Fiberoptesch Temperatursensor, Intelligent Iwwerwachung System, Verdeelt Léngen OPTIC Hiersteller a China

|

|

|

Fluorescent fiber optic temperature sensors demonstrate the advantages of anti electromagnetic interference, héich Volt Resistenz, long equipment life, real-time monitoring, safety and reliability in transformer temperature monitoring without the need for electrical connections.

Types of Transformer Temperature Sensors

There are various types of transformer temperature sensors, which can be classified according to different standards.

1、 Classified by measurement method

1.1 Contact temperature sensor

Thermocouple

Principle: Thermocouple is a sensor that uses the principle of potential difference generated by the connection of two different metals to measure temperature. Common types of thermocouples include K, J, T, E, and others. Zum Beispill, under different temperature environments, the thermoelectric potential difference at the junction of two different metals (such as copper and constantan) will change, and this potential difference has a specific relationship with temperature. By measuring this potential difference, the temperature value can be obtained. Thermocouples have the characteristics of fast response, high precision, and high reliability, and are widely used for temperature measurement in extreme environments such as high and low temperatures. In transformer temperature monitoring, if it is necessary to measure the high temperature situation of certain parts inside the transformer, thermocouples may be selected.

Thermistor

Principle: Thermistor is a sensor that uses the material’s thermal resistance effect to measure temperature. Common types include positive temperature coefficient (PTC) and negative temperature coefficient (NTC) thermistors. For NTC thermistors, as the temperature increases, their resistance value decreases; PTC thermistors, on the other hand, are the opposite. In transformers, thermistors can be used to monitor transformer oil temperature, etc. Due to their fast response speed, high accuracy, and good linearity, they can accurately reflect temperature changes.

Thermistor (RTD)

Principle: Thermistor is a sensor that uses the characteristic of material resistance changing with temperature to measure temperature. Commonly used sensors include platinum resistors and nickel resistors. Generally speaking, RTDs are more linear than thermocouples, and their resistance increases with temperature. In terms of transformer temperature monitoring, thermal resistors can be installed in the oil tank and other parts of the transformer to determine the temperature by measuring changes in resistance values, thereby monitoring the operating temperature of the transformer and ensuring that it operates within the normal range.

1.2 Non contact temperature sensor

Infrared temperature sensor

Principle: Infrared temperature sensor is a sensor that uses the infrared energy radiated by an object to measure its surface temperature. Commonly used sensors include pyroelectric infrared sensors and thermal imaging infrared cameras. It does not require direct contact with objects and measures temperature by detecting the infrared radiation emitted from the surface of the transformer. This type of sensor has the characteristics of non-contact, séier Äntwert, and wide measurement range, which is suitable for rapid detection and rough monitoring of the surface temperature of transformers. Zum Beispill, during the operation of transformers, the temperature of the outer shell surface can be quickly obtained from a distance to preliminarily determine whether there are abnormal conditions such as overheating in transformers.

2、 Classified by working principle

2.1 Resistance temperature sensor

Resistance thermometer and thermistor

This is a typical resistive temperature sensor that measures temperature based on the principle of resistance changing with temperature. As mentioned earlier, there is a certain functional relationship between the resistance and temperature of a thermistor (RTD). By measuring the resistance value and based on this relationship, the temperature value can be obtained. This type of sensor can achieve high-precision temperature measurement in transformer temperature measurement, which is very important for accurately monitoring the temperature condition of transformers.

Integrated temperature sensor

Integrated temperature sensors integrate temperature sensing elements, expansion circuits, compensation circuits, etc. onto a small chip, which has the advantages of good linearity, séier Äntwert, and standardized output. In the transformer temperature monitoring system, if a miniaturized, high-precision, and responsive temperature measurement component is needed, an integrated temperature sensor is a good choice.

2.2 Thermocouple sensors

Thermocouple based on thermoelectric effect

Based on the principle of thermoelectric effect, temperature is measured using the thermoelectric potential difference between two different metals. It is a common temperature measurement sensor that can be used for temperature measurement in different parts of transformers, such as winding temperature, in temperature monitoring. Different types of thermocouples (such as K-type, J-type, etc.) are suitable for different temperature ranges and can be selected based on the actual operating temperature range of the transformer.

