Fiber optic firikwensin zafin jiki, Tsarin sa ido na hankali, Rarraba masana'antar fiber optic a China

|

|

|

Why do reactors need temperature measurement? Reactor fiber optic temperature measurement system

Reactors are the main auxiliary equipment of long-distance transmission systems, playing an important role in power transmission due to their superior electrical performance. During the operation of a reactor, it is often due to external factors, internal structure, and other factors that the reactor may experience local temperature rise and overheating, ultimately leading to local burnout or even scrapping. This brings significant economic losses to the country and enterprises. Saboda haka, adopting a reactor fiber optic temperature measurement system and real-time monitoring of the internal temperature of the reactor is of great significance and practical value.

The reactor fiber optic temperature measurement adopts a fluorescent fiber optic temperature measurement device. The sensing probe of this device is made of imported quartz fiber, which has complete electrical insulation and is not affected by high voltage and strong electromagnetic fields. It is resistant to chemical corrosion and pollution, and has fast response speed, simple installation, and high temperature resistance. The backend software is used for real-time online monitoring.

Purpose of Reactor Fiber Optic Temperature Measurement System

When the reactor sends abnormal or faulty signals, the faulty area of the reactor heats up and the temperature rises. By monitoring the temperature, the operating status of the reactor can be determined, thereby achieving the goal of protecting the reactor.

Ordinary temperature measurement devices cannot measure the internal temperature of reactors. To solve this problem, our company’s developed fluorescent fiber optic temperature measurement system can solve this problem through its anti-interference and high-temperature and high-pressure resistance characteristics.

Design principles of fiber optic temperature measurement host for reactors

Ka'idar aiki

Ginin tsarin yana bin ka'idar aiki. A bisa aikace-aikace, ana la'akari da ci gaba da hangen nesa, da misali, samfurori masu ci gaba da balagagge da dandamali na ci gaba an zaɓi su don gina tsarin da ke da amfani kuma yana magance matsalolin aiki.

Ka'idar daidaitawa

Business applications have the characteristics of complex business, numerous processes, large amount of information, and multiple application levels. Through unified application function planning, consensus can be reached on business operations at the application level, guiding various business units to carry out business with unified standards.

The system software and hardware platforms and application development tools used in the construction of business applications should comply with national standards, ma'auni na Ma'aikatar Watsa Labarai, dacewa fasaha bayani dalla-dalla da bukatun na kamfanin.

Ka'idar daidaituwa

Bin manufofin sarrafa bayanai na tsakiya, gaba ɗaya shiryawa, gabaɗaya zane, da aiwatar da mataki-mataki, Tsarin aiwatarwa ya ƙunshi ƙa'idodi guda huɗu: jagoranci guda ɗaya, shiri guda ɗaya, m matsayin, da hadaddiyar kungiya da aiwatarwa.

Ka'idar dogaro

The software and hardware resources need to ensure the uninterrupted and reliable operation of the cable temperature measurement system for 7 × 24 hours. Saboda haka, it is necessary to equip a complete design of reliability measures to ensure the high reliability of system operation and fully consider the reliability requirements of key system applications.

Amintaccen tsarin tsaro

Wannan tsarin yana ɗaukar jerin amintattun matakan ɓoyewa, tare da ginannen ciki 64 bit encryption algorithm. Tsarin yana da tsaro mafi girma kuma yana iya hana kwararar bayanai da sata yadda ya kamata, tabbatar da tsaro, daidaito, da amincin bayanan tsarin, da hana ayyukan ma'aikata ba bisa ka'ida ba da kuma halaltaccen aiki na haramtacciyar aiki. A system may be used by multiple operators, and to ensure system security, hierarchical permission management is implemented. The system administrator authorizes operators with different usage permissions, and each operator can only perform various operations within the scope of permissions, resulting in higher system security.

Ayyukan aiki yana da sauƙi, m, kuma mai hankali sosai

The system provides most of the default data required during operation, and each operation conforms to the actual business workflow, avoiding repetitive operations by operators. Tsarin yana bincika halaccin bayanan shigarwa ta atomatik kuma yana ba da saƙon abokantaka don kurakuran mai aiki.

Reasonable system structure design, high degree of abstraction of program functional modules

It can be flexibly configured according to the changes in the actual situation of users and the various needs of different users, to maximize the satisfaction of user needs. There are various rate management and multi type table management functions for users to better use this system.

The system adopts a Web Service platform and a B/S architecture design, which is in line with the trend of application development.

Stable operation, reliable data, actual operation of thousands of systems, and over 200 new projects added each year.

