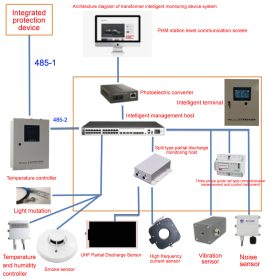

PHM Transformer Intelligent Online Monitoring Device system function

In the power supply system of urban rail transit, the power substation supplies power to various electrical equipment of the station, including environmental control equipment, communication equipment, comprehensive monitoring, water supply and drainage system, escalators, ಇತ್ಯಾದಿ. Its reliability is related to the safety and normal operation of the station. To ensure the safe and reliable operation of transformers in power substations, it is necessary to detect various parameter indicators during transformer operation in real time, and provide early warning and fault detection. The traditional operation and maintenance mode often adopts regular inspections and maintenance, which makes it difficult to detect and eliminate certain hidden faults in a timely manner, increases the risk of faults occurring during operation, and is highly likely to cause accidents. ಆದ್ದರಿಂದ, it is necessary to have real-time online intelligent comprehensive monitoring equipment continuously monitor the operation status and environmental status of the transformer equipment, timely and accurately detect various indicators of the transformer itself and the environment, conduct comprehensive intelligent analysis, give timely warnings when there are hidden dangers, accurately locate the hidden dangers, eliminate hidden dangers in the first time, and prevent accidents from occurring.

The PHM online monitoring system can monitor multiple indicators of transformers and their environment in real-time to determine the operational health status of transformers. Including: temperature of the winding and iron core of the transformer body, partial discharge detection of the transformer, vibration detection of the transformer, temperature and humidity detection of the operating environment of the transformer, transformer noise detection, instantaneous discharge arc detection of the transformer cable joint, and smoke detection. Communicate with station level communication chips through network fiber optic communication, IEC61850 protocol.

The main functions of the PHM online monitoring system are as follows:

| Equipment status monitoring | Measurement of coil temperature and iron core temperature (fiber optic temperature controller for dry-type transformers) Electrical connection point light mutation monitoring (arc light monitoring) Partial discharge monitoring |

| Environmental status monitoring | Operating environment temperature and humidity measurement Vibration monitoring during transformer operation Ground vibration monitoring Environmental noise monitoring |

| Local control function | Fan control Heating control Dehumidification control man-machine interface |

| Equipment Health Status Assessment | Operational risk assessment Warning information reminder |

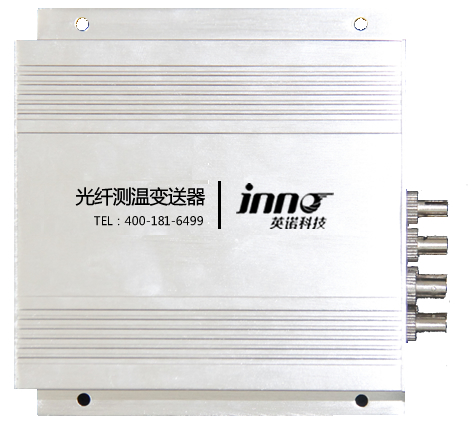

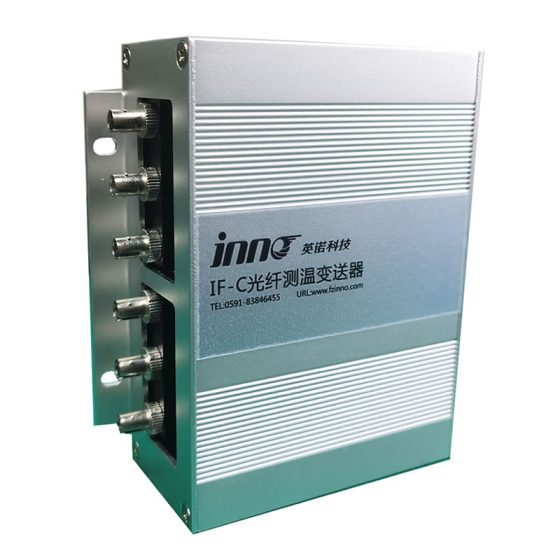

INNO ಫೈಬರ್ ಆಪ್ಟಿಕ್ ತಾಪಮಾನ ಸಂವೇದಕಗಳು ,ತಾಪಮಾನ ಮಾನಿಟರಿಂಗ್ ವ್ಯವಸ್ಥೆಗಳು.

INNO ಫೈಬರ್ ಆಪ್ಟಿಕ್ ತಾಪಮಾನ ಸಂವೇದಕಗಳು ,ತಾಪಮಾನ ಮಾನಿಟರಿಂಗ್ ವ್ಯವಸ್ಥೆಗಳು.