2.3 Fiberoptesch Temperatursensor

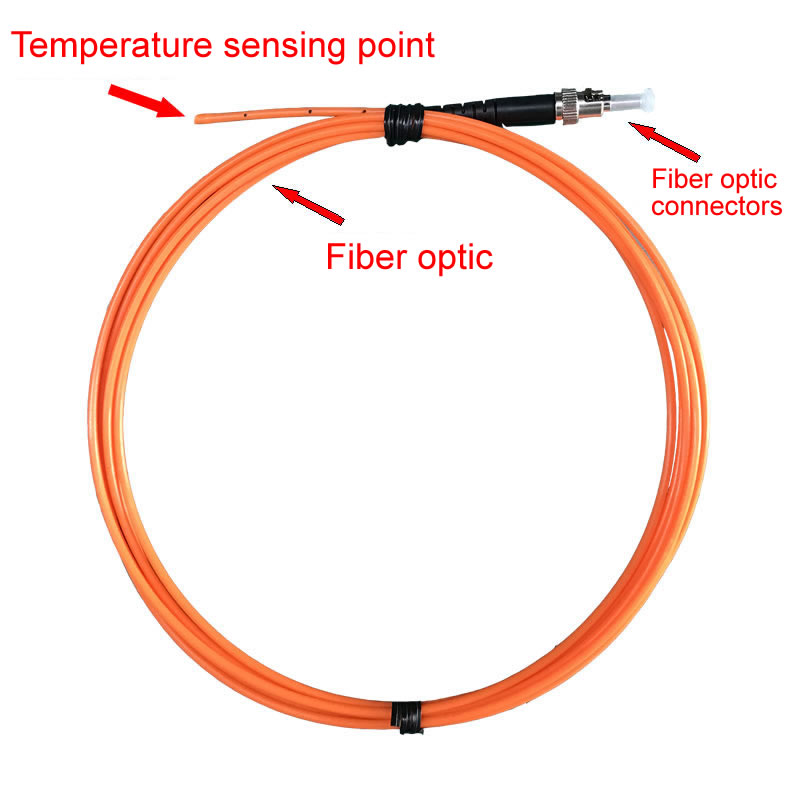

Fiber optic temperature sensors use the properties of optical signals in optical fibers to measure temperature. There are unique advantages in transformer temperature monitoring, such as fluorescent fiber optic temperature sensors.

2.4 Pressure and Temperature Sensor

This is a multifunctional sensor that can simultaneously measure temperature and pressure. Although it is rare to use pressure temperature sensors alone to measure temperature in transformer temperature monitoring, pressure temperature sensors may be used in some special transformer systems where both temperature and pressure factors need to be considered for their impact on transformer operation.

Virdeeler vun Fluorescent Fiber Optic Temperature Sensor in Transformer Temperature Monitoring

1、 Strong ability to resist electromagnetic interference

principle

There is a strong electromagnetic field environment around the transformer. When traditional temperature sensors (such as thermocouples, thermistors, etc.) measure, measurement probes and wires made of metal materials will generate induced currents under high-frequency electromagnetic fields. According to the skin effect and eddy current effect, induced current will cause the temperature of the sensor to rise, which will seriously interfere with temperature measurement, resulting in significant errors in temperature readings or inability to perform stable temperature measurements. The temperature measurement of fluorescent fiber optic temperature sensors is based on the characteristics of the optical signal in the fiber optic. Fiber optic is a non-metallic material that is not affected by electromagnetic fields and can accurately measure the temperature of transformers in strong electromagnetic field environments. Zum Beispill, in the operation of large power transformers, there are complex electromagnetic fields around them, and fluorescent fiber optic temperature sensors can work stably to ensure the accuracy of temperature measurement.

Advantages of application scenarios

In power facilities such as substations, there are numerous electrical devices that interact with each other and generate electromagnetic fields. Fluorescent fiber optic temperature sensors can accurately measure the temperature of transformers without interference from the electromagnetic fields of surrounding equipment. This is very important for ensuring the safe operation of transformers, as accurate temperature monitoring is one of the key factors in determining whether transformers are operating normally. If traditional sensors are used, the temperature status of the transformer may be misjudged due to electromagnetic interference, which can affect the judgment of the transformer’s operating condition and maintenance decisions.

2、 High precision measurement

Stable temperature dependence relationship

The fluorescence lifetime of a fluorescent fiber optic temperature sensor is stable in dependence on temperature and is not affected by factors such as excitation light intensity, fiber bending, or joint loss. This stability enables the sensor to provide high-precision measurement results when measuring transformer temperature. Zum Beispill, during the long-term operation of transformers, optical fibers may bend due to equipment vibration or installation layout, but this does not affect the measurement accuracy of fluorescent fiber temperature sensors. Allerdéngs, some traditional sensors may experience increased measurement errors due to external factors.

