ഫൈബർ ഒപ്റ്റിക് താപനില സെൻസർ, ഇൻ്റലിജൻ്റ് മോണിറ്ററിംഗ് സിസ്റ്റം, ചൈനയിൽ വിതരണം ചെയ്ത ഫൈബർ ഒപ്റ്റിക് നിർമ്മാതാവ്

|

|

|

1、 Classification of temperature sensors

Temperature sensors are the core part of temperature measuring instruments, with a wide variety of types that can be classified according to different standards.

1.1 Classification by measurement method

Contact temperature sensor: This type of sensor requires direct contact with the object being measured to obtain temperature information. Common contact temperature sensors include thermocouples and thermistors. Thermocouples use the thermoelectric potential difference between two different metals to measure temperature. For example, in some industrial furnaces, thermocouples are directly inserted into the furnace to come into contact with high-temperature objects, and the temperature value is obtained through the thermoelectric potential difference; Thermistor is a sensor whose resistance changes with temperature, and its resistance has a specific functional relationship with temperature. It is commonly used in temperature monitoring and other fields of electronic devices.

Non contact temperature sensor: This type of sensor typically uses infrared radiation to measure the temperature of an object, without the need for direct contact with the object. Infrared temperature sensors are representative of this, which use the infrared radiation emitted by objects to measure their temperature. For example, when measuring the surface temperature of a high-temperature furnace, there is no need to touch the furnace, and temperature readings can be obtained by receiving its infrared radiation. This method is suitable for measuring the surface temperature of moving objects, small targets, and objects with small heat capacity or rapid temperature changes (transients), and can also be used to measure the temperature distribution of temperature fields.

1.2 Classification by Sensor Material and Electronic Component Characteristics/

Thermocouple: Based on the principle of thermoelectric effect, it uses the thermoelectric potential difference between two different metals to measure temperature. Thermocouples made of different materials are suitable for different temperature ranges. For example, K-type thermocouples can measure temperatures ranging from -200 ℃ to 1300 ℃, and are commonly used in industry for temperature measurement in high-temperature environments, such as temperature monitoring in steel smelting processes.

Resistance Temperature Detector (RTD): measures temperature based on the principle of resistance changing with temperature. Generally speaking, RTDs are more linear than thermocouples, and their resistance increases with temperature. Common RTDs include platinum resistors (Pt100, Pt10, മുതലായവ), among which Pt100 has a resistance value of 100 ohms at 0 ℃ and has high accuracy. It is commonly used for precise temperature measurement in laboratories and industries.

IC temperature sensor (integrated temperature sensor): Integrating temperature sensing elements, expansion circuits, compensation circuits, മുതലായവ. on a small chip, it has the advantages of good linearity, fast response, and standardized export. IC temperature sensors include two types: analog output and digital output. For example, AD590 is a current output temperature sensor from Analog Devices Inc. in the United States, with a supply voltage range of 3-30V, an output current of 223 μ A (-50 ℃) -423 μ A (150 ℃), and a sensitivity of 1 μ A/℃.

1.3 Classification by Working Principle

Expansion thermometer: made based on the principle of thermal expansion and contraction of objects, commonly used to measure temperature changes over a large range. For example, in common mercury thermometers, mercury expands when heated and rises in the capillary tube of the thermometer, indicating temperature based on the height of the mercury column.

Special type

Pressure and temperature sensor: a multifunctional sensor that can simultaneously measure temperature and pressure, used in some hydraulic systems, air conditioning and refrigeration systems that require simultaneous monitoring of temperature and pressure.

