Faseroptischer Temperatursensor, Intelligentes Überwachungssystem, Verteilter Glasfaserhersteller in China

|

|

|

Transformer temperature monitoring is crucial for ensuring the safe and stable operation of power systems and extending the service life of transformers; Fluorescent fiber optic sensors perform well in transformer temperature monitoring due to their high precision, Beständigkeit gegen elektromagnetische Störungen, und hohe Spannungsfestigkeit. They can monitor the internal temperature of transformers in real time and accurately, preventing overheating faults.

The Importance and Methods of Transformer Temperature Monitoring and the Advantages of Fluorescent Fiber Optic Sensors

1、 The Importance of Transformer Temperature Monitoring

1.1 Ensure the safe operation of equipment

Transformers play a crucial role in the power system, converting high-voltage electrical energy into low-voltage electrical energy. During operation, harsh environmental conditions and fluctuations in power load can cause the temperature of transformers to rise. If the temperature cannot be monitored in a timely manner, it may cause damage to the internal components of the transformer, leading to safety accidents such as fires. Through temperature monitoring, abnormal temperature increases can be detected in a timely manner, and measures can be taken to avoid accidents and ensure the safe operation of transformers.

1.2 Extend the service life of equipment

Excessive temperature can accelerate the aging of insulation materials and other components inside the transformer, shortening its service life. Continuous temperature monitoring helps to control the operating temperature of transformers within a reasonable range, reduce component losses caused by high temperatures, and thus extend the service life of transformers.

Ensure the stability of the power system

Transformers are the core equipment of the power system. Once a transformer malfunctions due to temperature issues, it may affect the stability of the entire power system, leading to power outages and other accidents. Timely temperature monitoring can provide early warning of potential faults and ensure stable power supply to the power system.

2、 Method for Monitoring Transformer Temperature

2.1 Traditional methods

Thermometer method

This method measures temperature by installing a thermometer on the transformer casing or a specific location. Zum Beispiel, common glass liquid thermometers, bimetallic thermometers, etc. Aber, this method can only measure the surface or local temperature of the transformer, and cannot accurately reflect the temperature situation of key internal parts (such as windings), and the accuracy is relatively low.

Thermocouple method

Thermocouples use the thermoelectric effect to convert temperature into a potential difference for measurement. Aber, thermocouples are susceptible to electromagnetic interference, and in environments such as transformers with strong electromagnetic fields, measurement accuracy may be affected. Überdies, their lifespan is limited and they need to be replaced regularly.

2.2 Modern Methods – Faseroptische Temperaturmessung (including Fluorescence Fiber Optic Sensor Temperature Measurement)

Verteilte Temperaturerfassung

Based on the backward Raman scattering effect of optical fibers, temperature distribution at different positions can be measured along the fiber. It can perform comprehensive and long-distance temperature monitoring on transformers, with advantages such as wide measurement range and high accuracy.

Fiber Bragg Grating Temperature Measurement

Fiber Bragg Grating is sensitive to physical quantities such as temperature and strain, and measures temperature by detecting changes in the grating’s reflection wavelength. It can achieve multi-point measurement and has good stability and anti-interference ability.