Compared to the accuracy advantages of traditional sensors

Compared with traditional temperature sensors such as thermocouples and thermistors, fluorescent fiber optic temperature sensors can provide more accurate temperature values when measuring transformer temperature. For important power equipment such as transformers, accurate temperature measurement helps to detect potential overheating issues in a timely manner. Zum Beispill, excessive temperature of transformer windings may cause insulation aging, short circuits, and other faults. Through high-precision measurement of fluorescent fiber optic temperature sensors, small changes in winding temperature can be detected in a timely manner, and measures can be taken in advance to avoid faults.

3、 High sensitivity

Quickly respond to temperature changes

Fluorescent fiber optic temperature measurement technology can achieve very high sensitivity and quickly respond to changes in transformer temperature. During the operation of transformers, the temperature may rapidly rise due to factors such as load changes and internal faults. Fluorescent fiber optic temperature sensors can capture these temperature changes in a timely manner. Zum Beispill, when there is local overheating inside a transformer, the sensor can quickly detect the increase in temperature and provide feedback to the monitoring system. This helps to take timely measures, such as adjusting the load, conducting troubleshooting, etc., to prevent further damage to the transformer.

Ability to detect small temperature changes

It can detect small changes in transformer temperature, which is of great significance for ensuring the stable operation of transformers. The normal operating temperature range of transformers is relatively narrow, and even small temperature deviations may be signals of potential faults. The high sensitivity of fluorescent fiber optic temperature sensors enables them to detect these small temperature changes, thereby improving the safety and reliability of transformer operation.

4、 Good insulation performance

Ensure the safety of transformer insulation system

Fluorescent fiber optic temperature sensors use optical fibers as the propagation medium for temperature sensing signals, and the optical fibers themselves have good insulation properties. In transformers, insulation performance is crucial because there is high voltage inside the transformer. The use of fluorescent fiber optic temperature sensors will not affect the insulation system of transformers. On the contrary, the sensor probe can be embedded in the tested equipment (such as transformer windings) to achieve accurate measurement of internal temperature. This helps to better monitor the temperature distribution inside the transformer and ensure the safe operation of the insulation system of the transformer.

The advantages of integrated design with transformers

The fluorescent fiber optic temperature sensor can be conveniently integrated with the transformer body for structural design. This not only simplifies the secondary information transmission circuit and improves the integration of intelligent components with the transformer body, but also ensures more effective temperature monitoring while ensuring transformer insulation. Zum Beispill, in the design of some new transformers, fluorescent fiber optic temperature sensors can be integrated into the internal structure of the transformer, making temperature monitoring more closely integrated with the operation of the transformer.

5、 Can be remotely monitored

The convenience of remote monitoring of transformer temperature

The fluorescence fiber optic temperature measurement system can achieve remote monitoring of the temperature of transformers. In large substations or distributed power systems, transformers may be distributed in different areas. By transmitting temperature signals through optical fibers, real-time temperature data of transformers can be obtained from remote monitoring centers. This greatly improves the convenience and efficiency of temperature monitoring for transformers, without the need for staff to inspect the temperature conditions of transformers one by one on site.

6. Withstand high voltage

The fiber optic lead out of the fluorescent fiber optic temperature sensor can withstand a power frequency voltage of 100KV for 5 minutes at a distance of 0.4m from the ground. This withstand voltage capability enables the sensor to operate safely in high voltage environments without damage or failure due to high voltage.

7. No need for frequent maintenance

Fluorescent fiber optic temperature sensors usually do not require frequent maintenance due to their simple structure and high reliability. This not only reduces operating costs, but also reduces downtime caused by maintenance and improves system availability.

The application value in smart grid

In the context of the development of smart grids, remote monitoring of transformer temperature is an important part of achieving intelligent management of the power grid. The remote monitoring characteristics of fluorescent fiber optic temperature sensors make them highly valuable for application in smart grids. Through remote monitoring, abnormal temperature conditions of transformers can be detected in a timely manner, and temperature data can be integrated and analyzed with other power grid operation data to achieve optimized operation and fault warning of the power grid.

INNO Glasfaser Temperatursensoren ,Temperatur Iwwerwachung Systemer.

INNO Glasfaser Temperatursensoren ,Temperatur Iwwerwachung Systemer.