Fiberoptisk temperatursensor, Intelligent övervakningssystem, Tillverkare av distribuerad fiberoptik i Kina

|

|

|

Advantages of Transformer Fiber Optic Temperature Sensor

- Strong ability to resist electromagnetic interference

Fiber optic temperature sensors are not affected by electromagnetic fields, making them highly suitable for applications in high-voltage power equipment such as transformers. Traditional temperature measurement methods may be severely interfered with in electromagnetic/radio frequency environments, while fiber optic sensors can function normally. - High precision and high sensitivity

Fiber optic temperature sensors can provide high-precision and high-sensitivity temperature measurement. Due to the intrinsic relationship between fluorescence lifetime and temperature, which is independent of the intensity of light, self calibrating fiber optic temperature sensors can be made without the need for frequent calibration. - Strong adaptability to installation environment

Fiber optic temperature sensors are suitable for various harsh environments, including flammable, sprängämne, corrosive environments, as well as harsh conditions such as lightning strikes and outdoor environments. Ytterligare, they are also suitable for places with limited installation space and special requirements for sensor size. - Long lifespan and high reliability

Fiber optic temperature sensors have a long service life and high reliability, making them suitable for long-term monitoring of temperature changes in transformer windings. - Real time monitoring and direct measurement

Fiber optic temperature sensors can provide real-time temperature monitoring and directly measure the hot spot temperature of transformer windings, which is of great significance for evaluating the operating status, load planning, asset management, and end-of-life of transformers. - High cost-effectiveness

Despite the high cost of early fiber optic systems, with the development of technology, the cost of fiber optic temperature sensors has been significantly reduced, especially in small, medium, and distribution transformers. Fiber optic temperature sensors provide an economical, direct, accurate, and real-time solution for measuring hotspot temperatures.

Key factors for selecting manufacturers of transformer fiber optic temperature sensors

1、 Technical strength

(1) Mastery of core fiber optic sensing technology

Fiber optic sensing technology is the foundation of transformer fiber optic temperature sensors. Common sensing technologies include fiber Bragg gratings, fluorescent fiber optic temperature measurement, and other techniques. In terms of fiber Bragg grating technology, it is formed by exposing and etching several Bragg gratings with different center wavelengths along the longitudinal direction of the fiber through ultraviolet radiation. When the temperature changes, the period and refractive index of the gratings will change, causing changes in the reflected wavelength to achieve temperature measurement. Fluorescent fiber optic temperature measurement uses fluorescent substances to emit fluorescence under specific light excitation, and the intensity and lifetime of their fluorescence are closely related to temperature. Till exempel, the ambient temperature can be calculated by measuring the decay time constant of the fluorescence afterglow. If manufacturers have in-depth research and rich practical experience in these key fiber optic sensing technologies, and master the entire technical process from fiber optic sensor design to signal processing, they can gain an advantage in technology. In China, many factories have already performed well in the field of fluorescent fiber temperature measurement. Fuzhou innovation elektronisk Scie&Tech Co., Ltd. is one of the leading manufacturers of fiber optic thermometers in China, with advanced production equipment and technical teams. Their products enjoy a high reputation in the Chinese and even international markets. Their fluorescent fiber optic temperature measurement system can accurately measure temperature in special environments such as high voltage and strong electromagnetic interference.