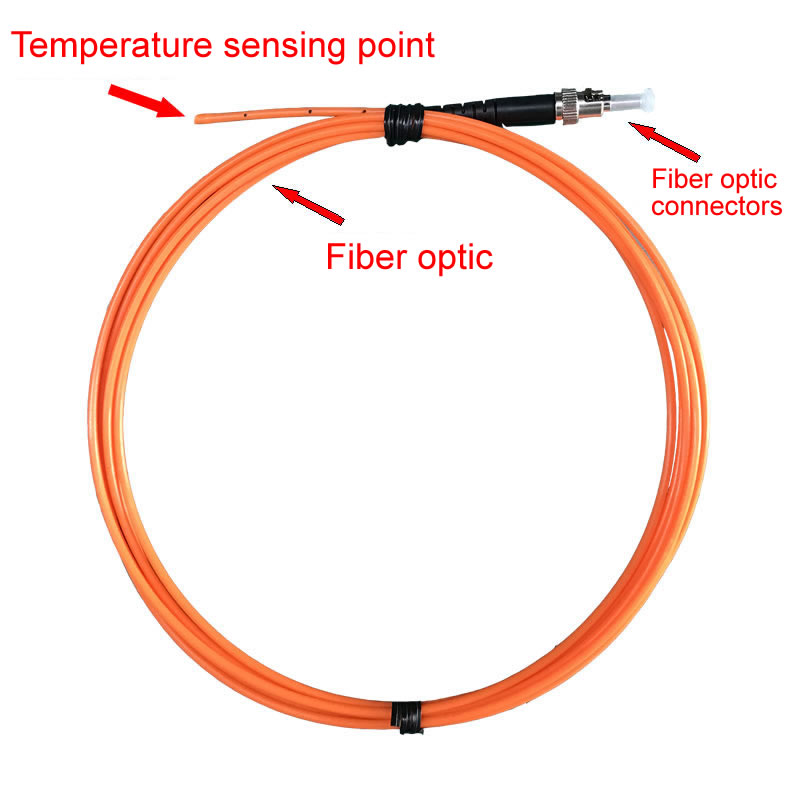

ഫൈബർ ഒപ്റ്റിക് താപനില സെൻസർ: uses the properties of the optical signal in the fiber optic to measure temperature. This includes fluorescent fiber temperature sensors, distributed fiber temperature sensors, fiber Bragg grating temperature sensors, മുതലായവ. Fiber optic temperature sensors have the advantages of high sensitivity, ചെറിയ വലിപ്പം, നേരിയ ഭാരം, easy bending, no electromagnetic interference, no electromagnetic interference, and good corrosion resistance. They are particularly suitable for temperature detection in harsh environments such as flammable, സ്ഫോടനാത്മകമായ, narrow spaces, and highly corrosive gases, liquids, and radiation pollution.

Logic output temperature sensor: Set a temperature range, and once the temperature exceeds the specified range, an alarm signal will be issued to turn on or off fans, air conditioners, heaters, or other control devices. For example, in some computer server rooms, if the temperature exceeds the set range, the logic output temperature sensor will trigger the air conditioning to turn on or off.

2、 യുടെ സവിശേഷതകൾ Fluorescent Fiber Optic Temperature Sensor

Fluorescent fiber optic temperature sensor is a sensor that uses fluorescent materials to undergo changes in fluorescence intensity or wavelength under temperature changes, and transmits signals through optical fibers to achieve temperature detection.

High precision: Fluorescent materials are particularly sensitive to temperature changes, making fluorescent fiber temperature sensors have high measurement accuracy. Because small changes in temperature can cause significant changes in fluorescence intensity or wavelength, accurate temperature values can be obtained by precisely measuring these changes. For example, in the field of medical diagnosis, fluorescent fiber optic temperature sensors can provide more accurate measurement results than traditional thermometers for detecting subtle changes in human body temperature.

Quick response: able to quickly respond to temperature changes, monitor temperature changes in real time, and respond immediately. This is very important in some situations where real-time temperature monitoring is required, such as in energy management systems, for temperature monitoring of power equipment. Once the equipment temperature rises abnormally, sensors can quickly provide feedback information to take timely measures.

High voltage resistance: Fluorescent fiber optic temperature measurement products have high voltage resistance, with a voltage resistance greater than 100KV. This allows it to directly measure temperature in high voltage environments. For example, in the temperature monitoring of equipment in ultra-high voltage substations, when facing high voltage environments exceeding 100KV, the end of the fluorescent fiber can make zero distance contact with the equipment for temperature measurement without being affected by high voltage, ensuring the normal operation of measurement work and providing important temperature data support for the safe operation of power equipment.