Dandalin yana da sauƙin aiki, mai sauƙi don Master, kuma tsarin shigarwa yana da sauƙi. Ana iya samar da bayanai ta atomatik zuwa rahotanni daban-daban kamar yadda ake buƙata, inganta gudanarwa yadda ya dace.

Introduction to the installation of temperature measurement wiring for reactors

1.1 Tsarin tsari

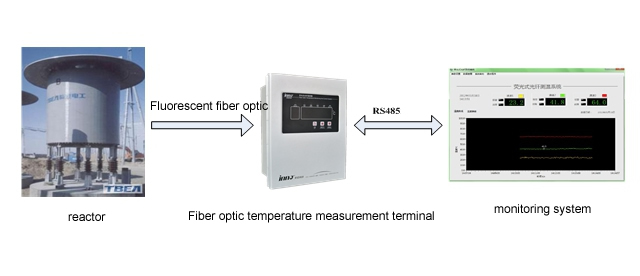

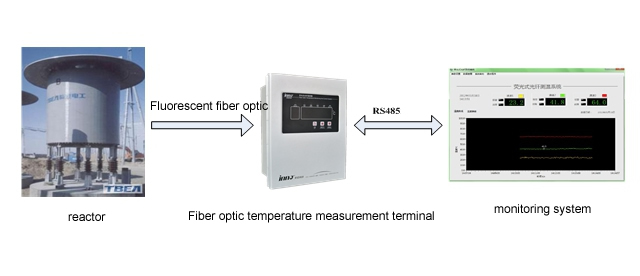

Tsarin ya ƙunshi sassa uku: mai kula da zafin jiki na fiber optic, mai kyalli fiber optic bincike, da software na sadarwa na fiber optic.

Reactor temperature measurement

Watsawar bayanai tsakanin tsarin baya da ma'aunin zafin jiki yana ɗaukar hanyar sadarwa ta RS485. Duk tarin bayanai, gudanarwa, kuma ana kammala nunin zafin jiki ta software na sadarwa, kuma tsarin ya fi fahimtar tattara bayanai da lura da ma'aunin zafin jiki. Tashar ma'aunin zafin jiki na fiber na gani yana haɗa filayen filaye masu kyalli masu yawa, samar da waje RS485 sadarwa, hana tsangwama, da ƙira mai jure lalata.

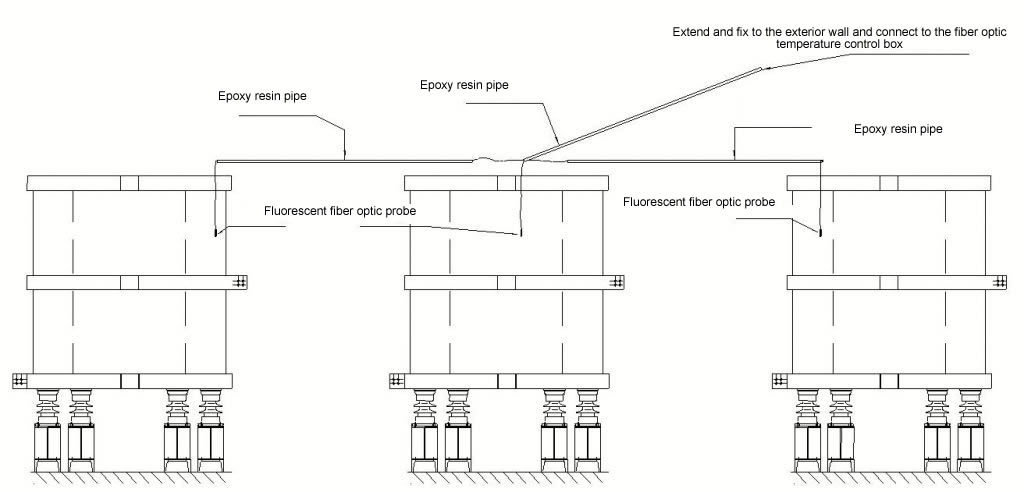

The fluorescent fiber optic temperature measurement terminal is embedded and installed in the box, and the outgoing fiber optic goes towards the upper part of the wall, which needs to exceed the height of the reactor. After passing through the epoxy resin pipe installed on the wall, the three fiber optic cables are combined and enter the B-phase reactor; The B-phase optical fiber is directly installed inside the inner airway wall of the reactor; A. The two phases of C are respectively introduced into the A-phase and C-phase reactors through overhead insulated epoxy resin pipes, and installed in the inner air duct wall of the reactor.

Application functions of fluorescent fiber optic temperature measurement system

Real time monitoring of fluorescent fiber optic temperature measurement system

Ana iya saita yawan tarin bayanai bisa ga bukatun abokin ciniki, kuma tsarin zai tattara bayanai akai-akai dangane da sigogin da aka saita. Sannan, za a nuna shi a cikin tsarin tebur ko zane mai lanƙwasa don cimma sa ido na ainihi. Sa ido na ainihi game da matsayin aikin kayan aiki; Real lokaci saka idanu da rikodin reactor zafin jiki.

