Fiberoptesch Temperatursensor, Intelligent Iwwerwachung System, Verdeelt Léngen OPTIC Hiersteller a China

|

|

|

1、 Overview of Substation Monitoring System

The substation monitoring system is an important component of the substation automation system, mainly used for real-time monitoring and control of the operation status of the substation to ensure its safe and stable operation. It relies on advanced technology and has multiple functions and features. Zum Beispill, the intelligent substation monitoring system can monitor data such as power factor and temperature to ensure normal operation. Its fault diagnosis and warning function can timely detect potential faults and issue warnings through the analysis of monitoring data, allowing operation and maintenance personnel to take timely measures to avoid accidents; The remote control function allows operation and maintenance personnel to remotely operate and adjust substation equipment, improving operation and maintenance efficiency; The data analysis and optimization function can analyze historical data and provide decision support for operational optimization to reduce costs; Simultaneously adopting advanced encryption technology and protective measures to ensure data and system security, preventing unauthorized access and attacks.

From the perspective of structural composition, the substation monitoring system has different hierarchical structures. It can generally be divided into interval layer, communication layer, and station control layer. The interval layer is a data acquisition, protection, and control device for equipment operating on site, such as comprehensive protection relays, protection control cabinets, multifunctional meters, etc. They are closely connected to primary equipment and are responsible for actual data acquisition and equipment control. The communication layer is a bridge for data transmission between the interval layer and the station control layer. Data is transmitted through communication cables/optical cables, with devices such as communication management machines and switches in between responsible for data distribution, transmission, and storage of raw data. The station control layer is usually regarded as the backend, including computers, printers, monitoring screens, and other devices. This layer needs to develop applications for the collected data to be displayed on the terminal screen. Remote control commands are also sent from this layer and sent to the interval layer for execution through the communication layer.

Zousätzlech, the substation monitoring system consists of two levels in terms of centralized monitoring and management of power and environment, namely the monitoring center and the monitoring site (which can also be designed as a multi-level monitoring center architecture according to requirements). The monitoring center consists of database servers, monitoring service desks, printers, and other equipment, responsible for data collection of monitoring devices across the network, statistical processing and analysis of device information, and providing various forms of alarms (such as sound and light, voice prompts, voice outbound calls, SMS, etc.); The monitoring site adopts high-performance IBSU intelligent station monitoring unit, which is responsible for collecting monitoring equipment parameters and processing intelligent device protocols in the substation. The collection equipment, intelligent air conditioning controller, intelligent battery detector, camera, sensor and other devices can be flexibly configured according to the site scale to monitor the power environment in the substation.

The substation monitoring system has diverse functions. The data acquisition and processing function obtains analog quantities (such as current, voltage, active power, reactive power, power factor, Frequenz, and oil), switch quantities (such as equipment action and alarm signals, on load tap changer position signals, etc.), electrical energy and other data through measurement and control devices and communication interfaces, including DC sampling (converting AC signals into DC voltage signals suitable for data acquisition unit processing through transmitters and connecting them to the data acquisition unit), as well as collecting electrical energy from remote transmission devices and DC monitoring devices through communication interfaces. The collected data will be processed and stored. It also has control operation functions, alarm and processing functions, sequence of events (SOE) and accident recall functions, remote control unit (RTU) functions, clock synchronization functions, human-machine communication and operation management functions, and interface functions with other devices.

As an important part of the power supply and distribution system, the substation monitoring system can achieve integrated monitoring, early warning, and auxiliary operation and maintenance of power, environment, safety, and other aspects. The system supports threshold customization, and auxiliary inspections can remotely monitor the operation status of the station building without the need for personnel to be on duty all day. It integrates station auxiliary subsystems to achieve comprehensive monitoring and internal and external intelligent scheduling. In case of sudden failures, it can timely understand the situation and command fault handling through video monitoring. These functions enable the station room to have fewer or no personnel on duty during operation, transforming the user maintenance mode from “passive repair mode” zu “active prevention mode”. It is widely used in substations, substations, switch stations, distribution rooms, box transformers and other scenarios, meeting the high-quality requirements of distribution network automation and preventing accidents.

