Сензор за температура со оптички влакна, Интелигентен систем за следење, Дистрибуиран производител на оптички влакна во Кина

|

|

|

The main methods for monitoring transformer temperature include traditional thermometer measurement, fluorescent fiber optic temperature measurement, distributed fiber optic temperature measurement, and fiber optic grating temperature measurement.

1、 Method of Transformer Temperature Monitoring

(1) Traditional thermometer measurement

Principle and Method

The traditional thermometer is a more direct way to measure the temperature of transformers. For example, in oil immersed transformers, a thermometer can be inserted into the oil surface of the transformer to monitor the temperature of the oil surface in real time, which is one of the main sensor methods of the temperature controller for oil immersed transformers. For temperature measurement of dry-type transformers, three or four PT100 sensors are used, mainly for measuring the temperature of windings or iron cores. This method is based on the principle of thermal expansion and contraction, in which the liquid (such as mercury or alcohol) or metal (such as bimetallic strips) in the thermometer changes volume or shape with temperature changes, thereby displaying the corresponding temperature value on the thermometer scale.

In practical applications, PT100 sensor is a common thermal resistance sensor, and its resistance value increases linearly with the increase of temperature. In transformer temperature monitoring, the resistance value of PT100 is measured, and the corresponding conversion circuit is used to convert the resistance value into a temperature value, thereby obtaining the temperature of the transformer winding or iron core. This type of sensor has high accuracy and good stability, which can meet the basic needs of transformer temperature monitoring.

limitations

The traditional thermometer measurement method has some limitations. For the temperature distribution inside the transformer, a single oil level thermometer can only reflect the overall oil temperature and cannot accurately obtain the hot spot temperature inside the winding. Згора на тоа, this contact measurement method may be subject to interference from the internal electromagnetic field of the transformer, which can affect the accuracy of the measurement. Покрај тоа, the installation position of the thermometer can also affect the measurement results. If the installation position is improper, it may not accurately reflect the true temperature condition of the transformer.

(2) Wireless temperature measurement solution

Principle and Method

In transformer temperature monitoring, wireless temperature measurement solutions are suitable for specific scenarios such as transformer joints, surface temperature monitoring, итн. Taking the Ankerui temperature measurement system as an example, when factors such as loose transformer nuts or small washer area cause high contact resistance at the connection port, resulting in temperature changes at the transformer inlet and outlet, a wireless temperature measurement solution can be used. By installing ATE400 at the inlet and outlet of the transformer and adsorbing ATE100M on the surface of the transformer, these devices can collect temperature data and then transmit the collected temperature data wirelessly to the ARTM Pn display terminal. This wireless transmission method avoids the trouble of wiring and has good adaptability to the complex external environment of transformers.

limitations

The wireless temperature measurement scheme also has certain limitations. Wireless signals may be subject to interference from the surrounding environment, such as electromagnetic interference, obstacles, итн., which can affect the stability and accuracy of signal transmission. Згора на тоа, wireless devices require battery power, and if the battery is low or faulty, it may cause interruptions in temperature data collection and transmission. Покрај тоа, the cost of wireless devices is relatively high, and for large-scale transformer temperature monitoring systems, the overall construction cost will increase.