Basic functions of fluorescent fiber optic temperature measurement system

1) Tambayar bayanan zafin jiki

Kuna iya tambayar bayanan zafin rana don takamaiman kwanakin, lilo, buga, da fitarwa zuwa Excel.

2) Ajiye bayanan zafin jiki na tarihi

3) Yi rikodin bayanan zafin jiki na dindindin

Safety Design of Fluorescent Fiber Optic Temperature Measurement System

The security of the system is crucial, therefore, in the design of the main station system, the security of the system should be fully considered to prevent unauthorized intrusion and leakage of confidential information. From the perspective of main station system security protection, the system provides security protection in both communication channels and system data.

Data security of fluorescent fiber optic temperature measurement system

Equipped with three-level security mechanisms at the operating system level, database level, and application software level.

Operating system level: Set different permission passwords on the network, non system administrators cannot operate servers and databases, and ensure system security and relative independence through routing, firewall, and other settings.

Database level: Set up demanders with different permissions and corresponding passwords in the database to ensure that unauthorized demanders cannot use data, and different demanders cannot use data beyond their level.

Application software level: Provides strict user login verification, permission control, and comprehensive management of event logs and operation records. System permission control includes functional permission control and data access permission control.

Function permission control:

The functional permission control system manages permissions from three dimensions: control objects, object operations, and operators. Based on this, it provides authorization methods for control object groups, operation groups, and operator roles. The accuracy of permission control can be determined to specific control objects and operators. The system determines the operation permissions of the login personnel based on these three dimensions.

The control objects of the system include system level nodes, terminal devices, da dai sauransu. Each control object has corresponding operations, and each authorization includes three parts: a control object group, an operation or operation group, and an operator role. In order to simplify and facilitate permission management, the system provides control object group permission inheritance.

The system provides a hierarchical authorization mechanism, which enables the system to have the ability of distributed permission management and solves the problem of overly complex permission management.

Data access permissions:

The data access permission control mechanism adopts the security audit mechanism provided by the database, providing data access user control, and providing log auditing for all data operations.

The original database only has query functionality, and the applications used only operate on the application database to ensure data security.

The system can store electricity consumption data with time markers and various analytical application calculation data, with a storage time of more than 2 years. Bugu da kari, the system has a powerful backup subsystem.

Detailed operation log records are available for all manual intervention data. The system design ensures high fault tolerance, and the database has three levels of data validation: field level, record level, and database level, ensuring the storage of illegal data.

Introduction to Fiber Optic Temperature Measurement Equipment for Reactors

1.1 Main features

The fluorescent fiber optic temperature controller is embedded installation. Wannan samfurin yana da fa'idodin fasaha na musamman a ma'aunin zafin jiki a cikin yanayi na musamman kamar babban ƙarfin lantarki, tsangwama mai ƙarfi na lantarki, da dai sauransu. Wurin zafi da siginar aunawa da ke karɓar ɓangaren firikwensin zafin jiki na fiber optic ba sa amfani da haɗin lantarki, wanda zai iya aiki tare da babban daidaito da kwanciyar hankali na dogon lokaci, sosai inganta aikace-aikace kewayon. A lokaci guda, the fiber optic temperature controller effectively eliminates the hidden dangers of local temperature rise and overheating that may occur during the operation of the reactor, ultimately leading to the burnout and scrapping of the reactor, which is not conducive to the safe operation of the reactor. Mai kula da zafin jiki na fiber optic yana da daidaitattun daidaito da azanci, yana da juriya ga babban matsi kuma ana iya sa ido a nesa, yana da tsawon rayuwa, karami ne a girmansa, yana sa gyaran kayan aiki mai sauƙi da dacewa, kuma yana tabbatar da sufuri lafiya. Its internal modular integrated design is aesthetically pleasing and reasonable.

1.2 Main functions

Can install an integrated multi-channel fluorescent fiber optic temperature measurement and demodulation instrument;

LED digital tube touring display of reactor hot spot temperature;

Provide RS485 communication interface to connect with upper computer instruments and provide temperature acquisition and transmission;

Fan start stop function, providing a pair of fan control output contacts (AC220V, 10A);

Over temperature alarm function, over temperature trip function, temperature control fault alarm function, each providing a pair of normally open output dry contacts.

INNO fiber optic na'urori masu auna zafin jiki ,tsarin kula da yanayin zafi.

INNO fiber optic na'urori masu auna zafin jiki ,tsarin kula da yanayin zafi.