2、 Temperature Monitoring in Substation Monitoring System

(1) The Importance of Temperature Monitoring

During the operation of the substation, the contact resistance of the electrical contacts of the primary equipment may increase due to factors such as equipment manufacturing, electric shock oxidation, and arc impact, leading to a temperature rise. When the temperature rises to a certain level, the mechanical and electrical strength of the equipment will decrease, and in severe cases, it can cause short circuits or even damage to the electrical equipment, seriously threatening the safe and stable operation of the power grid. Dofir, real-time monitoring of the temperature of electrical equipment in substations can help duty personnel detect problems as early as possible, eliminate hidden dangers, and ensure the safe operation of the power system.

(2) Traditional temperature monitoring methods and their drawbacks

The traditional temperature monitoring techniques for substations include infrared temperature measurement and wax sheet method. Infrared temperature measurement method utilizes the thermal effect principle of infrared radiation to determine the surface temperature of an object by detecting the infrared energy radiated by it. Allerdéngs, the measurement results of this method are greatly affected by environmental factors, such as high temperature, which can affect measurement accuracy and make it difficult to measure internal temperature. The wax sheet method involves attaching specially made wax sheets to the surface of equipment and determining whether the temperature exceeds a threshold based on the melting of the wax sheets. Allerdéngs, it can only provide a rough temperature range and has poor accuracy. Ausserdeem, most of these traditional methods require manual participation in device detection, which can easily lead to false alarms and missed detections. Due to the inability to conduct long-term continuous measurements, the accuracy and real-time performance of monitoring are poor.

(3) Application of Fiber Optic Temperature Measurement in Temperature Monitoring

1. Principle of Fiber Optic Temperature Measurement

Fiber optic temperature measurement system is a new technology that utilizes a certain characteristic of light propagation in optical fibers to achieve real-time measurement of spatial temperature field distribution. The optical fiber itself is a temperature sensor that can perform distributed continuous detection of temperature along the fiber optic path. It is mainly based on the principle of Optical Time Domain Reflectometry (OTDR) of optical fibers and the temperature effect of Raman Scattering in the back of optical fibers. When a light pulse enters an optical fiber from one end, it propagates forward along the fiber. Due to the mirror like inner wall of the fiber, every point of the light pulse during propagation will reflect, and a small portion of the reflected light will be directed away from the light source, which is known as back Raman scattering light. The intensity of backscattered Raman light is temperature dependent, and by detecting the intensity of backscattered Raman light, the temperature at each point along the fiber can be calculated.

2. Application of Fiber Optic Temperature Measurement in Substations

Fiber optic temperature measurement technology has broad application prospects in substations.