(3) Fiber optic measurement system

Principle and Method

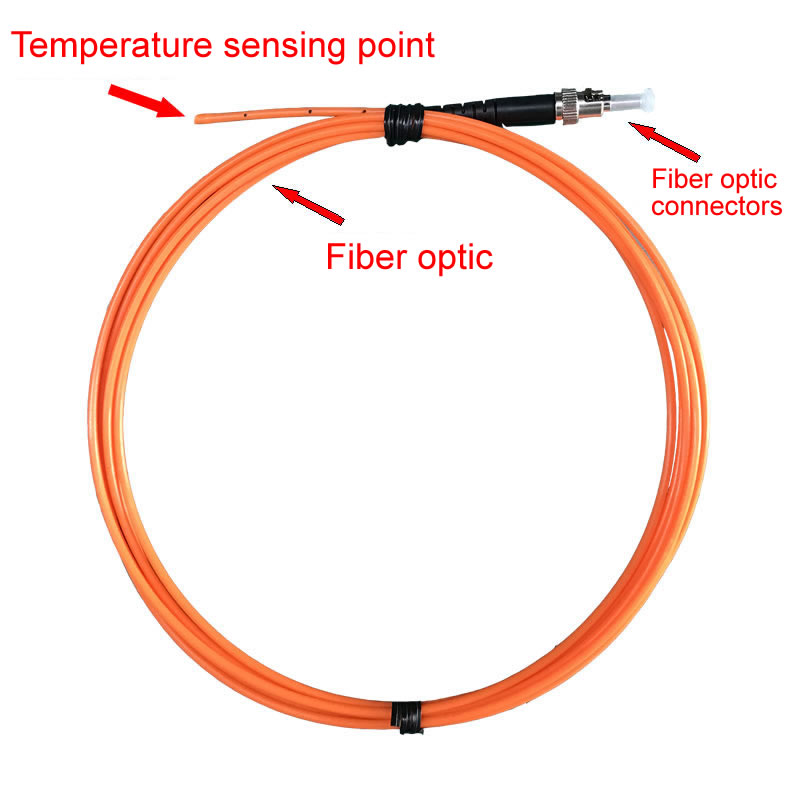

Fiber optic measurement systems have unique advantages in transformer temperature monitoring. The fiber measurement system based on Raman effect is one of them. In the production process of transformers, the fiber is encapsulated and laid along the winding, and the length of the fiber can reach 250m. The measurement principle is to use laser to irradiate short light pulses into the optical fiber, and the photons of the light pulses scatter on the molecules of the glass fiber. When the temperature rises, the wavelength of the backscattered photons will change, and this wavelength shift is proportional to the temperature difference. Затоа, reliable multi-point temperature measurement can be carried out on transformers. This method can achieve temperature monitoring of the entire winding area inside the transformer, clarifying the location and intensity of temperature rise.

There are also some fiber optic measurement systems based on other principles, such as fluorescent fiber optic temperature measurement systems, дистрибуирани системи за мерење на температурата со оптички влакна, and fiber optic grating temperature measurement systems, each with different working principles and characteristics, which will be introduced in detail in the following content.

advantage

Fiber optic measurement systems have many advantages compared to other measurement methods. Firstly, optical fibers have good insulation properties and can operate safely and reliably in transformer environments with high voltage and strong electromagnetic fields. Secondly, optical fiber itself is a passive component that does not generate electromagnetic interference and is not affected by external electromagnetic interference, ensuring the accuracy of measurement data. Покрај тоа, the fiber optic measurement system can achieve distributed measurement and obtain temperature information at different positions inside the transformer, which helps to comprehensively understand the temperature distribution of the transformer.

2、 Advantages of using fluorescent optical fiber for transformer temperature monitoring

(1) Strong anti-interference ability

Anti electromagnetic interference characteristics

Fluorescent optical fibers have excellent electromagnetic interference resistance in transformer temperature monitoring. In the operating environment of transformers, there is a strong electromagnetic field, and traditional electrical temperature measuring instruments are susceptible to electromagnetic interference, leading to a decrease in measurement accuracy or even temperature measurement failure. The fluorescence fiber optic temperature measurement system adopts fluorescence fiber optic temperature sensing technology, and the temperature hotspot of the fluorescence fiber optic temperature sensor used in its transmitter is not electrically connected to the measurement signal receiving part. This characteristic enables fluorescent optical fibers to operate normally in special environments such as high voltage and strong electromagnetic interference, without measurement errors caused by electromagnetic interference. It can measure the temperature of transformers with high precision and stability for a long time, and accurately monitor their temperature changes, whether they are oil immersed transformers or dry transformers.

Anti other interference

In addition to being resistant to electromagnetic interference, fluorescent optical fibers can be safely used in almost any environment without being affected by EMI (electromagnetic interference), RF (radio frequency interference), MRI (magnetic resonance imaging interference), microwave interference, immune electromagnetic interference, and microwave interference. For example, in some complex power equipment operating environments, there may be multiple sources of interference, such as radio equipment, radio frequency interference generated by other electrical equipment, итн. Fluorescent optical fibers can be used for temperature monitoring without being affected. This anti-interference ability makes the fluorescence fiber optic temperature measurement system widely applicable in complex electromagnetic environments such as substations.