(2) Multi point temperature measurement capability

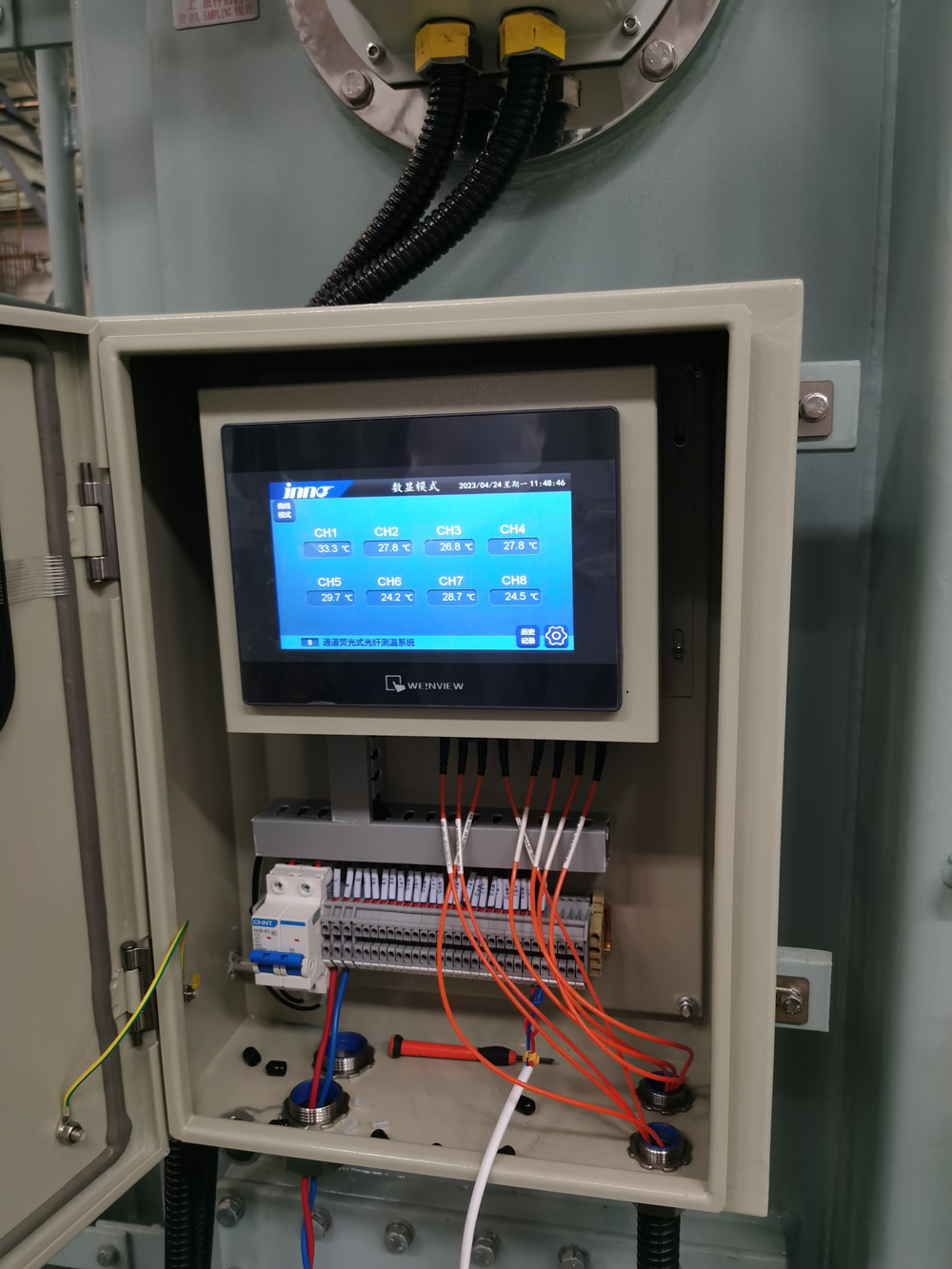

Transformers are large equipment, and multiple measurements are often required to fully understand their temperature distribution. This requires manufacturers to have the ability to achieve multi-channel fiber optic temperature measurement. Excellent manufacturers can integrate multiple sensors for multi-point deployment and control within the same fiber optic network. Till exempel, in large oil immersed transformers, it may be necessary to arrange temperature measurement points at multiple locations of the high and low voltage windings, järnkärnor, and oil passages. Manufacturers need corresponding technical solutions to ensure that these multiple temperature measurement points can be accurately measured, and that signal transmission is stable and does not interfere with each other.

