The measurement range specified in the “Трансформаторын электрон температур хянагч” (JB/T7631-2016), which uses Pt100 as the traditional temperature sensor, зөвхөн 1000 В-оос доош хүчдэлээр хязгаарлагдах боломжтой, and this sensor is made of metal material, which poses a safety hazard. Тиймээс, temperature sensor probes and leads for measuring transformer winding temperature have higher requirements.

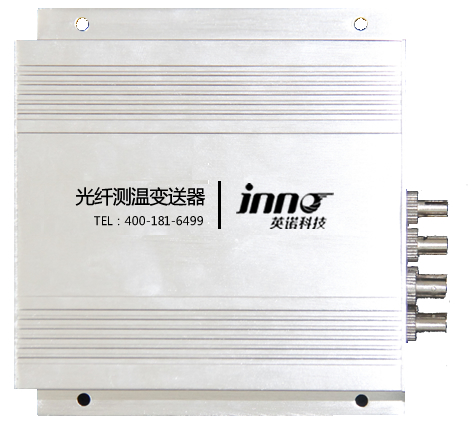

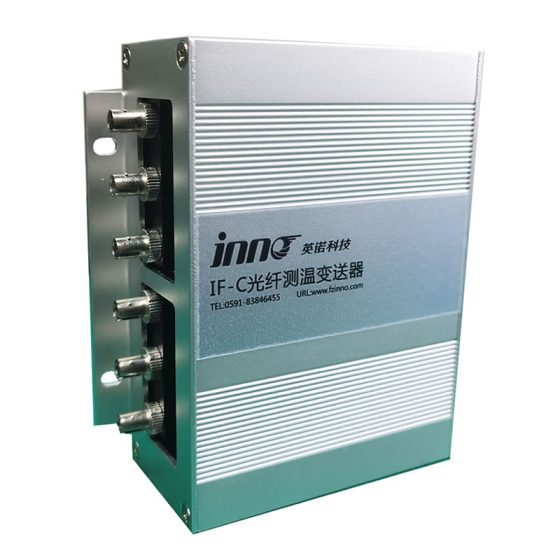

The fiber optic temperature measurement system for dry-type transformers uses a fluorescent fiber optic temperature sensor independently developed by Fuzhou INNO Technology as the temperature sensing element. Энэхүү температур мэдрэгч элемент нь цахилгаан соронзон хөндлөнгийн нөлөөнд тэсвэртэй, өндөр хүчдэлд тэсвэртэй (1000.4м-ийн зайд KV/fiber). Fluorescent fiber optic temperature measurement completely solves potential safety hazards from the source of temperature measurement and improves the safety level of transformers. The fluorescent fiber optic temperature measurement system for dry-type transformers aims to achieve isolation and shielding from external electrical interference signals in the operating environment of dry-type transformers, including power supply, signal input, signal output, and temperature control box casing. No metallic substances, дотоод аюулгүй байдал. Чичиргээний хариуд, тоос, moisture, oil and other on-site working environments, multi-layer protective measures are taken to ensure that the fiber optic temperature controller has good electromagnetic compatibility, ensuring stable and reliable operation.

Our company has actual application cases of fiber optic temperature measurement systems for dry-type transformers, which can be directly put into use.

The Function of Fluorescent Fiber Optic Temperature Sensor for Dry Transformer

Real time monitoring of transformer winding “hot spot” temperature

Assessable transformer operation status to enhance system reliability.

Real time monitoring of temperature information in transformer operation status

Can timely and effectively control loads, optimize transformer load operation configuration.

Timely monitoring of alarm information

During peak load operation, it can prevent unplanned and sudden faults caused by transformer overheating.

Long term online monitoring of transformer temperature trends

Can construct a transformer temperature change trend file to achieve pre management and risk prediction.

Provide dynamic, real-time, secure, and reliable information

The cooling system can be started in a timely manner to extend the service life of the transformer.

| basic function | 1. Three winding temperature measurement; Automatic/manual start/stop of cooling fan; Temperature display value compensation function for each channel

2. Хар хайрцагны функцээр хангана, which can record the temperature data of the last power outage and the highest historical temperature; 3. Digital tube display; 4. Трансформаторын хаалганы кабинетийг нээх цэгийн дохиоллын функцээр хангана; 5. Хангах 1 set of over temperature alarm contacts (1 normally open, 1 normally closed); 6. Хангах 1 set of over temperature trip contacts (1 normally open, 1 normally closed); 7. Хангах 1 set of fan remote transmission contacts (1 normally open, 1 normally closed); 8. Хангах 1 set of temperature controller fault alarm contacts (1 normally open, 1 normally closed); |

| Customized features | 1. Хангах 1 iron core temperature measurement and 2 iron core over temperature alarm contacts (1 normally open, 1 normally closed) (Би ажилладаг);

2. RS485 холбооны функцээр хангана, communication with time markers, capable of receiving time synchronization, MODBUS-RTU protocol (F функц); 3. Сэнсний алдаа оношлох функц, сэнсний эвдрэлийн дохиоллын контактыг хангах (L функц); 4. Хангах 4 бие даасан 4-20мА аналог гүйдлийн гаралтын функцууд (E функц); 5. Provide temperature measurement and control for the entire computer room environment; (G function) 6. Ороомгийн температурын өсөлтийн хурд болон төмрийн үндсэн температурын өсөлтийн хурдны дохиоллын функц; 7. Харилцааны протокол нь Profibus гэх мэт аргуудыг хэрэглэж болно, IEC60870-5-103, Ethernet холболт, гэх мэт; |