Strong anti-interference ability: Traditional temperature sensors can be affected by interference signals, while fluorescent fiber temperature sensors are not affected by interference signals and can work normally in complex electromagnetic environments. In environments with strong electromagnetic interference, such as near substations or large motor equipment, fluorescent fiber optic temperature sensors can stably measure temperature without measurement errors caused by electromagnetic interference like traditional electronic temperature sensors.

Long term stability: Fluorescent materials have strong durability and stability, and sensors can maintain high performance stability during long-term use. This means that in long-term temperature monitoring tasks, such as long-term temperature monitoring of large infrastructure such as bridges and dams, there is no need to frequently replace sensors or calibrate them.

Wide range of applicable environmental temperatures: Suitable for a wide range of environmental temperatures, from low to minus Baidu to high to several hundred degrees. Whether it is temperature monitoring of scientific research equipment in the extremely cold Arctic region or temperature measurement near high-temperature industrial furnaces, fluorescent fiber optic temperature sensors can work normally.

Flexibility and Scalability: Sensor fluorescent materials can be selected and designed according to actual needs to meet various specific application areas. Different fluorescent materials have different temperature fluorescence characteristics, and the most suitable fluorescent material can be selected to construct sensors according to specific application scenarios, such as biomedical research, industrial process monitoring, മുതലായവ. The number or range of monitoring points can be expanded as needed.

3、 The principle of distributed fiber optic temperature sensor

Distributed fiber optic temperature sensor is a sensor that uses unique distributed fiber optic detection technology to measure or monitor the spatial distribution and temporal information along the fiber optic transmission path.

Principles based on scattering effects

Rayleigh scattering: When light is transmitted in an optical fiber, Rayleigh scattering occurs due to the microscopic non-uniformity inside the fiber, such as small changes in density, രചന, മുതലായവ. The intensity of Rayleigh scattering light is related to temperature, and temperature changes can cause changes in the microstructure of optical fiber materials, resulting in changes in the intensity of Rayleigh scattering light. എന്നിരുന്നാലും, temperature measurement based solely on Rayleigh scattering has relatively low sensitivity, and in practical applications, it is often necessary to combine other scattering effects to improve measurement accuracy.

Raman scattering: This is a commonly used scattering effect in distributed fiber optic temperature sensors. Raman scattering light is divided into Stokes light and anti Stokes light, and their intensity ratio has a specific functional relationship with temperature. The laser transmitted in the fiber will interact with the molecules in the fiber to produce Raman scattering, and temperature changes will affect the vibrational energy levels of the molecules, thereby changing the intensity ratio of Stokes light and anti Stokes light. By measuring this intensity ratio, the temperature value can be calculated. For example, in some long-distance oil pipeline temperature monitoring, distributed fiber optic temperature sensors based on Raman scattering can be used to lay optical fibers along the pipeline and monitor the temperature at different positions of the pipeline in real time, preventing safety hazards caused by high or low oil temperature.

ബ്രില്ലൂയിൻ ചിതറിക്കൽ: The frequency of Brillouin scattering light changes with temperature and strain. In distributed fiber optic temperature sensors, temperature information is obtained by measuring the frequency drift of Brillouin scattering light. Brillouin scattering is sensitive to both temperature and strain, and in practical applications, special techniques are needed to distinguish the effects of temperature and strain, such as using special fiber structures or measurement methods.

Application of Optical Time Domain Reflectometry (ഒടിഡിആർ) Technology

Measurement principle: OTDR technology is an essential equipment for fault location and diagnosis in fiber optic communication, and also plays an important role in distributed fiber optic temperature sensors. It injects a light pulse into the fiber and detects the intensity of backscattered light in the fiber over time (distance). Due to temperature changes affecting the scattering characteristics in optical fibers, the intensity of backscattered light changes. By analyzing the distribution of backscattered light intensity, temperature distribution information along the length direction of the optical fiber can be obtained.