(3) Anti interference technology level

There is a complex electromagnetic environment inside the transformer, with strong magnetic and electric fields, so the transformer fiber optic temperature sensor must have strong resistance to electromagnetic interference. Manufacturers need to have relevant technical reserves in multiple aspects. Firstly, in terms of fiber selection, till exempel, using fiber optic materials with excellent shielding performance. Secondly, the structural design of the sensor should be able to prevent electromagnetic interference from affecting the internal detection signal. Till exempel, by utilizing the dielectric and optical transmission characteristics of optical fibers, a fully insulated sensor structure can be designed to physically avoid the impact of electromagnetic interference on the measurement. Furthermore, in terms of signal processing algorithms, digital filtering, signal averaging, and other algorithms can be used to improve the anti-interference ability of signals, ensuring accurate temperature measurement even inside transformers with high magnetic field strength. FJINO’s fiber optic sensor can operate in high voltage, high temperature, high magnetic field, and extremely strong electromagnetic interference environments. It adopts certain anti-interference techniques to ensure the accuracy and stability of data measurement, and the structure helps to resist external interference.

2、 Product Quality

(1) Ultra high precision temperature measurement

Temperature measurement accuracy is a key indicator for measuring the quality of transformer temperature measurement optical fibers. Accurate temperature measurement helps to promptly and accurately detect potential overheating issues in transformers, thereby avoiding malfunctions. Emellertid, the accuracy of temperature measurement can be affected by various factors, such as the accuracy of the sensor itself and the transmission loss of optical fibers. Manufacturers should have high-precision calibration equipment and processes to ensure the initial accuracy of sensors, and their temperature measuring optical fibers should also maintain stable accuracy during long-term use. This involves the stability of fiber optic materials, sensor packaging technology, etc. Till exempel, the packaging of sensors must ensure that the fiber optic and detection components are not corroded or damaged under long-term immersion in transformer oil, in order to maintain measurement accuracy. Till exempel, some high-precision fiber optic temperature sensors can achieve a temperature measurement accuracy of ± 0.05 °C, which can meet the extremely high requirements for transformer monitoring scenarios.

(2) Long term stable performance

Due to the fact that transformers are generally continuous operating equipment, their temperature measuring optical fibers also need to work stably for a long time. The ideal manufacturer produces products that can still provide reliable temperature measurement after long-term operation. This requires manufacturers to strictly control multiple aspects. In terms of product material selection, high-quality optical fiber materials should have anti-aging performance, and their performance will not decline sharply due to long-term exposure to high temperature, high pressure and other environments. In terms of manufacturing technology, it is necessary to ensure a firm connection between the optical fiber, sensor, and connecting components to prevent loosening or breakage during operation. Ytterligare, a strict finished product testing system can screen out products with potential failure risks, ensuring the long-term stability of products from quality control. Till exempel, if the connection between the fiber optic cable and the sensor becomes loose after long-term operation, it may lead to inaccurate measurement data or data transmission interruptions, affecting the accurate monitoring of transformer temperature.

(3) Comprehensive reliability guarantee

The reliability of products provided by manufacturers is reflected in many aspects. In the product design phase, redundancy design should be considered, till exempel, when a component fails, it will not cause the entire temperature measurement system to malfunction. Taking fiber optic sensor networks as an example, if a sensor fails, the system can detect and locate the fault point in the shortest possible time, while taking isolation measures to avoid affecting the operation of other sensors or the entire measurement system. Ytterligare, accurate technical parameters, installation and usage precautions, expected lifespan, etc. should be provided in the product manual or user guide, so that users can use the product reasonably and have accurate expected values. And it is also necessary to provide a comprehensive after-sales service guarantee system, with clear regulations on fault response time, product repair and replacement policies, and other aspects. Till exempel, if a commitment can be made to repair or replace faulty products within a specified time, it will make users feel more at ease using the product.

