Product Introduction of Distributed Fiber Optic Cable Temperature Measurement System:

Why do cables need to monitor temperature?

During the operation of power cables, the conductor, insulation layer, and metal shielding layer will be damaged, causing the cable to heat up and increasing the working temperature of each part. Excessive temperature can affect the insulation performance of the insulation material, cause insulation aging, shorten the service life of the cable, and in serious cases, lead to fire and power outage accidents. Based on the principle of Raman scattering effect, Fuzhou Yinuo Technology has developed a technology for installing distributed fiber optic temperature measurement in power cables, which can achieve full monitoring of cable temperature. It has the ability to resist electromagnetic interference, continuously measure the temperature points of the fiber optic cable along each point, timely detect local temperature anomalies, analyze insulation problems of the line, and prevent cable fires, ensuring the continuous and safe operation of the cable.

Characteristics of Distributed Fiber Optic Temperature Measurement System

Fully distributed: DTS distributed fiber optic temperature measurement can detect the complete distributed temperature along the entire fiber optic line in seconds without any omissions.

Long distance monitoring: The distributed optical fiber temperature measurement system of optoelectronics can monitor a distance of up to 30KM, and can customize longer distance temperature measurements.

Strong anti-interference: The temperature measuring optical fiber is composed of quartz, electrically insulated, and is not affected by any electromagnetic interference or emits electromagnetic waves, especially suitable for various complex and strong electrical environments.

Intrinsic safety: The temperature sensing element is a temperature measuring optical fiber, and the average power of the optical signal transmitted internally is at the micro watt level; Intrinsic safety.

Accurate positioning: The positioning accuracy reaches ± 1M.

Quick response: High sensitivity, quick response, and short single channel scanning time.

Easy installation: The analyzer is easy to install and has flexible layout.

Function of distributed fiber optic cable temperature measurement system

Alarm functions: constant temperature alarm, regional differential temperature alarm, rapid temperature rise alarm, fiber breakage alarm, device abnormality alarm, ndi zina;

Visual display function: Display the entire process zoning map, temperature distribution curve, and temperature variation curve over time at key monitoring points;

Query function: Query, display, and print historical data; Can directly query device information, operating parameters, statistical information, ndi zina. on the system diagram;

Analysis function: Display historical trends, evaluate future trends, and provide maintenance reference information;

TCP/IP access: Multiple controller signals can be analyzed and processed on a single PC, making the system powerful and efficient;

Multi system networking function: The system adopts network interfaces for data communication and has good compatibility, which can be easily extended to multiple hosts for simultaneous monitoring;

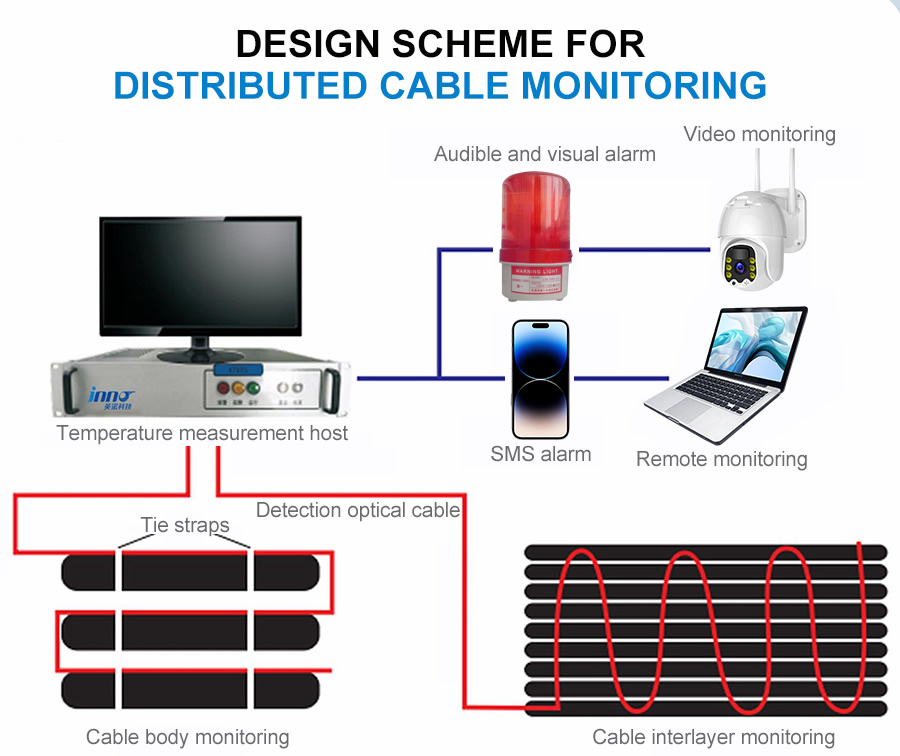

Temperature sensing fiber optic temperature measurement laying scheme

The laying method of temperature sensing optical fibers in cable interlayer and cable body

Temperature monitoring is required for each cable. The cable is fixed using surface mounted (external) optical cables. The laying of optical cables is fixed with optical cable fixing parts (insulation ties) to tightly bond the optical cable with the outer surface of the cable.

INNO CHIKWANGWANI chamawonedwe kutentha masensa ,machitidwe oyang'anira kutentha.

INNO CHIKWANGWANI chamawonedwe kutentha masensa ,machitidwe oyang'anira kutentha.