Spatial resolution: The spatial resolution of OTDR systems is generally on the order of meters. This means that it can distinguish temperature changes at a certain distance (in meters) on the fiber optic cable. For example, in the structural health monitoring of large bridges, by combining distributed fiber optic temperature sensors with OTDR technology, temperature changes in different parts of the bridge (every few meters) can be monitored, thereby determining whether there are abnormal thermal stresses in the bridge structure.

The relationship between measurement accuracy and spatial resolution: There is generally a mutual constraint between the measurement accuracy and spatial resolution of a system. സാധാരണയായി, to improve spatial resolution, a certain level of measurement accuracy may be sacrificed, and vice versa. This is because when improving spatial resolution, it is necessary to analyze the backscattered light signal more finely, which may be affected by factors such as noise, thereby reducing measurement accuracy.

4、 അപേക്ഷ ഫൈബർ ബ്രാഗ് ഗ്രേറ്റിംഗ് ടെമ്പറേച്ചർ സെൻസർ

Fiber Bragg grating temperature sensors have a wide range of applications in multiple fields.

Oil and gas exploration field

In the process of oil and gas extraction, the underground environment is complex, with harsh conditions such as high temperature, high pressure, and strong corrosion. Fiber Bragg grating temperature sensors can be installed on underground equipment or pipelines to monitor temperature changes in real time. For example, in the production string of an oil well, sensors can timely detect temperature increases caused by changes in formation temperature or frictional heating during the production process, providing a guarantee for safe production. അതിനിടയിൽ, by monitoring the temperature distribution, the mining process can be optimized and the mining efficiency can be improved.

Aerospace field

In the aerospace industry, there are extremely high requirements for the reliability and safety of equipment. The characteristics of fiber Bragg grating temperature sensors, such as small size, നേരിയ ഭാരം, fast response time, strong resistance to electromagnetic interference and corrosion, make them very suitable for temperature monitoring in aircraft engines, aviation electronic equipment, മുതലായവ. Installing fiber optic grating temperature sensors around high-temperature components such as combustion chambers and turbines in aircraft engines can monitor temperature in real-time and ensure that the engine operates within a safe temperature range. ഇതുകൂടാതെ, in the thermal protection system of spacecraft, sensors can monitor temperature changes, providing data support for the performance evaluation and optimization of thermal protection materials.

Medical diagnosis field

Accurate temperature control is crucial in medical devices such as magnetic resonance imaging (MRI) equipment, laser therapy equipment, മുതലായവ. Fiber Bragg grating temperature sensors can monitor the temperature of critical parts of equipment, preventing damage to patients and the equipment itself caused by overheating. അതേസമയത്ത്, in some minimally invasive medical surgeries, fiber optic grating temperature sensors can enter the human body through tiny fiber optic probes to monitor the temperature of tissues around the surgical site, providing guarantees for the safety and effectiveness of the surgery.

Industrial process control field

In various industrial production processes, such as chemical, metallurgical, and power industries, temperature is a key control parameter. Fiber Bragg grating temperature sensors can be used to monitor the temperature of equipment such as reaction vessels, furnaces, and motors. For example, in the chemical reaction kettle of chemical production, sensors can monitor the reaction temperature in real time to ensure that the reaction proceeds under optimal temperature conditions, improving product quality and production efficiency. In the power system, temperature monitoring of high-voltage equipment, cables, മുതലായവ. in substations can timely detect potential fault hazards and avoid power accidents.

5、 Comparison of Three Types of Fiber Optic Temperature Sensors

In terms of measurement principles

ഫ്ലൂറസെൻ്റ് ഫൈബർ ഒപ്റ്റിക് താപനില സെൻസർ: measures temperature based on the change in fluorescence intensity or wavelength of fluorescent materials under temperature changes. When fluorescent materials are affected by temperature changes, their fluorescence characteristics will also change. A typical fluorescent fiber optic temperature sensor includes a light source, optical fiber, fluorescent material, and a spectral analyzer. The light source generates excitation light of a certain wavelength, which is transmitted to the fluorescent material through an optical fiber. The fluorescent material absorbs the excitation light and emits a fluorescence signal with a specific wavelength, which is then transmitted back to the spectrometer for detection through the optical fiber. The temperature value can be determined by measuring the intensity or wavelength of the fluorescence signal.

