Applicable scope:

Online monitoring of hot spot temperature in ring main cabinet plugs and box type substations;

Online monitoring of temperature at active cable joints.

The ring main unit is the main medium voltage equipment of the intelligent distribution room. Actual operating experience has shown that virtual connections, material aging, wear, overload, and other issues in cable joints or plugs can easily cause excessive contact resistance, overheating during operation, and ultimately lead to insulation burning, resulting in short circuits between lines or phases, instantly causing fire accidents;

The metal conductor inside the elbow cable joint of the ring main cabinet is the core component (insulation plug). Due to quality issues, assembly problems, harsh environments, and other issues of the cabinet body, poor contact of the contact parts can be caused, which can damage the insulation and conductivity performance of the joint. If not detected in a timely manner, it will cause overheating and burning of the joint, resulting in electrical accidents!

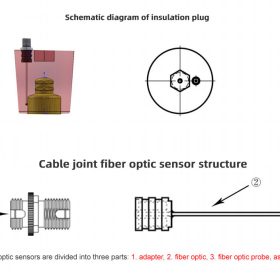

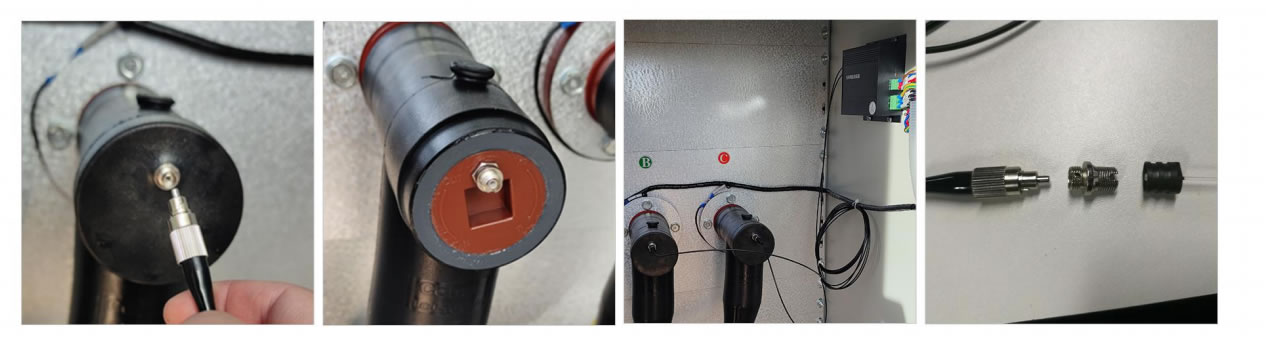

By using the pre embedded pouring method of fiber optic probes, the fluorescent fiber optic probe is poured into the insulation plug. Due to the good insulation performance of the fiber optic, the temperature measurement probe can be placed close to the metal copper part to directly measure the hot spot temperature. An uair sin, the temperature signal of the copper part is uploaded and monitored in real time through external fiber optic cables.

The fiber optic temperature monitoring system consists of three parts: fiber optic temperature transmitter, fiber optic adapter jumper, and cable head fiber optic sensor. The fiber optic sensor of the cable head is made of quartz fiber, and the temperature sensing end at the end contains temperature sensitive rare earth materials, which excite fluorescence after being irradiated by fixed wavelength light. One end of the fiber optic adapter is connected to the fiber optic sensor of the cable head, and the other end is connected to the fiber optic temperature transmitter. After the excitation of the fiber optic temperature transmitter stops, the excited fluorescence is resolved into temperature. The relationship between the decay time constant of the fluorescence afterglow and temperature is a class exponential function.

Product features:

Product features:

1. The fiber optic temperature sensor is embedded in the insulation plug of the T-shaped joint of the ring main cabinet. The fiber optic sensor directly contacts the metal part at the end of the plug, and monitors the temperature inside the T-shaped joint in real time;

2. The fiber optic sensor is embedded inside the product during the pouring of the plug, completely embedded with the plug, without changing the original form of the plug and cable head, and without reducing the performance of the cable head and the entire cabinet;

3. The plug and whole machine of the pre installed fiber optic sensor can pass the partial discharge test and withstand voltage test normally;

4. Fiber optic sensors have good flexibility, high physical hardness, are not easily damaged, and have a long service life;

5. Sensors can be customized according to needs, including: sensor length, probe type, sensor sheath material (ceramic, glass, plastic or other insulation materials);

6. Fiber optic temperature sensors have fast response, high accuracy and stability, insulation math, beatha seirbheis fhada, and are maintenance free;

7. The temperature signal output is a digital signal, which can be used for personalized applications in the background, such as alarms, warning notifications, sgrùdadh iomallach, etc. Temperature information can also be integrated into other systems.

8. The wireless communication part can be customized into modules based on different transmission protocols, supporting various transmission protocols such as IoT and smart grid.

INNO mothachaidhean teòthachd fibre optic ,siostaman sgrùdaidh teòthachd.

INNO mothachaidhean teòthachd fibre optic ,siostaman sgrùdaidh teòthachd.