Fiberoptisk temperatursensor, Intelligent övervakningssystem, Tillverkare av distribuerad fiberoptik i Kina

|

|

|

catalogue

1. Project Overview 1

1.1 Application Background 1

1.2 Significance of Busbar Temperature Monitoring 2

1.2.1 Provide technical support for the safety of busbar equipment

1.2.2 Inherent Safety of Equipment 2

1.2.3 Application Purpose 2

Design Specification for Scheme 2

2.1 Design Principles 2

3 Distributed Fiber Optic Online Temperature Monitoring System 3

3.1 IFTS-MK distributed single-mode fiber temperature measurement host 3

3.2 Temperature Measurement Principle 4

3.3 System Technical Advantages 5

3.4 Equipment Characteristics 6

Solution for Fiber Optic Temperature Measurement System in Bus Duct 4

4.1 Overall Plan 7

4.2 Design Scheme for Distributed Fiber Optic Temperature Measurement System 8

4.3 Technical Features 9

4.4 System Software 9

5. Laying Plan for Temperature Sensing Fiber 11

5.1 Construction Method 11

5.2 Construction Training 11

5.3 Fiber Optic Laying 11

5.3.1 Fiber optic laying method for bus duct 11

5.3.2 Fiber optic laying method for busbar joints 12

5.3.3 Setting of temperature sensing fiber margin 13

5.3.4 Fusion splicing of optical cables 13

5.3.5 Fixing of optical cable splice box 14

6 After sales Service Commitment 14

6.1 After sales warranty service 14

6.1.1 Product Warranty Period 14

6.1.2 After sales response time 14

6.1.3 Service after the expiration of the warranty period 14

6.2 Technical Services and Training 14

1. Project Overview

1.1 Application Background

The intelligence and standardization of temperature monitoring in busbar power supply systems are the basis for real-time power transmission status, temperature conditions, and even patrol detection.

In the practical application of busbars, due to long-term operation in the air and the influence of surrounding temperature and humidity, thermal expansion and contraction, surface scaling, oxidation or corrosion may occur, resulting in loose contacts and poor contact, especially in some large buildings (such as large factories, super high-rise buildings, etc.) where the installation position of busbars cannot be monitored manually. Users often neglect the safety management of busbars. Once the temperature of the busbar joints during operation is abnormally high, it may lead to fires or major safety and quality accidents, causing huge and irreparable personal injury and economic property losses to enterprises.

The bus duct is in a fully enclosed state during operation and is generally in a long-term live state, making daily maintenance and inspection very inconvenient. Därför, it is necessary to monitor the temperature of the bus duct to improve its reliability.

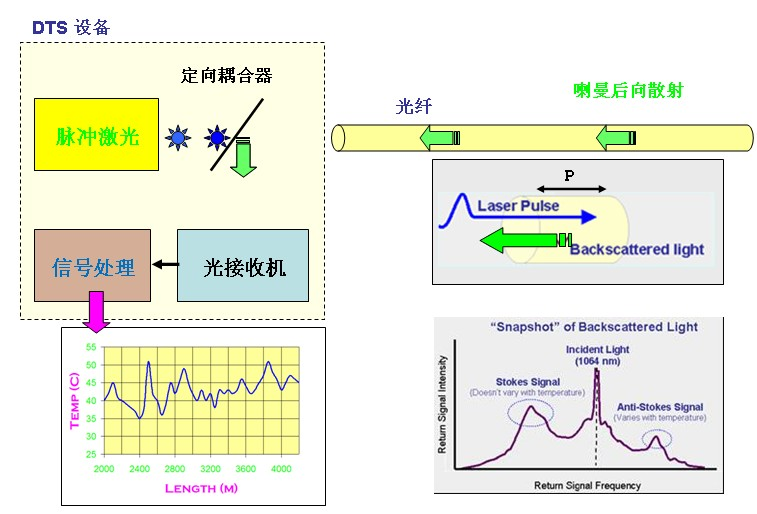

Distribuerad temperaturavkänning (DTS (DTS)) is currently the most advanced temperature measurement technology internationally. DTS distributed fiber optic temperature sensing is completely different from traditional temperature sensing systems based on electrical signals. Whether it is the difficulty of measurement technology, the content and indicators of temperature measurement, or the occasions and scope of measurement, it has been raised to a new stage. The distributed fiber optic temperature sensor system can measure and display the temperature values of various points on the entire continuous fiber optic cable in the form of a continuous function of distance. This technology only requires one optical fiber to measure temperature at a distance of ten kilometers. Domestic and international engineering application experience has shown that distributed fiber optic temperature sensing systems are highly effective monitoring devices for temperature monitoring in power systems.

A large number of practical applications and tests have proven that distributed fiber optic temperature sensing technology has excellent stability and reliability. Ytterligare, optical fibers have the characteristics of corrosion resistance, high temperature resistance, no static electricity, and no radiation. This enables the system to provide stable, pålitlig, and economical solutions for various industrial needs based on temperature detection.

Sammanfattningsvis, fiber optic temperature sensing technology is currently the most advanced temperature sensing technology internationally, with inherent explosion-proof, strong electromagnetic interference resistance, bra elektrisk isolering, lightning protection, high precision, light weight, and small size. It can simultaneously measure the temperature distribution on the entire fiber optic cable, surpassing all traditional quasi distributed temperature measurement or alarm systems. It is also a highly intelligent and automated monitoring technology, which does not require manual inspection of the monitored area. The monitoring room screen can display temperature information of each point in the entire monitoring area; When there is an overheating point, it can sound or light an alarm, or send it to relevant personnel via SMS. It can effectively solve the problem of temperature monitoring in complex environments that traditional temperature measurement techniques could not solve before. It can accurately predict hot spots before accidents occur, with a positioning accuracy of 1 meter, and display the evolution of hot spot temperature, truly achieving preventive measures. Därför, distributed fiber optic temperature sensors have received widespread attention worldwide and have begun to be widely applied.

1.2 Significance of Busbar Temperature Monitoring

Monitoring the temperature of the busbar has the following significance:

Safely increase the current carrying capacity of the circuit;

Can achieve periodic state monitoring;

Drive external alarm or other emergency systems;

Discovering hotspots (especially bus joints with potential accident hazards) and other environmental anomalies.

1.2.1 Provide technical support for the safety of busbar equipment

With the national standardization requirements for high-risk environments and the development of intrinsic safety optical communication technology, some technologies in optical communication have gradually provided a technical platform for the application of sensing fields, and distributed fiber optic sensors are one of them. It can scientifically and inherently safely complete the monitoring work of the busbar, and is the best choice for busbar temperature monitoring.

Real time online monitoring of bus temperature can be achieved. It can provide sound and light warnings, alarms, etc. for safety signals such as high and low temperatures and abnormal conditions.

1.2.2 Intrinsic safety of the equipment itself

This product adopts distributed fiber optic detection technology to achieve temperature measurement without electricity, which is truly inherently safe. Strong anti electromagnetic induction and anti-interference ability, very suitable for temperature monitoring applications in the coal mining industry, with great technical and safety advantages.

1.2.3 Application purpose

Distributed fiber optic temperature monitoring system is applied to various busbars and bus ducts, using distributed fiber optic measurement technology for real-time temperature monitoring, thereby achieving safe monitoring of the operation of busbar equipment.

INNO fiberoptiska temperatursensorer ,System för temperaturövervakning.

INNO fiberoptiska temperatursensorer ,System för temperaturövervakning.