Distributed fiber optic temperature sensor: mainly based on scattering effects in optical fibers (Rayleigh ചിതറിക്കൽ പോലുള്ളവ, Raman scattering, ബ്രില്ലൂയിൻ ചിതറിക്കൽ) and optical time domain reflectometry (ഒടിഡിആർ) technology to achieve temperature measurement. By injecting light pulses into the optical fiber, the intensity, frequency, and other characteristics of backscattered light can be detected as a function of time (distance). Since temperature affects these scattering characteristics, temperature distribution information along the length direction of the optical fiber can be obtained.

ഫൈബർ ബ്രാഗ് ഗ്രേറ്റിംഗ് ടെമ്പറേച്ചർ സെൻസർ: Utilizing the photosensitivity of fiber optic materials to form a spatial phase grating in the fiber core for temperature measurement. ഫൈബർ ബ്രാഗ് ഗ്രേറ്റിംഗ് (FBG) is a type of fiber with a periodically changing refractive index. When the temperature changes, the Bragg wavelength of the grating shifts, enabling temperature measurement.

In terms of performance characteristics

measurement accuracy

ഫ്ലൂറസെൻ്റ് ഫൈബർ ഒപ്റ്റിക് താപനില സെൻസർ: It has high measurement accuracy because fluorescent materials are very sensitive to temperature changes and can accurately reflect small temperature changes.

Distributed fiber optic temperature sensor: Its measurement accuracy is affected by various factors, such as the complexity of scattering effects and the resolution of OTDR technology. In practical applications, the accuracy of distributed fiber optic temperature sensors based on Raman scattering is generally around 1-2 ℃, but with the development of technology, the accuracy is also constantly improving.

ഫൈബർ ബ്രാഗ് ഗ്രേറ്റിംഗ് ടെമ്പറേച്ചർ സെൻസർ: High precision, for example, some fiber Bragg grating temperature sensors that use special packaging and measurement techniques can achieve an accuracy of 0.02 ℃.

response speed

ഫ്ലൂറസെൻ്റ് ഫൈബർ ഒപ്റ്റിക് താപനില സെൻസർ: With fast response speed, it can monitor temperature changes in real time and respond immediately, making it advantageous in situations where rapid temperature response is required.

Distributed fiber optic temperature sensor: The response speed depends on the emission frequency of the light pulse and the signal processing speed. Generally speaking, it can meet the temperature monitoring needs in most practical applications, but may be slightly slower compared to fluorescent fiber optic temperature sensors.

ഫൈബർ ബ്രാഗ് ഗ്രേറ്റിംഗ് ടെമ്പറേച്ചർ സെൻസർ: With fast response time, it can quickly sense temperature changes and output corresponding wavelength offset signals.

spatial resolution

Distributed fiber optic temperature sensor: It has unique distributed measurement capabilities and can measure temperature distribution along the length of the fiber optic cable. The spatial resolution is generally on the order of meters (when using OTDR technology), and some systems that use advanced technologies (such as OFDR) can achieve millimeter level spatial resolution.

ഫ്ലൂറസെൻ്റ് ഫൈബർ ഒപ്റ്റിക് താപനില സെൻസർ: Although it can achieve distributed measurement, it mainly focuses on temperature measurement at multiple discrete points, and its spatial resolution is not as good as that of distributed fiber optic temperature sensors, which can continuously measure temperature distribution along the fiber optic.

ഫൈബർ ബ്രാഗ് ഗ്രേറ്റിംഗ് ടെമ്പറേച്ചർ സെൻസർ: It usually measures the temperature at a specific location and does not have the continuous spatial resolution characteristics of distributed fiber optic temperature sensors.