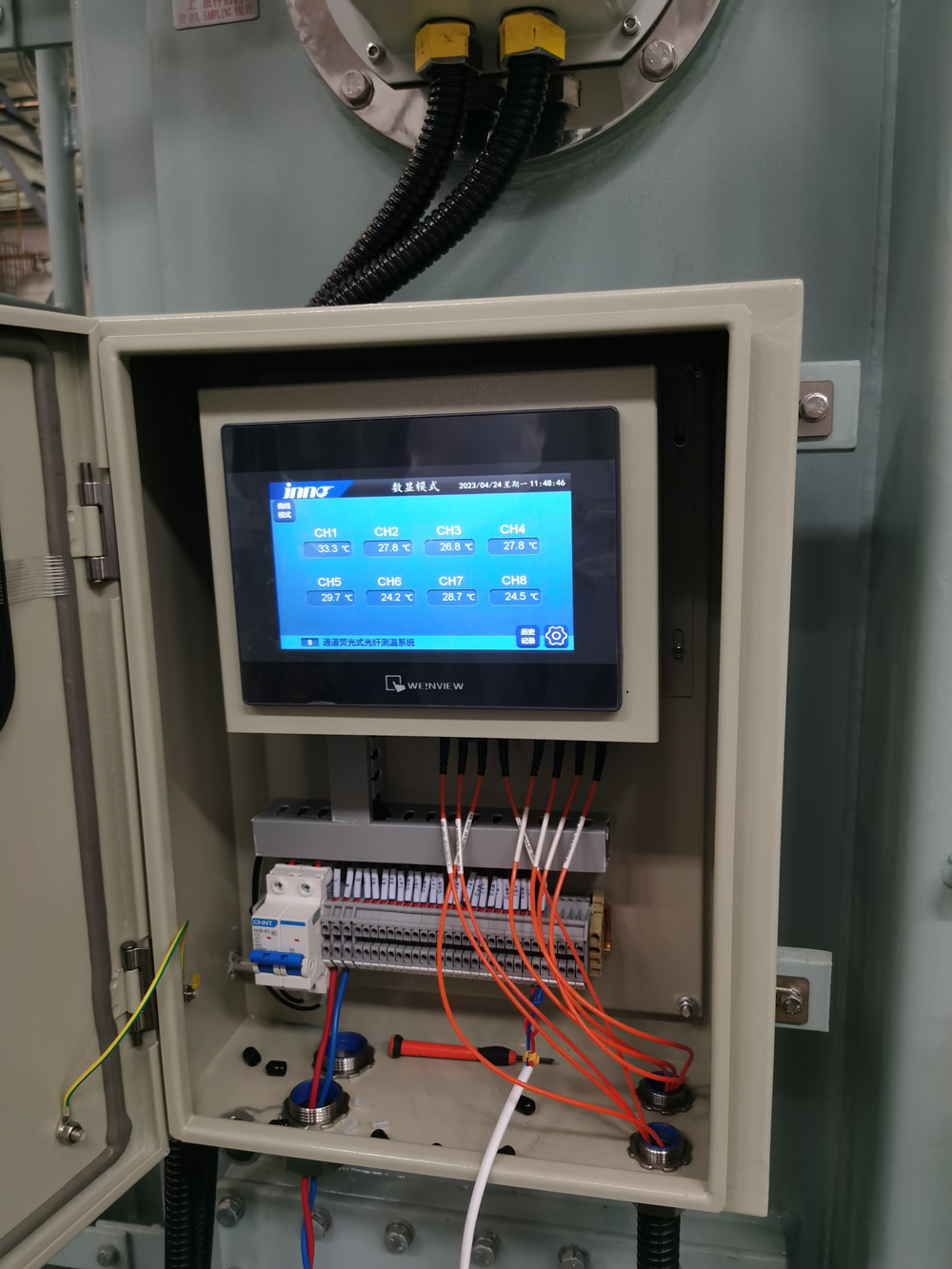

Equipment temperature monitoring: Fiber optic sensors can be installed on the surface of internal equipment such as transformers, Circuit breakers, and switchgear in substations to monitor equipment temperature in real time, detect abnormal situations in a timely manner, and avoid accidents caused by equipment overheating. Because fiber optic sensors have advantages such as corrosion resistance and strong electromagnetic interference resistance, they are suitable for temperature monitoring of equipment in complex electromagnetic environments such as substations. Zum Beispill, in a box type substation, fluorescent fiber optic temperature sensors can be placed at key locations such as transformers, Circuit breakers, and cables to monitor changes in ambient temperature in real time to ensure the normal operation of the equipment.

Cable temperature monitoring: Fiber optic sensors can be installed in cables to monitor cable temperature in real time and detect issues such as cable overheating and overload in a timely manner, ensuring the safety and stability of power transmission. For cables or high-voltage cable lines in the substation cable trench, due to the sensitivity of cable safety operation to temperature, the fiber optic temperature measurement system can perform distributed continuous measurement. Once there is a local abnormal temperature rise, it can quickly locate and provide accurate information for maintenance personnel.