3、 Industry experience and reputation

(1) Practical experience in specific fields

Rich experience in the field of electricity, especially transformers, is an advantage for manufacturers. Manufacturers with extensive application cases and experience in the power industry, especially in transformer temperature measurement, are more worthy of favor. Such manufacturers can gain a deep understanding of the special requirements of transformer equipment for temperature measuring optical fibers, including the temperature characteristics of transformers of different types (such as dry-type, oil immersed, etc.) and specifications (such as different capacities, voltage levels, etc.) during actual operation. Taking oil immersed transformers as an example, their complex internal structure, oil temperature characteristics, and heat dissipation greatly affect the temperature monitoring system. Manufacturers with practical experience in related projects can optimize their product design and installation processes based on these situations, and provide temperature measurement solutions that are more in line with actual needs. Till exempel, some manufacturers, based on years of monitoring experience in oil immersed transformers, can arrange special temperature measurement points for their heat sinks to improve the overall temperature monitoring effect.

(2) Widely recognized market reputation

Market reputation can be measured by various aspects such as customer evaluations of their products, industry recognition, etc. High quality manufacturers usually have a good brand image in the market, with their products having a certain market share and high customer satisfaction. From the perspective of customer evaluation, if users can provide feedback on the advantages of the manufacturer’s products in terms of accuracy, stabilitet, installation convenience, and after-sales service, then this is a good reference for selection. In terms of industry recognition, attention can be paid to whether the manufacturer has obtained industry related standard certification (such as technical standard certification in the power industry), or whether it has been recognized by organizations or authoritative institutions in the industry. These factors can indirectly reflect the manufacturer’s reputation in the industry. Till exempel, the FZINNO fiber optic temperature sensor product has obtained certification from authoritative institutions in the power industry and has been selected by many well-known power companies, which can indirectly reflect the reliability and quality of its products.

4、 Service Support

(1) Thoughtful support for installation and debugging

The installation and debugging of temperature measuring optical fibers for transformers are relatively complex, involving wiring and accurate installation and positioning of sensors within special equipment such as transformers. So if manufacturers can provide professional installation and debugging services or provide detailed and accurate installation guidance documents, it will greatly improve the efficiency and effectiveness of product use. Till exempel, providing installation diagrams for different types and structures of transformers, detailed installation steps and processes, and informing of taboos during the installation process. During the debugging process, it is possible to explain to the user how to calibrate the equipment and test the system performance to ensure that the temperature measurement system can operate normally. If manufacturers lack these supports, various problems may arise during the installation and debugging process, such as inaccurate temperature measurement due to incorrect sensor installation positions, and improper wiring that may affect the service life of optical fibers.

(2) Thoughtful and comprehensive after-sales maintenance

A comprehensive after-sales maintenance service is an important consideration when choosing a manufacturer. When there are problems with the product during use, the manufacturer needs to respond promptly and resolve them. This includes fast fault response time, such as committing to respond within 24 hours of receiving a fault report. And a reasonable product repair and replacement policy should be provided. If the product is damaged by non-human factors during the warranty period, it should be repaired or replaced free of charge. If the manufacturer lacks a comprehensive after-sales maintenance plan, once the product has problems, users may face long-term production stagnation or equipment malfunction, which will affect the normal operation of users from transformers to the entire production process.

The best type of transformer fiber optic temperature sensor

Types and characteristics of transformer fiber optic temperature sensors

Distributed fiber optic temperature sensor:

Principle and structure: Its principle is based on sensing temperature changes through Rayleigh scattering, Raman scattering, or Brillouin scattering in optical fibers. It is usually used to detect spatial temperature distribution, in simple terms, it can obtain temperature information at different positions along the length direction of the optical fiber. Its structure includes a detection device for analyzing scattered light at the rear and an optical fiber part as a sensing component. Till exempel, in 1997, China University of Metrology applied this principle to a coal mine temperature detection sensor system, which can detect temperatures ranging from -49 to 150 ℃ with a temperature resolution of 0 5 °C.

Features: It can continuously measure the temperature distribution along the fiber optic cable and achieve long-distance distributed measurement. Emellertid, its drawbacks are relatively high cost, system complexity, and limited spatial resolution. Dessutom, it has relatively high requirements for optical fibers, and if the fiber is damaged or its performance changes, it may affect the accuracy of the measurement. Ytterligare, due to the reliance on scattered light, external interference factors (such as pressure and other disturbances to the optical fiber that may be mistaken as temperature change signals) pose a certain risk of interference.