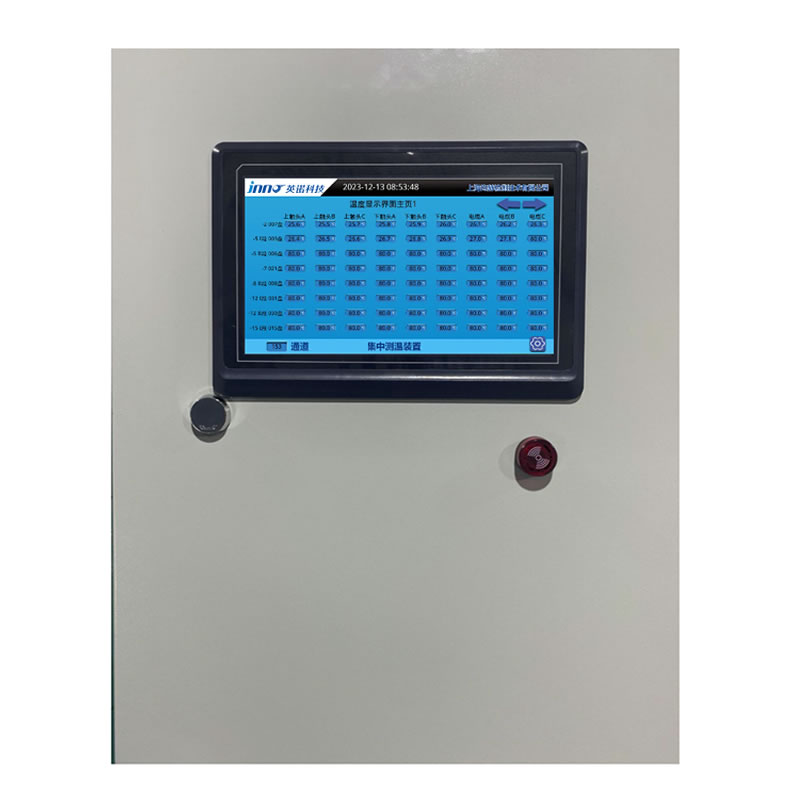

On site installation case of fiber optic temperature measurement device for dry-type transformer winding

|

|

|

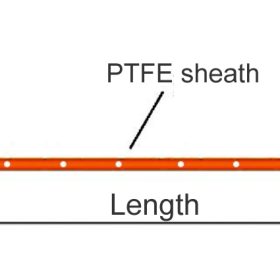

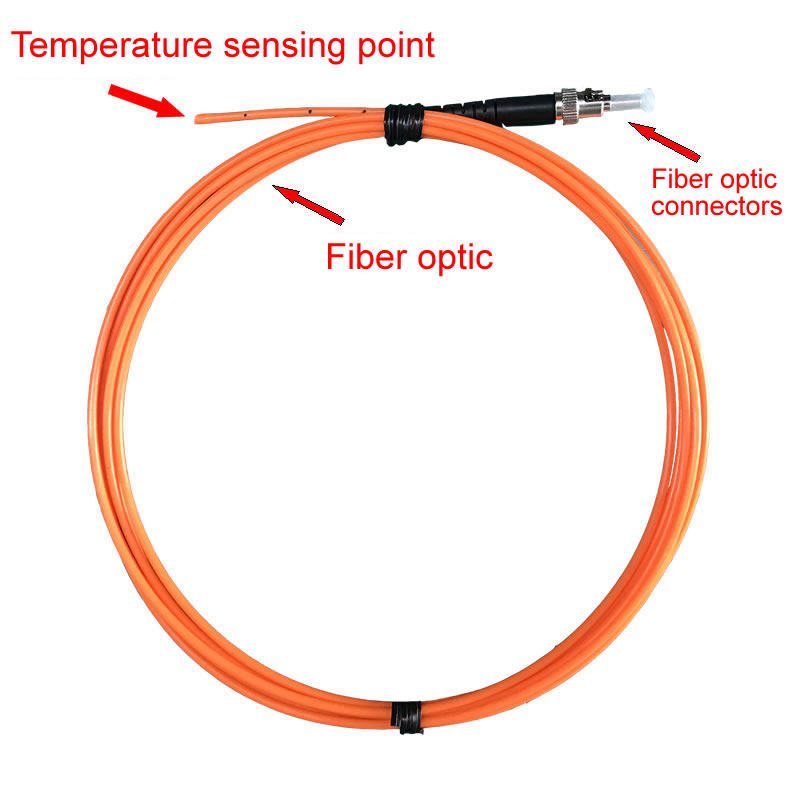

The advantages of fluorescent fiber optic temperature sensors

Fluorescent temperature sensors belong to all optical measurement devices

Only optical signals without electrical signals are true passive probes.

High insulation and voltage resistance

The fluorescent fiber optic temperature sensor can withstand a power frequency voltage of 100kV.

Fluorescent optical fibers are inherently immune to electromagnetic interference

The accuracy of detection and the stability of data transmission are completely unaffected.

Strong anti pollution flashover ability

The fluorescent fiber optic sensor is covered with a jacket with strong stain resistance to ensure the safety of the system.Temperature sensitive materials have high reliability

The temperature sensing material of the temperature sensor is rare earth material, which has a long-term stability and has been successfully applied in equipment monitoring for over 30 years of service life.Accurate positioning measurement

The temperature sensing probe has a small volume and can accurately locate the installation position.

Temperature measurement cycle is less than, with high real-time performance

The temperature measurement cycle is less than 1 second, which can fully ensure the timeliness of the alarm.

INNO шилэн кабелийн температур мэдрэгч ,температурын хяналтын систем.

INNO шилэн кабелийн температур мэдрэгч ,температурын хяналтын систем.