3. Advantages of Fiber Optic Temperature Measurement

High precision: Fiber optic temperature sensors can achieve high-precision temperature measurement. Zum Beispill, the temperature measurement accuracy of fluorescent fiber optic temperature sensors can reach 1 ℃, which can meet the high requirements of substations for temperature measurement.

High response speed: Some fiber optic temperature sensors have a response speed of up to seconds, which can achieve real-time monitoring of rapidly changing temperatures. This allows for timely capture of temperature information in the event of sudden changes in the operating status of equipment in the substation.

Multi point monitoring: Fiber optic cables can be flexibly deployed at various equipment, bus connection points, cables, and other locations in the substation, enabling simultaneous temperature monitoring of multiple points in the substation and comprehensive understanding of the temperature distribution in the substation.

High safety and adaptability: Fiber optic itself is a non-metallic material with characteristics such as corrosion resistance and electromagnetic interference resistance. It can work stably in high voltage and strong electromagnetic interference environments such as substations, and will not cause additional interference to the electromagnetic environment inside the substation. Gläichzäiteg, there are no safety hazards such as electric shock. Zousätzlech, the transmission distance of optical fiber is relatively long, reaching tens or even hundreds of meters, which is suitable for temperature monitoring needs in large spatial layouts of substations.

3、 Voltage and current monitoring in substation monitoring system

(1) The Importance of Voltage Monitoring

Voltage is a key parameter in the operation of substations. The voltage level inside the substation directly affects the operation status of power equipment and the quality of electrical energy. If the voltage is too high, it may cause equipment insulation breakdown, overvoltage protection action, etc., shortening the service life of the equipment. Zum Beispill, transformers may experience iron core saturation under high voltage, resulting in additional losses and heat generation, affecting their normal operation. Allerdéngs, a low voltage can affect the normal functioning of power equipment, such as causing a decrease in motor torque and preventing the equipment from starting properly. Dofir, accurate monitoring of the voltage inside the substation is a necessary means to ensure the safe and stable operation of the substation and the normal supply of electrical energy.

(2) Voltage monitoring method

1. Direct detection method

The direct detection method is a relatively simple and direct voltage monitoring method. This method directly detects voltage by connecting electronic instruments such as oscilloscopes and voltmeters. Zum Beispill, in some laboratory environments or simple substation maintenance scenarios, an oscilloscope can be connected to measurement points in the circuit to visually observe the waveform and amplitude of the voltage. Allerdéngs, when using this method, special attention needs to be paid to selecting appropriate electronic instruments to ensure measurement accuracy and safety. Gläichzäiteg, certain modifications need to be made to the tested circuit in order to connect the voltage to the electronic instrument for measurement.

2. Sensor detection method

The sensor detection method converts voltage into a signal suitable for electronic measurement by installing specific types of sensors. Zum Beispill, in voltage monitoring of substations, electric field sensors can be used. Sensors can sense the electric field strength generated by voltage, convert the electric field signal into an electrical signal that can be recognized and processed by electronic measuring devices, and then obtain the voltage value based on the conversion relationship. This detection method is more suitable for high voltage scenarios where it is not convenient to directly connect measuring instruments, and can easily integrate sensors into automated monitoring systems for long-term continuous monitoring.

3. Transformer based monitoring scheme

In voltage measurement of substations, the characteristics of transformers can be utilized for voltage monitoring. In some substation control systems, the DC bus voltage monitoring of the frequency converter can be achieved through switching transformers. Zum Beispill, the primary voltage of a switching transformer is the bus voltage, and a set of windings is added to the secondary side as a sampling output of the bus voltage. The output voltage of the secondary side changes linearly with the change of the primary input voltage, which can both isolate strong and weak electricity and reduce voltage. Then, the sampled signal is processed and sent to the corresponding control chip, such as sending it to DSP for A/D sampling, to achieve various protection works.