Fiber Bragg Grating Temperature Sensor:

Principle and structure: Mainly based on Bragg fiber sensing technology, when the temperature changes, the reflection wavelength of Bragg fiber grating will change to achieve temperature measurement. This type of sensor is made on optical fibers as a light sensing component that only reflects specific wavelengths. Till exempel, a research center in Canada discovered the photosensitive effect in germanium doped quartz fiber in 1978 and manufactured the world’s first fiber Bragg grating.

Features: This sensor can achieve high measurement accuracy. The Chinese Academy of Sciences has increased the sensitivity of the sensor to 0.02 ℃ using the metal groove packaging technology of fiber Bragg gratings, and Harbin Institute of Technology has further improved the resolution to 0.04 °C. It can conveniently perform wavelength modulation and achieve quasi distributed measurement. Emellertid, on the one hand, fiber Bragg grating sensors are relatively fragile, and the grating may be damaged under certain impact forces or stress environments, which may affect the measurement; On the other hand, it is sensitive to factors such as humidity in the environment. If it is in a humid or harsh environment, the performance of fiber Bragg gratings may gradually decline, the lifespan may be shortened, and the accuracy of temperature measurement may be affected; Ytterligare, the relatively high process costs of writing and manufacturing gratings are also factors that must be considered.

Gallium Arsenide Fiber Optic Temperature Sensor:

Principle and structure: Gallium arsenide crystal is added at the end of the optical fiber. When multiple wavelengths of light are emitted by the light source and irradiated onto the gallium arsenide crystal, the crystal absorbs different wavelengths of incident light according to temperature. The measured temperature is calculated by detecting the spectrum of the reflected light. This is a single point temperature measurement method for optical fibers.

Characteristics: Gallium arsenide material properties do not change over time, making it a true passive probe. It is all dielectric, not affected by EMI interference, has stable performance, high reliability, and performs well in strong electric and magnetic field environments, as well as high voltage resistance, chemical corrosion resistance, low loss, and other situations. Its sensor has a small volume, with a temperature sensing part of only 0.3mm. The conductor uses 62.5um optical fiber, which is soft, pålitlig, and not easily damaged during installation. Emellertid, it can only have one sensor per single fiber optic cable, unlike fiber Bragg gratings where multiple sensors can be connected in series through a single fiber optic cable; Furthermore, from the perspective of the entire system, changes in the optical path (such as fiber optic cable rearrangement, sensor re welding, etc.) can seriously affect the accuracy of temperature measurement, often requiring the complex operation of recalibration.

Fluorescent fiber optic temperature sensor:

Principle and structure: The main components include multimode optical fibers and fluorescent objects (films) installed on top of them. When a fluorescent substance is excited by light of a certain wavelength (excitation spectrum), it emits fluorescence energy. After the excitation is cancelled, the duration of the fluorescence afterglow depends on factors such as the characteristics of the fluorescent substance and the ambient temperature. The decay time (fluorescence lifetime or fluorescence afterglow time) of this excited fluorescence that decays exponentially is related to the ambient temperature. By measuring this fluorescence afterglow lifetime, the ambient temperature at that time can be known.

Characteristics: Fluorescent fiber optic temperature sensors have high precision, and their measurement can achieve high accuracy because fluorescent materials are quite sensitive to temperature changes; Fast response speed, which enables the sensor to monitor temperature fluctuations in real time and respond quickly; External interference has little impact on it, till exempel, electromagnetic interference signals that traditional temperature sensors are susceptible to have no effect on it, so it can work normally in complex electromagnetic environments; Has excellent long-term stability, mainly due to the strong durability and stability of the fluorescent material itself; And it has a wide range of applicable environmental temperatures, from as low as minus Baidu to as high as several hundred degrees Celsius.