(2) Intrinsic safety characteristics

Safety without electrical connections

In the fluorescence fiber optic temperature measurement system, due to the lack of electrical connection between the temperature hotspot and the measurement signal receiving part, this characteristic makes it inherently safe. In high-voltage equipment environments such as transformers, the absence of electrical connections avoids safety hazards caused by electrical faults, such as leakage and short circuits. Even in extreme situations such as transformer failures, such as short circuits causing arcs, fluorescent optical fibers will not be damaged or cause secondary accidents due to electrical connections, ensuring the safety of the monitoring system itself and the safety of the transformer equipment and surrounding environment.

Suitable for hazardous environments

This intrinsic safety feature makes the fluorescent fiber optic temperature measurement system suitable for various hazardous environments. For example, in oil immersed transformers, there is flammable transformer oil. If electrically connected temperature measuring equipment is used, once an electrical fault occurs and sparks are generated, it may cause a fire or even an explosion. The fluorescent fiber optic temperature measurement system, due to the lack of electrical connections, does not generate electrical sparks and can safely monitor temperature inside oil immersed transformers, greatly improving the safety of transformer operation.

(3) High precision and high stability

Accurate temperature measurement

The fluorescence fiber optic temperature measurement system can achieve accurate temperature measurement. Its probe adopts special materials and structural design, which can accurately sense temperature changes and convert them into measurable signals. For example, its fiber optic probe has no metallic material and is completely non-metallic in structure, while the fiber optic sensing probe is made of rare earth materials. The characteristics of this material and structure make fluorescent optical fibers highly sensitive to temperature changes, enabling precise measurement of temperature at different locations inside the transformer. Whether it is the temperature of the winding hotspot or other parts, high measurement accuracy can be achieved, meeting the accuracy requirements for transformer temperature monitoring.

Long term stable work

The fluorescence fiber optic temperature measurement system has the ability to operate stably for a long time. Due to its resistance to various external interference factors and the use of materials with good stability, temperature monitoring can be continuously and stably carried out during long-term transformer operation. Unlike some traditional temperature measuring devices, which may experience a decrease in measurement accuracy or equipment failure over time or changes in the environment. For example, in long-term operating substations, the fluorescent fiber optic temperature measurement system can work stably for many years, providing reliable temperature data for the safe operation of transformers.

(4) Probe performance advantages

Small diameter probes have strong applicability

The diameter of the fluorescent fiber probe can be made smaller, such as 2.5mm (smaller diameters can be customized). Small diameter probes have strong applicability in transformer temperature monitoring, especially in some limited space locations, such as the narrow space inside the transformer winding. Small probes can be installed and arranged more easily without causing significant impact on the original structure of the transformer. Meanwhile, a small diameter probe is also beneficial for improving measurement accuracy, as it can be closer to the measured area and reduce interference from the surrounding environment on the measurement results.

Advantages of probe materials

The materials used in fluorescent fiber optic probes have multiple advantages. If the probe has no metallic substance and is completely non-metallic in structure, this material characteristic makes the probe have good insulation performance and can work safely in high-voltage transformer environments. And the probe made of rare earth materials performs well in high temperature resistance, wear resistance, и други аспекти. During the operation of transformers, especially in high-temperature environments, the probe material can maintain stable performance and will not deform or be damaged due to high temperatures, thereby ensuring the accuracy and reliability of temperature measurement.

3、 Предности на Distributed Fiber Optic for Transformer Temperature Monitoring

(1) Distributed measurement capability

Continuous dynamic monitoring

The distributed fiber optic temperature measurement online monitoring system adopts advanced OTDR (Optical Time Domain Reflectance) technology and Raman scattering light’s sensitivity to temperature, which can detect temperature changes at different positions along the fiber optic cable and achieve truly distributed measurement. It can provide continuous dynamic monitoring of temperature change signals at every 0.5 meters point within a range of more than ten kilometers. This is very meaningful for transformer temperature monitoring, as the temperature distribution inside the transformer is not uniform and there may be local hotspots. Distributed optical fibers can accurately obtain temperature information from these different locations, thus comprehensively understanding the temperature field distribution inside the transformer. For example, in large transformers, temperature differences may occur in different parts of the winding due to different current densities and other reasons. Distributed optical fibers can monitor these temperature differences in detail, providing more comprehensive temperature data support for the safe operation of transformers.

