area, this technology ensures the ability to detect temperature distribution in long-distance, large-area target regions. Kwa mfano, in scenarios such as power cable lines that are several kilometers or even tens of kilometers long, and large-scale pipeline network layouts in the chemical industry, distributed optical fibers can accurately obtain temperature information at various locations, while also providing the function of accurately locating abnormal temperature points. This provides comprehensive and intuitive data support for timely detection and handling of high-temperature related hazards.

What are the advantages and limitations of high-temperature fiber optic solutions?

What are the advantages of high-temperature fiber optic solutions?

Adapting to high temperature environments: The high-temperature resistant optical fibers in the high-temperature fiber solution can work normally at high temperatures, without problems such as light aging, reduced transmission rate, and significant signal attenuation caused by high temperatures like ordinary optical fibers, ensuring the stability and reliability of various applications in high-temperature environments. Kwa mfano, when monitoring or communicating near the high-temperature furnace in a steel plant, it can withstand the high temperature environment of the furnace and accurately transmit data and signals.

Strong anti-interference ability: Fiber optic itself is an electrically insulating material, and fiber optic sensors use optical signals as carriers to transmit signals. Basi, the entire high-temperature fiber optic solution has high anti-interference ability, and can perform temperature monitoring, data transmission, and other work normally without interference in some strong electromagnetic interference scenarios (such as high-voltage switchgear, near motors, Nk.). Wakati huo huo, optical fiber materials have stable chemical properties and good corrosion resistance, which can resist chemical corrosion that may occur in high-temperature environments, such as strong acid or alkali environments in chemical enterprises.

High precision and distributed measurement advantages: Fluorescent fiber optic sensors and fiber Bragg grating temperature sensors can achieve high-precision temperature measurement and monitoring. In the field of experimental science, fluorescent fiber optic sensors can accurately sense subtle temperature changes during the experimental process, while fiber optic grating temperature sensors can accurately measure temperature changes in a small area of power switchgear to prevent fires; Moreover, distributed optical fibers can achieve distributed measurement over a large area, obtaining comprehensive and complete temperature distribution information, providing high-precision and all-round data basis for disaster prevention (such as fires caused by cable overheating, explosions caused by local overheating of chemical equipment, Nk.).

What are the limitations of high-temperature fiber optic solutions?

Relatively high cost: Due to the need for special materials and manufacturing processes for high-temperature resistant optical fibers, the high investment in research and development of high-precision sensor technology, and the high cost of equipment and systems related to distributed optical fiber monitoring technology, the overall cost of high-temperature optical fiber solutions is much higher compared to traditional solutions used at room temperature or temperature monitoring solutions using ordinary materials. For small businesses with limited budgets or some simple temperature monitoring scenarios, it may be difficult to afford such cost investments.

Some application scenarios are limited: Although high-temperature fiber optic solutions can work well in many high-temperature scenarios, for certain special extreme high temperature and complex environments (such as ultra-high temperature combustion flame centers), existing high-temperature resistant fiber optic materials and sensors may still not fully meet the needs. In this case, further exploration and development of more suitable materials and technological means are still needed. Wakati huo huo, optical fiber is a relatively fragile material that may pose a risk of damage in high-temperature environments that require high-intensity mechanical impact. If additional protective measures are not taken, it may affect its functionality and lifespan.

Vihisio vya joto vya macho vya INNO fibre ,Mifumo ya ufuatiliaji wa joto.

Vihisio vya joto vya macho vya INNO fibre ,Mifumo ya ufuatiliaji wa joto.