Advantages of Fluorescent Fiber as Transformer Fiber Temperature Sensor

Excellent electrical insulation ensures safe and reliable measurement:

For transformers, many devices operate in high voltage environments, and traditional temperature sensors may pose safety hazards due to electrical insulation issues if used in such scenarios. Fluorescent fiber optic sensors, with their fiber optic material being an electrical insulator, pose no potential risk of conductivity in high-pressure environments, avoiding the possibility of arcing or short circuits that may occur between the sensor itself or the sensor measurement system. Till exempel, transformers used in power distribution stations are surrounded by high voltage electric fields, and the electrical insulation of fluorescent fiber temperature sensors can ensure their normal operation and accurate temperature measurement in such environments.

Strong anti-interference ability:

During the operation of transformers, there are various complex electromagnetic interference sources inside, such as strong magnetic fields. Fluorescent fiber optic sensors use optical signals for detection and measurement, which have the characteristic of not being affected by electromagnetic interference. Därför, in this strong electromagnetic interference environment, it can accurately measure temperature without deviation caused by the electromagnetic field fluctuations of the transformer itself or external electromagnetic fields. Compared to traditional electronic sensors such as thermocouples, which are susceptible to electromagnetic interference and may experience measurement errors or signal fluctuations, fluorescent fiber optic sensors have significant advantages.

Shortcomings of Distributed Fiber, Fiber Bragg Galler, and Gallium Arsenide Fiber in Transformer Temperature Monitoring

Shortcomings of Distributed Fiber Optic:

In terms of equipment and cost: Distributed fiber optic temperature sensors based on Rayleigh scattering, Raman scattering, or Brillouin scattering principles require special measuring devices to detect weak scattered light signals. The equipment is complex and the overall cost is relatively high. For large-scale deployment in transformer temperature monitoring, both capital investment costs and equipment maintenance costs need to be considered, such as the need for professional personnel to maintain the equipment for detecting scattered light signals and the continuous debugging of some optical equipment components in case of possible failures in the future.

Accuracy and external factors: Its spatial resolution is relatively limited, which may result in the inability to meet the temperature measurement requirements of overly fine nodes in devices such as transformers, where the internal space is not infinite and high precision temperature monitoring is required. Ytterligare, although the measurement is based on the principle of optical scattering, optical fibers are easily affected by external pressure and other factors. Till exempel, if there are vibrations inside a transformer or if the optical fiber is compressed during installation, although the temperature does not change, these interferences may be mistakenly detected as temperature changes, resulting in measurement errors.

Shortcomings of Fiber Bragg Grating:

Structural fragility: Fiber Bragg grating temperature sensors require the fabrication of gratings on optical fibers. Fiber Bragg gratings are easily damaged in daily work or installation due to potential impact forces, as well as in the complex stress environment of transformers. Once the grating structure is damaged, accurate temperature measurement cannot be achieved. Till exempel, during the operation of a large capacity transformer, the strong impact force generated by its own vibration and possible sudden short circuits can damage the grating.

Environmental sensitivity: Humidity can affect the performance of fiber Bragg gratings. Till exempel, if the humidity around the transformer is high or exceeds the standard under certain special conditions, it is easy to change the optical characteristics of the fiber Bragg grating, resulting in measurement drift and other errors. Dessutom, due to the manufacturing process of gratings, the sensor cost is relatively high, which is also a limiting factor in the large-scale application of transformer temperature monitoring scenarios.

Shortcomings of Gallium Arsenide Fiber:

Optical path and calibration issues: When using gallium arsenide fiber optic sensors to measure transformer temperature, the optical path is a sensitive issue. If the layout of the circuit needs to be changed due to work or if the sensor needs to be re soldered, the optical path must be recalibrated to ensure measurement accuracy, which is a complex and tedious process. Especially in the working environment of transformers, the interior is a relatively enclosed and limited space environment, making optical path calibration very inconvenient.

Limitations of sensor networking: A single optical fiber can only connect to one gallium arsenide sensor, and cannot achieve multi-point networking measurement by connecting multiple sensors in series with a single optical fiber like fiber Bragg grating sensors. For synchronous temperature measurement of multiple positions inside the transformer, more separate fiber optic setups are required, which is disadvantageous in terms of layout and cost.

