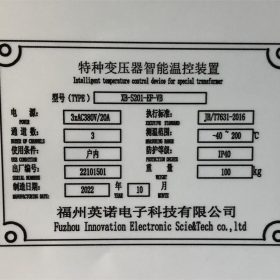

The intelligent measurement and control device for transformers is a temperature controller specially designed for dry-type transformers. The characteristics of this device are strong anti-interference ability, Gran capacidad de contacto de salida, Funciones completas, colorful LCD display interface with illustrations, Ajuste sencillo, y fácil operación; With reliable EMC, EMI performance. The temperature sensor can be customized and uses conventional PT100 temperature measurement. The intelligent temperature measurement device for dry-type transformers is installed on the ground. This product has unique technical advantages in temperature measurement in special environments such as high voltage and strong electromagnetic interference.

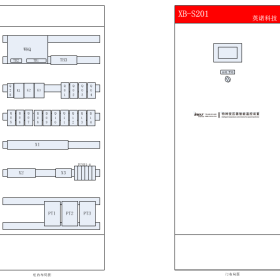

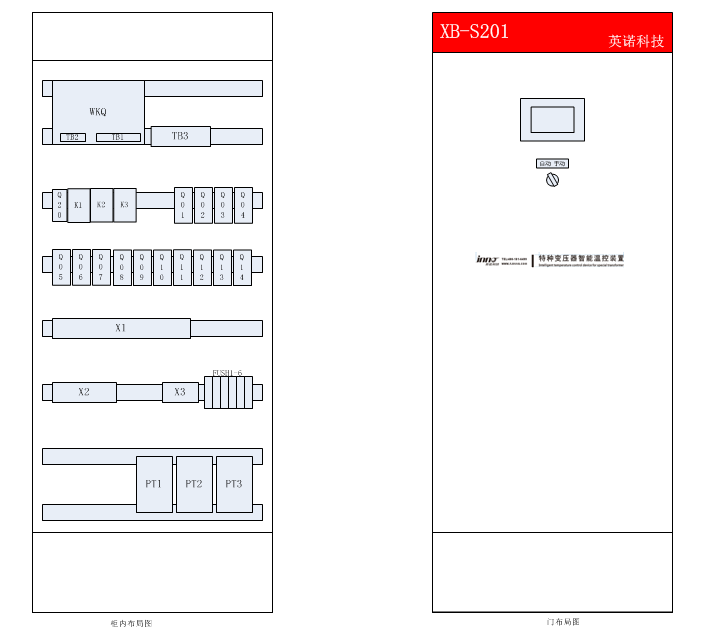

① The device has a maximum of 8 PT100 temperature measurement channels and a maximum of 2 PTC trip protection channels. Can be configured as needed.

② 1 RS485 communication channel, MODBUS RTU protocol.

③ 1-way fan control, default contact capacity 5A/250VAC, optional high power. The fan operation can be manually controlled by touching the buttons.

④ 1 door switch signal input.

⑤ 8-way relay output, can be used for door opening alarm output, over temperature alarm output, Salida de disparo por sobretemperatura, device fault alarm output, iron core alarm output, power loss alarm output, fan remote transmission output, fan fault output, output dry contact, contact capacity 5A/AC250V (optional 5A/DC220V). The specific configuration is based on the actual order and wiring diagram.

Product features

① The protection level is IP4x

② The contact output capacity is large.

③ Equipped with a 5-inch color LCD touch screen display.

④ The temperature controller uses an ARM architecture CPU with strong data processing capabilities and stable system performance.

⑤ The circuit board design concept of the temperature controller is modular design, con separación eléctrica fuerte y débil para evitar la diafonía espacial.

⑥ The temperature controller contains a clock chip and historical data storage with time markers.

⑦ RS485 communication function, communication protocol is the international open standard protocol Modbus RTU.

Dimensions of intelligent temperature measurement devices for special transformers

Método de instalación:Floor standing

Appearance dimensions:1500mmx600mmx400mmm (height x width x depth)

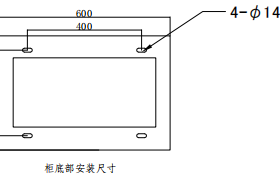

Bottom installation size: 300mm x 400mm (hole spacing) (installation holes 4x diameter 14)

Installation dimension diagram of XB-S201 special transformer intelligent temperature measurement device

Sensores de temperatura de fibra óptica INNO ,Sistemas de control de temperatura.

Sensores de temperatura de fibra óptica INNO ,Sistemas de control de temperatura.