(3) The Importance of Current Monitoring

Current monitoring in substations is equally crucial. The magnitude of current reflects the load situation of power equipment during operation, as well as the efficiency and effectiveness of power transmission. Excessive current can cause overload, heating, and even damage to power equipment. Zum Beispill, if a transformer is subjected to loads exceeding its rated current for a long time, it can cause the winding temperature to rise, accelerate insulation aging, and shorten equipment life. A too small current may indicate that the equipment is not functioning properly or there is a fault in the power transmission process (such as a broken line). Zousätzlech, accurate monitoring of the current magnitude of each branch and equipment in complex substation power grid structures is helpful for the scheduling and control optimization of the power grid, such as determining a reasonable flow direction for power distribution.

(4) The method of current monitoring

1. Direct detection method

Similar to the direct detection method of voltage, the direct detection method can also be used for current monitoring. Measure current directly by connecting electronic instruments such as ammeters. Allerdéngs, this method may be limited by instrument range when measuring large currents, and also requires appropriate modifications to the circuit in order to connect to the measuring instrument for measurement. It may be used in current measurement scenarios during the detection of small current branches or equipment debugging in substations.

2. Sensor detection method

The sensor detection method can use various types of sensors in current monitoring.

Magnetic field sensor: Based on the principle of current generating a magnetic field, the magnetic field sensor can detect changes in the magnetic field around the current and infer the magnitude of the current accordingly. In substations, magnetic field sensors are more suitable for non-contact measurement of high currents in busbars or large equipment. Zum Beispill, a Hall element is a magnetic field sensor that operates based on the Hall effect.

Current transformer: It is a device specifically used for current monitoring, and its basic principle is to use the magnetic field induction circuit in the current carrying coil to reduce the voltage of the detection signal through a transformation ratio. Widely used in substation monitoring systems. When using a current transformer, it is important to select the appropriate current transformer and perform appropriate circuit modifications to connect the current to the transformer for voltage transformation, and then measure and process the converted signal. Zum Beispill, when measuring the high current in high-voltage lines inside a substation, the high current is converted into a smaller current signal through a current transformer in a certain proportion, which is used for subsequent measurement, protection, and monitoring operations.

4、 Composition and Function of Substation Monitoring System

(1) Composition of Substation Monitoring System

1. Information collection system

This system includes various monitoring devices and data acquisition devices, mainly used to collect operational data and status information of various devices in substations, such as voltage, current, temperature, humidity, Drock, etc. When monitoring transformers, it is necessary to collect temperature related data such as oil temperature and winding temperature. Voltage transformers and current transformers are responsible for measuring voltage and current values, while various sensors (such as humidity sensors, pressure sensors, etc.) can monitor environmental humidity, pressure conditions inside equipment, etc. These collection devices collect data from various devices and environments in preparation for subsequent analysis and processing, and play a role as the data source in the entire substation monitoring system.

2. Data communication system

The data communication system is responsible for transmitting the data obtained by the collection system to other parts, ensuring the transmission of data between different devices and modules. The communication method can be wired communication, such as using communication cables, optical cables, etc. for data transmission. Zum Beispill, in fiber optic temperature measurement systems, data is transmitted through optical fibers; It can also be wireless communication, such as using ZigBee wireless network technology to transmit some sensor measurement data, such as temperature data collected by wireless temperature sensors, which can be transmitted to the control room host through ZigBee network. During the communication process, communication management machines, switches, and other devices participate in the distribution and storage management of data to ensure the efficiency and accuracy of data transmission.

3. Monitoring Center System

The monitoring center system is the core part of the substation monitoring system, mainly composed of database servers, monitoring service desks, printers and other equipment. The database server is used to store massive monitoring data collected from various devices in the substation, and to classify, store, manage, and query this data. The monitoring service desk provides an operation interface for operation and maintenance personnel. On this interface, operation and maintenance personnel can intuitively view the operating parameters, operating status, and other related monitoring information of substation equipment. If abnormal situations are found, they can be handled through this platform. Printers can be used to print important monitoring reports, data statistics, and other materials for operation and maintenance personnel to analyze and archive.