Case study of the effectiveness of fluorescent fiber in practical applications

Power equipment monitoring:

In terms of temperature monitoring of switchgear: The heating situation in the busbars and contacts of switchgear is complex, but fluorescent fiber optic sensors can have great potential and can be effectively applied to switchgear temperature monitoring. After installing the fiber optic fluorescence sensor at a critical location inside the switchgear, technicians can utilize the distributed measurement capability of the fiber optic sensor to achieve simultaneous monitoring of multiple temperature points inside the switchgear. The conductivity and electromagnetic field environment generated by internal electrical components during the measurement process did not interfere with the measurement results, and the sensor operated stably. By measuring and analyzing the changes in fluorescence signals, the real-time temperature of each monitoring point was successfully calculated. And the operation and maintenance personnel have set a temperature threshold. When the set value is exceeded, the system will promptly issue an alarm message to remind the operation and maintenance personnel to conduct detailed inspections and maintenance. This allows for a comprehensive understanding of the temperature distribution inside the switchgear, effectively preventing potential accidents such as insulation material aging and poor contact caused by overheating. It maximizes the normal and stable operation of the switchgear, thereby improving the reliability of power supply in the power system.

In terms of transformer temperature monitoring, the practical application of fiber optic fluorescence sensors in transformer temperature monitoring is similar to that of switchgear. Although the internal structure of a transformer is much more complex than that of a switchgear, with numerous components such as windings, järnkärnor, oil tanks, and pipelines, temperature monitoring can be effectively addressed by properly placing sensors in these areas. By installing fiber optic fluorescence sensors in transformer windings, it is possible to monitor the heat generated by coil resistance, iron loss, copper loss, and other losses when current passes through the windings; Installing sensors at the iron core can promptly detect temperature increases caused by hysteresis and eddy current losses; Installing sensors on the fuel tank wall and heat dissipation pipeline can monitor the heat dissipation status of the transformer. After installing fiber optic fluorescence sensors in these key areas, real-time monitoring of temperature changes in each part can be achieved and temperature signals can be transmitted remotely to the control center in a timely manner. Till exempel, once the temperature exceeds the set normal range, the on duty personnel can receive a warning and take corresponding measures, such as adjusting the load, repairing the cooling system, etc., to avoid the problem of rapid aging of the insulation material inside the transformer due to overheating and damage to the transformer. Throughout the entire operation process, the fiber optic fluorescence sensor demonstrates advantages such as high precision, strong anti-interference ability, and multi-point measurement.

Temperature monitoring in industrial microwave environment (derived from other scenarios):

In some scenarios involving industrial microwave equipment, such as microwave processing, vulcanization processes, microwave digestion extractors, disinfection/drying equipment, there is also a need for temperature monitoring. Microwaves have strong electromagnetic fields, and the temperature distribution inside the device is also uneven. Fluorescent fiber optic temperature sensors can adapt to high voltage, strong electromagnetic field environments inside microwave equipment and accurately measure multi-point temperatures without electromagnetic interference in this scenario. Till exempel, in food microwave processing, by reasonably arranging fiber optic fluorescence sensors in the processing chamber, the temperature trend during the processing can be accurately controlled to ensure the quality of food processing; In the vulcanization process, temperature monitoring can be carried out at multiple positions of the vulcanization mold through sensors to improve the quality of the vulcanized products. Because it is not affected by microwave electromagnetic field interference and has outstanding superiority, it has gradually been applied in temperature monitoring in other high-voltage and electromagnetic interference scenarios such as explosion-proof industrial environments and high-end scientific research in aviation and ships.

How to choose a suitable fluorescent fiber optic temperature sensor for transformers

Consideration of environmental factors for transformers:

Temperature range adaptability: It is necessary to clarify the oil temperature during normal operation of transformers and the possible extremely high temperatures that may occur during faults. Different fiber optic fluorescent temperature sensors have different temperature measurement ranges. If the operating temperature range of transformers fluctuates between -40 ℃ and 150 °C, it is necessary to choose a fluorescent fiber optic temperature sensor that can operate with high precision within this range or even wider range. Till exempel, some sensors may be suitable for a range of -30 ℃ to 120 °C, which may not meet the conditions.