Anti-interference ability

ഫ്ലൂറസെൻ്റ് ഫൈബർ ഒപ്റ്റിക് താപനില സെൻസർ: It is not affected by interference signals and can work normally in complex electromagnetic environments. This is because its measurement principle based on optical signals has a natural immunity to electromagnetic interference.

Distributed fiber optic temperature sensor: It also has good anti-interference ability because fiber optic itself is an insulator, and measurement is based on the optical signal in the fiber optic, which is not easily affected by external electromagnetic interference.

ഫൈബർ ബ്രാഗ് ഗ്രേറ്റിംഗ് ടെമ്പറേച്ചർ സെൻസർ: It has strong resistance to electromagnetic interference, and due to its optical properties based on grating structure for temperature measurement, it also has good resistance to interference such as chemical corrosion and vibration in the environment.

Applicable temperature range

ഫ്ലൂറസെൻ്റ് ഫൈബർ ഒപ്റ്റിക് താപനില സെൻസർ: suitable for a wide range of environmental temperatures, from as low as minus Baidu to as high as several hundred degrees Celsius, and can adapt to temperature measurement needs in various extreme temperature environments.

Distributed fiber optic temperature sensors: Different types of distributed fiber optic temperature sensors have different temperature ranges, but they can generally cover a wide temperature range, such as common industrial and environmental temperature ranges from -50 ℃ to 150 ℃.

ഫൈബർ ബ്രാഗ് ഗ്രേറ്റിംഗ് ടെമ്പറേച്ചർ സെൻസർ: It can work normally in both high and low temperature environments, for example, it can be used for temperature measurement range of -200 ℃ -800 ℃, depending on factors such as the material and packaging of the fiber Bragg grating.

In terms of application areas

ഫ്ലൂറസെൻ്റ് ഫൈബർ ഒപ്റ്റിക് താപനില സെൻസർ: widely used for real-time temperature monitoring and control in fields such as medical diagnosis and energy management. In the medical field, it can be used for precise measurement of human body temperature and monitoring of organ temperature inside the body; In terms of energy management, temperature monitoring of power equipment, thermal pipelines, മുതലായവ. can be carried out.

Distributed fiber optic temperature sensors: widely used in stress, strain, and temperature monitoring of large structures (such as pipelines, offshore oil platforms, oil wells, dams, embankments, bridges, കെട്ടിടങ്ങൾ, തുരങ്കങ്ങൾ, cables, മുതലായവ), leakage detection (liquid or natural gas pipelines, industrial processes, dams, tanks, മുതലായവ), transportation (ice detection on road surfaces, railway monitoring, മുതലായവ), safety systems (fire or overheating temperature detection, power cable monitoring, signal eavesdropping monitoring, garbage disposal station monitoring, landslide monitoring, മുതലായവ), fiber optic communication (fiber optic cable production online control, fiber optic cable maintenance, work cable strain monitoring, fiber optic impurity measurement, മുതലായവ), environmental measurement (thermal, ventilation, and air conditions, long-term temperature measurement of external oceans, forests, and outdoor places), മുതലായവ. The application.

ഫൈബർ ബ്രാഗ് ഗ്രേറ്റിംഗ് ടെമ്പറേച്ചർ സെൻസർ: It has been widely used in various environmental monitoring fields such as oil and gas exploration, ബഹിരാകാശം, medical diagnosis, and industrial process control. Used for temperature monitoring of downhole equipment and pipelines in the oil and gas industry; Temperature monitoring for aircraft engines, aviation electronic equipment, മുതലായവ. in the aerospace field; Used in the medical field for temperature control of medical equipment and temperature monitoring of surgical sites; Used in the industrial field for temperature monitoring of various equipment and production processes.

INNO ഫൈബർ ഒപ്റ്റിക് താപനില സെൻസറുകൾ ,താപനില നിരീക്ഷണ സംവിധാനങ്ങൾ.

INNO ഫൈബർ ഒപ്റ്റിക് താപനില സെൻസറുകൾ ,താപനില നിരീക്ഷണ സംവിധാനങ്ങൾ.