4. Control system

The control system includes various switches and actuators, which can achieve automatic control and scheduling of various equipment in the substation. Zum Beispill, when the current of a certain line in the substation is detected to be too high, the control system can disconnect the circuit breaker in the control circuit to avoid overloading and damage to the line. Zum Beispill, according to the voltage adjustment instructions given by the monitoring center, the control system can automatically operate the on load tap changer of the transformer, thereby achieving voltage adjustment to ensure the safe and stable operation of the substation.

5. Human machine interface system

The human-machine interface system serves as a window for operation and maintenance personnel to interact with the substation monitoring system, and its design requires simplicity, ease of use, and intuitive clarity. It can display the layout of substation equipment, equipment operation status (such as connection status, Operatioun, stop, fault status, etc.), monitoring data (displaying voltage, current, temperature, etc. in the form of charts, numbers, etc.) and other information in a graphical interface. Through this interface, operation and maintenance personnel can easily perform remote control operations on equipment (such as remote closing and opening operations), set monitoring parameters (such as temperature warning thresholds, voltage upper and lower limits, etc.), and view system alarm information (display equipment faults, parameter abnormalities, and other alarm information through sound, light, text prompts, etc.).

6. Power supply guarantee system

The power supply guarantee system mainly includes equipment such as UPS power supply and backup generator set. Its function is to ensure the stable operation of the substation monitoring system and prevent sudden events such as power outages from affecting the system. Due to the interruption of power supply in the substation, if the monitoring system cannot work properly, it will result in the inability to grasp the real-time operation status of the substation, which may cause various safety accidents. UPS power supply is rechargeable and backup during normal power supply. In case of power interruption, it can quickly provide temporary power support for monitoring system equipment. The backup generator set can provide continuous power supply to the substation monitoring system and other important equipment in extreme situations such as long-term power outages, to ensure the safe and stable operation of the substation.

(2) Functions of substation monitoring system

1. Data collection and processing functions

The substation monitoring system can collect various types of data, including analog quantities (such as voltage, current, power factor, temperature, etc.), switch quantities (such as equipment operation status conversion signals, protection device action signals, etc.), electrical energy (used to measure equipment electricity consumption, etc.), and other data. In terms of data collection, it can obtain data directly connected to devices through measurement and control devices. Zum Beispill, a multifunctional electricity meter calculates power factor, electrical energy, and other data by measuring basic parameters such as voltage and current of the line; Information from various intelligent devices, such as DC monitoring devices and remote transmission devices for electrical energy, can also be obtained through communication interfaces. The collected data will be processed accordingly, such as signal transformation and numerical conversion (such as converting the collected analog signal into a digital signal for computer processing) during the process of analog signal acquisition. The switch data will be processed for state judgment, displacement recording, etc. The processed data will be stored in the database server for subsequent query, analysis, and use.

2. Control operation function

The control system can control the equipment in the substation as needed. Zum Beispill, remote operation can be carried out, and operation and maintenance personnel can issue control instructions through the human-machine interface of the monitoring center system, which are transmitted to the equipment control device in the interval layer through the communication layer, so as to perform opening and closing operations on the switch equipment (such as circuit breakers, isoléierend Schalter, etc.) of the substation, adjust the on load tap changer of the transformer, and change the voltage level; Automatic control operations can also be carried out, such as limiting the preset working parameters such as voltage and current. When the actual operating parameters exceed the limit, the control system automatically adjusts the operation without manual intervention, such as automatically reducing the load of the transformer to avoid overload, adjusting the switching state of the capacitor to regulate reactive power to stabilize the voltage.

3. Alarm and processing functions

When the monitoring system detects abnormal equipment operation or data exceeding the normal set range, the system can promptly issue an alarm signal. There are various forms of alarms, including sound and light alarms, voice prompts, voice outbound calls, SMS notifications, etc. Zum Beispill, when the oil temperature of the transformer exceeds the set upper limit of the safe temperature, the monitoring center system will automatically trigger the sound and light alarm device to remind the on duty personnel in the station; Gläichzäiteg, alarm information can be sent to remote operation and maintenance personnel, management personnel, and other relevant personnel through voice call or SMS notification functions. Ausserdeem, the system can record detailed information about the alarm event during the alarm, such as the time of the alarm occurrence, equipment name, specific abnormal data, etc., in order to analyze the cause of the fault afterwards. With the development of intelligent technology, the system can also perform some preliminary emergency handling operations based on alarm information, such as automatically reducing equipment load, switching backup equipment, etc., to prevent further expansion of faults.