Accurate positioning

Distributed optical fibers can not only measure temperature, but also accurately locate the location of temperature anomalies. Based on OTDR technology, the echo time of the scattered signal can be determined by using high-speed data acquisition to measure the corresponding fiber position of the scattered signal. When there is an abnormal temperature rise in a certain part of the transformer, the distributed fiber optic temperature measurement system can accurately indicate the location of the abnormal temperature, which helps to quickly locate the fault point and take timely measures for maintenance or adjustment. For example, when faults such as inter turn short circuits occur in transformer windings, causing local high temperatures, distributed optical fibers can quickly determine the specific location of the fault, greatly reducing the time for fault diagnosis.

(2) Adapt to multiple environments

Против електромагнетни пречки

The distributed fiber optic temperature measurement system has strong resistance to electromagnetic interference in transformer environments. During the operation of transformers, there is a strong electromagnetic field, and distributed optical fibers use optical signals for temperature measurement and transmission, without generating mutual electromagnetic interference with power cables. This enables it to operate stably and accurately in transformer environments with high voltage and strong electromagnetic interference. Distributed optical fibers can effectively monitor temperature in both substations and industrial environments, unaffected by electromagnetic fields.

Suitable for hazardous locations

The distributed fiber optic temperature measurement system is also suitable for hazardous areas such as flammable and explosive. Due to its use of optical signal transmission and the absence of hazardous factors such as electric sparks, temperature monitoring can be safely carried out in environments with flammable substances such as oil immersed transformers. Згора на тоа, distributed optical fibers have characteristics such as corrosion resistance, which can adapt to the possible chemical corrosion environment around transformers. For example, in some chemical enterprises, distributed optical fibers can work stably for a long time to ensure the temperature monitoring needs of transformers.

(3) Measurement performance advantages

High precision and high resolution

The distributed fiber optic temperature measurement system has high measurement accuracy and temperature resolution. Its typical temperature resolution reaches 0.5 ℃, temperature accuracy is 1 ℃, and spatial resolution can reach up to 0.5m. This high-precision and high-resolution feature enables it to accurately detect small temperature changes inside the transformer. For example, during normal operation of a transformer, although the overall temperature is relatively stable, there may be some small local temperature fluctuations. Distributed optical fibers can accurately measure these fluctuations and promptly detect potential safety hazards.

quick response

The response speed of this system is very fast, with a minimum measurement time of 3 seconds per measurement. This feature enables distributed optical fibers to capture changes in the internal temperature of transformers in a timely manner. When a sudden fault occurs in the transformer, causing a sharp rise in temperature, the distributed fiber optic temperature measurement system can quickly respond, obtain temperature change information in a short period of time, and issue an alarm signal. This rapid response capability helps to improve the safety of transformers and reduce the possibility of accidents caused by high temperatures.

(4) System flexibility and compatibility

Flexible alarm settings

The distributed fiber optic temperature measurement system has strong flexibility. It can set various temperature alarm values at any level, and has multiple alarm methods for differential fixed temperature. The alarm parameters can be set in different zones according to customer needs. For example, different alarm values can be set according to the actual temperature safety range at different operating stages or different parts of the transformer. For key parts such as windings, relatively low alarm temperature values can be set, while for parts such as transformer casings, relatively high alarm temperature values can be set, which can more accurately monitor and warn of the temperature condition of the transformer.

Good compatibility

The host of the distributed fiber optic temperature measurement system is an open communication protocol that provides a communication interface to connect with the workstation. It can be linked with other control devices such as PCs and fire alarm systems through RS232, RS485, built-in relays, RJ45, or other industrial protocols for sound and light alarms, with accurate and complete signal output. This compatibility enables the distributed fiber optic temperature measurement system to be easily integrated into existing transformer monitoring systems, working together with other devices to ensure the safe operation of transformers.

4、 Предности на Fiber Bragg Grating for Transformer Temperature Monitoring

(1) Good linear relationship and measurement accuracy

The linear relationship between reflection wavelength and temperature

Браг решетка со влакна (FBG) is a light sensing component made on optical fibers that only reflects specific wavelengths. The reflected wavelength has an excellent linear relationship with temperature. The determination coefficient of linear fitting between the reflection wavelength of fiber Bragg grating and temperature is relatively high, which makes it possible to accurately calculate the temperature change value by measuring the change in the reflection wavelength of fiber Bragg grating. In transformer temperature monitoring, this linear relationship can improve the accuracy of temperature measurement. For example, when the temperature of the transformer winding changes, fiber Bragg gratings can accurately reflect the increase or decrease in temperature based on the change in reflected wavelength, providing reliable data support for temperature monitoring of transformers.