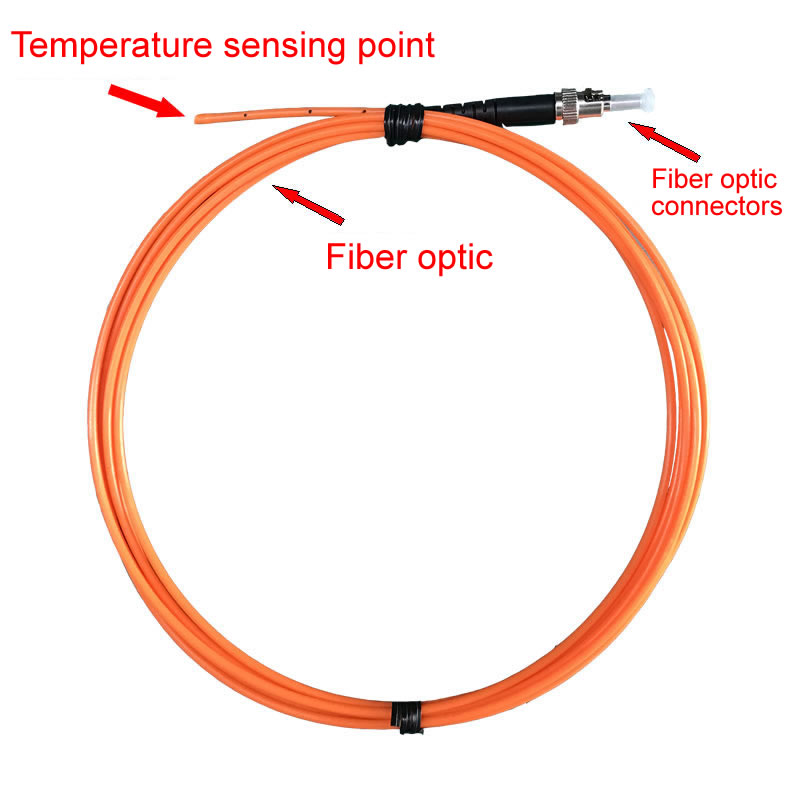

Fluorescence fiber optic sensor for temperature measurement

Principle: The basic principle of a fluorescent fiber optic sensor is to excite a fluorescent medium with blue violet light to produce fluorescence. The lifetime of the fluorescence decreases with increasing temperature, so the purpose of measuring temperature can be achieved by detecting the lifetime of the fluorescence. When the excited beam of light enters the winding, the fluorescent molecules will absorb the energy of the beam and emit a fluorescent signal. By measuring the lifetime of the fluorescent signal, the temperature of the winding can be indirectly determined.

Application in transformers: Fiber optic sensors can be installed on the heat sinks, windings, slip rings, and other parts inside the transformer to achieve all-round and multi-point temperature measurement. By combining fiber optic sensors with signal acquisition and processing systems, real-time monitoring of temperature changes in transformers can be achieved, fault risks can be predicted, and the normal operation of transformers can be ensured.

3、 Advantages of Fluorescent Fiber Optic Sensors

3.1 Strong ability to resist electromagnetic interference

In the operating environment of transformers, there is a strong electromagnetic field, and fluorescent fiber optic sensors are not affected by electromagnetic interference, avoiding the problem of measurement accuracy being affected by traditional temperature measurement methods (such as thermocouple methods) in this environment, and can stably and accurately measure temperature. It can work normally in complex electromagnetic environments both inside and outside transformers, making it particularly suitable for temperature monitoring of transformers in power systems.

3.2 High precision

Due to the high sensitivity of fluorescent materials to temperature changes, fluorescent fiber optic sensors can accurately measure temperature. Research shows that the accuracy of fluorescence temperature measurement for transformer windings can reach 0.1 degrees, which helps to more accurately monitor temperature changes in transformers, detect small temperature anomalies in a timely manner, and provide reliable basis for fault warning.

3.3 Comprehensive temperature measurement capability

It can achieve comprehensive temperature measurement of transformer windings and other parts, without being affected by local faults or complex working conditions, and can provide overall temperature distribution information of the transformer. Zum Beispiel, Innolux fluorescence temperature measurement technology can achieve comprehensive temperature measurement of transformer windings and real-time, continuous temperature monitoring, which helps to comprehensively understand the operating status of transformers.

3.4 Widely applicable environment

Fluorescent materials have strong durability and stability, and sensors can maintain high performance stability during long-term use. Suitable for a wide range of environmental temperatures, from as low as minus Baidu to as high as several hundred degrees Celsius, it can adapt to various harsh working environments that transformers may face, and can work normally in both high-temperature operating conditions and cold outdoor environments.

3.5 Quick Response

Fluorescent fiber optic temperature sensors have fast response times, can monitor temperature changes in real time, and respond immediately. This helps to capture sudden changes in transformer temperature in a timely manner, respond quickly to abnormal temperature conditions inside the transformer, and take timely measures to avoid the occurrence and development of faults.

INNO faseroptische Temperatursensoren ,Temperaturüberwachungssysteme.

INNO faseroptische Temperatursensoren ,Temperaturüberwachungssysteme.