Electromagnetic compatibility: Given the strong electromagnetic field inside the transformer, it is necessary to ensure that the selected fluorescent fiber temperature sensor can operate stably under electromagnetic fields ranging from low to high frequencies, without any signal acquisition errors or deviations.

Space layout and installation feasibility: The size of the fiber optic probe and the shape of the sensor need to be selected based on the internal space structure of the transformer. If the internal space of the transformer is compact and narrow, sensors with extremely small fiber optic probe sizes need to be selected in order to be installed smoothly in the designated location; Ytterligare, the rationality of fiber optic wiring needs to be comprehensively considered. If a distributed measurement scheme is adopted, the fiber optic wiring should not hinder the normal oil circulation inside the transformer and the normal operation of electrical components.

Related technical requirements for transformers:

Accuracy requirement: For some measurement scenarios that require extremely high accuracy of transformer winding hot spot temperature, such as high load transformers or ultra-high voltage transformers, if the winding hot spot temperature is accurate to 0.1 ℃ or even smaller error accuracy, it is necessary to choose a fluorescent fiber temperature sensor with higher measurement accuracy. The accuracy level of the sensor can be referred to and the data analysis obtained from actual experiments can be used as a reference. Till exempel, some high-end configurations have been tested in the laboratory under the same conditions, and sensors with an accuracy of ± 0.05 ℃ are more in line with the requirements.

Response speed requirement: If it is a situation that requires quick response to transformer faults or abnormal temperature changes, such as the need to quickly cut off switches or give protection device action instructions, the fluorescent fiber temperature sensor is required to have extremely fast response speed, be able to measure temperature and provide feedback signals in a short time. The response time can be the time from being affected by temperature changes to outputting recognizable change signals. I allmänhet, a response speed of less than 1 second is a good choice in many transformer protection scenarios.

Lifetime requirement: The transformer has a long service life, and it is expected that the selected fluorescent fiber temperature sensor will match it and work stably for a long time. It is necessary to investigate the stability of the fluorescent materials used in the sensors. Till exempel, some sensors use new rare earth fluorescent materials that are more stable than traditional materials in long-term high temperature, high magnetic field environments. The corresponding sensor life may be as long as 10-20 years or even longer. When selecting, such sensors are suitable for transformer installation scenarios that do not require frequent sensor replacement.

Cost benefit balance:

Purchase cost: The price of fluorescent fiber optic temperature sensors varies depending on the brand, production process, and performance indicators. Under the basic conditions of transformer temperature measurement, it is possible to compare the prices of sensors provided by multiple suppliers to avoid excessive purchase costs. Till exempel, the price of high-precision sensors from some imported brands in the market may be 2-3 times higher than that of domestic ordinary models. Emellertid, if ordinary models can meet the temperature measurement accuracy requirements of transformers, then low-priced products can be prioritized.

Maintenance cost: Sensors require maintenance and even replacement of parts during use. If sensors require special maintenance equipment or high environmental conditions, it will increase maintenance costs. Till exempel, some sensors use special gases to ensure stable fiber optic interface environments, which requires the purchase of corresponding gas generators and specialized maintenance of the system’s gas supply pipelines. Choosing sensors that do not require these special maintenance conditions can save costs.

Long term benefits: It involves the long-term stable operation benefits of transformers. If the temperature in winter and summer leads to different operating efficiencies of transformers, including sensors, accurate monitoring of transformer temperature can ensure that it can operate at its optimal state in different seasons and under different loads. This can reduce the overall economic losses caused by transformer failures or inefficient operation. I det här fallet, investing in reliable and durable sensors in the early stage is cost-effective in the long run.

INNO fiberoptiska temperatursensorer ,System för temperaturövervakning.

INNO fiberoptiska temperatursensorer ,System för temperaturövervakning.