Accurate measurement adapted to harsh environments

Fiber Bragg grating sensors are suitable for long-term monitoring in harsh environments. Inside the transformer, the environment is complex and there are factors such as high voltage and strong electromagnetic field. Сепак, due to its optical properties, fiber Bragg grating sensors are not affected by electromagnetic interference and can accurately measure temperature. And during the operation of transformers, they may be affected by various factors such as vibration and temperature fluctuations. Fiber Bragg grating sensors can maintain stable performance in such harsh environments and continuously and accurately monitor temperature changes.

(2) Reusability and multi-sensor series connection

Reusable features

Fiber Bragg grating sensors have the advantage of being reusable. Fiber Bragg grating sensors with different wavelengths can be engraved at different positions on the optical fiber, and each sensor is encoded with the reflected wavelength of the light when the fiber Bragg grating is engraved. This means that multiple fiber Bragg grating sensors can be integrated on a single optical fiber, and through wavelength division multiplexing technology, up to 20 fiber Bragg grating sensors can be connected in series on a single optical fiber. In transformer temperature monitoring, this reusability can achieve temperature monitoring of multiple parts of the transformer. For example, fiber Bragg grating sensors can be installed at different positions of the high-voltage winding and low-voltage winding of the transformer. These sensors can be connected through a single optical fiber to obtain temperature information from multiple positions, reducing the use of optical fibers and system complexity.

Efficient sensor networking

Based on the reusability of fiber Bragg gratings, efficient sensor networking topologies can be constructed. Multiple fiber Bragg grating sensors are connected in series on a single fiber optic cable for centralized management and data acquisition. Compared with other temperature measurement methods, this networking approach is more concise and efficient. In the transformer monitoring system, fiber Bragg grating sensors can be flexibly arranged according to the structure and temperature monitoring requirements of the transformer, and a suitable sensor network can be constructed to achieve comprehensive and efficient monitoring of the internal temperature of the transformer.

(3) Sensor performance advantages

Small size and lightweight

Fiber Bragg grating sensors have the characteristics of small size and light weight. This ensures that it will not have a significant impact on the structure of the transformer when installed inside. For example, in the narrow space of transformer windings, fiber Bragg grating sensors can be easily installed without changing the electrical and mechanical properties of the windings. Small size and lightweight sensors are also easy to embed in the transformer manufacturing process, which can better integrate with the transformer and achieve long-term and stable monitoring of transformer temperature.

Long term stability

Fiber Bragg grating sensors exhibit good stability during long-term operation. Due to its light based sensing principle, it is not affected by external electromagnetic interference, chemical corrosion, and other factors, and can operate continuously and stably throughout the operating life cycle of the transformer. In the long-term temperature monitoring process, there will be no performance degradation, measurement error increase or other problems, providing reliable guarantee for the temperature monitoring of transformers.

(4) Compatibility and Security

Compatibility with transformer oil

Fiber Bragg grating sensors have good compatibility with transformer oil. After relevant experimental evaluation, according to GB/T16927.1-19 “High Voltage Testing Techniques Part 1 General Test Requirements”, the oil test results of the oil sample before and after the test were qualified after being placed in an oil temperature of 105 ° C for 168 часови, and there was no cracking phenomenon in the fiber Bragg grating sensor and related materials. In practical applications, this means that fiber Bragg grating sensors can be safely installed inside oil immersed transformers, and will not have any impact on the performance of transformer oil due to long-term contact with transformer oil, nor will their performance decrease due to interaction with transformer oil, ensuring the normal operation of transformers.

Resistance to breakdown and creepage performance

Fiber Bragg grating sensors have good resistance to breakdown and creepage performance. It has undergone strict test evaluations such as 1575kV lightning impulse, 1525kV operational impulse, 400kV power frequency withstand voltage, and DC10-20kV 5-minute DC withstand test, and has successfully passed the above tests. This feature enables fiber Bragg grating sensors to work safely and reliably in high-voltage transformer environments, without breakdown or creepage due to high voltage, improving the safety of transformer temperature monitoring systems.

INNO температурни сензори со оптички влакна ,системи за следење на температурата.

INNO температурни сензори со оптички влакна ,системи за следење на температурата.