4. Event sequence of events (SOE) and accident recall function

This function can record events that occur in the substation in chronological order. The SOE function accurately records the precise time sequence of various events (such as equipment state transition events, protective device action events, etc.), which can be precise to millisecond or even finer time scales, which helps to analyze the development process of faults afterwards. The accident recall function allows the system to record the operational data and status of relevant equipment during a period of time before the occurrence of a fault event (which can be set according to system settings, such as minutes to hours before the fault), including voltage, current, equipment switch status, and other information, providing detailed data basis for analyzing the cause of the accident and formulating preventive measures. Zum Beispill, when a power outage occurs in a substation, the accident recall function can be used to query the load situation of the transformer, the current situation of each line, and the opening and closing status of equipment such as circuit breakers before the power outage, thereby assisting engineers in determining the starting event and chain reaction process of the accident.

5. Remote Terminal Unit (RTU) function

The substation monitoring system can achieve remote control function, transmitting various data (such as equipment operation status, measurement data, etc.) inside the substation to the higher-level dispatch center or remote monitoring center, and receiving control instructions from the higher-level. This function is very important in the centralized dispatching management of the power grid, so that the dispatching center can control the operation of multiple substations in real time, so as to achieve macro regulation and control of the substation. Zum Beispill, when there is an imbalance in the distribution of power load within the power grid area, the dispatch center can send instructions to the substation through remote control functions to adjust the output power of transformers or adjust the connection method of lines to balance the power load.

6. Clock synchronization function

It is very important to maintain clock synchronization between the various devices in the substation and with the entire power grid system. The clock synchronization function of the monitoring system can ensure that the event time recorded by all devices is consistent, providing accurate time basis for event sequence recording, fault analysis and other operations. This function is achieved through time synchronization devices such as satellite clock receivers, which enable the clocks of equipment in the substation to run according to a unified standard time, avoiding problems such as data recording confusion and difficulty in fault analysis caused by inconsistent clocks.

7. Human machine communication and operation management functions

The human-machine connection and operation management function provides operation and maintenance personnel with the means to manage and operate the substation monitoring system. In the human-machine interface system, operation and maintenance personnel can easily perform various operations, such as viewing equipment operating status, controlling equipment operation, setting monitoring parameters, receiving alarm information, etc. as mentioned earlier. Gläichzäiteg, it can also perform system operation management operations, including system settings (such as device numbers, communication parameters, etc.), user permission management (setting different personnel’s permission ranges for system operations), data backup and recovery management (regularly backing up monitoring data to prevent data loss, and performing data recovery operations when needed), etc., to ensure the reliable operation and reasonable use of the substation monitoring system.

8. Interface function with other devices

The substation monitoring system needs to achieve good interface connection with various other equipment inside the substation and external related systems. Within the substation, the monitoring system needs to interact and communicate with various primary equipment (such as transformers, busbars, switchgear, etc.) and secondary equipment (such as protection devices, measurement and control devices, etc.) to achieve monitoring and control of these devices. Externally, it may be necessary to interface with the power grid dispatch system, power metering system, environmental monitoring system, etc., for example, to interface with the power grid dispatch system to achieve data reporting and instruction reception, share electricity consumption and other data with the power metering system, and obtain environmental data around the substation from the environmental monitoring system (such as temperature, humidity, wind direction, wind speed, and other meteorological data that may affect the operation of the substation), in order to improve the overall operational efficiency, safety, and reliability of the substation.

INNO Glasfaser Temperatursensoren ,Temperatur Iwwerwachung Systemer.

INNO Glasfaser Temperatursensoren ,Temperatur Iwwerwachung Systemer.