Fiber optic temperatura sensor, Intelihenteng monitoring nga sistema, Giapod-apod nga fiber optic manufacturer sa China

|

|

|

The best fluorescent fiber optic nga pagsukod sa temperatura device should have the characteristics of wide application range, intrinsic nga kaluwasan, taas nga boltahe nga pagsukol, pagsukol sa electromagnetic interference, pagbulag, high precision, stable performance, long service life, ug uban pa. It is suitable for various industrial and scientific applications such as power equipment monitoring and harsh environment measurement. It can monitor temperature in real-time, provide accurate data, and has alarm and warning functions to ensure stable operation in complex environments.

1、 Overview of Fluorescent Fiber Optic Temperature Measurement

Device

Fluorescent fiber optic temperature measurement device is a device that uses fluorescence characteristics to measure temperature. It is mainly composed of multimode optical fibers and fluorescent objects installed on top of them. This device has a wide range of applications in various fields, such as temperature measurement of high-voltage instruments in electrical equipment, engine diagnostic systems, and temperature measurement between transformer windings; Temperature measurement in chemical processes such as highly corrosive environments or electrochemical treatment processes, and safe temperature measurement under microwave radiation heating; The fields of biology and medicine, such as temperature measurement during surgical procedures and research on physiological responses under electromagnetic radiation, play an important role.

2、 Working principle of fluorescent fiber optic temperature measurement device

The working principle of the fluorescent fiber optic temperature measurement device is based on the optical properties of fluorescent substances. When a fluorescent substance is excited by specific wavelength light radiation, it can produce a visible spectrum, also known as fluorescence. After stopping the irradiation, the fluorescence gradually disappears, and the gradually disappearing fluorescence is called afterglow. The decay time constant of fluorescent afterglow is a single value function of temperature, usually the higher the temperature, the smaller the time constant. As long as the value of the time constant is measured, the temperature can be calculated. Specifically, fluorescent substances emit fluorescence energy upon excitation by light of a certain wavelength (excitation spectrum). After the incentive is removed, the persistence of fluorescence afterglow depends on factors such as the characteristics of the fluorescent substance and environmental temperature. This excited fluorescence usually decays exponentially, with the decay time constant being the fluorescence lifetime or fluorescence afterglow time (ns). The detector can accurately measure the ambient temperature of the probe and provide monitoring and alarm by measuring the length of the fluorescence afterglow lifetime.

3、 Factors affecting the performance of fluorescent fiber optic temperature measurement devices

3.1 Characteristics of Fluorescent Substances

Stability of temperature dependence relationship

The stability of the dependence of fluorescence lifetime on temperature directly affects the measurement accuracy. If this relationship is unstable, there will be deviations in the correspondence between fluorescence afterglow time and temperature at different temperatures, leading to measurement errors. Pananglitan, in some precision industrial production processes, such as temperature monitoring in electronic chip manufacturing, even small temperature changes can affect chip quality. A stable temperature dependence relationship is necessary to ensure accurate temperature monitoring.

Long term stability

The long-term stability of fluorescent substances is also crucial for the performance of the device. Taking the fluorescence fiber optic temperature measurement device used for equipment monitoring as an example, if the performance of the fluorescent substance changes significantly over time, such as a decrease in fluorescence intensity or a change in the temperature correspondence of fluorescence afterglow time, the measurement accuracy and reliability of the device will decrease. Some devices may require long-term stable temperature monitoring, such as transformer monitoring in power systems, which requires fluorescent substances to maintain stable performance over many years of use. Some temperature sensitive substances in related systems are rare earth materials that are only sensitive to temperature, and their long-term stability has been fully verified, and the related systems have been successfully applied to device monitoring for more than 30 mga tuig.

3.2 Light source related factors

Stability of light source intensity

Although the principle of fluorescence fiber optic temperature measurement is that the temperature of the target being measured depends only on the time constant of the fluorescent material and is independent of changes in the intensity of the light source. Hinuon, in practical situations, if the intensity of the light source fluctuates too much, it may affect the accuracy of measuring fluorescence afterglow. Pananglitan, when the intensity of the light source suddenly increases or decreases, it may cause fluctuations in the fluorescence signal received by the detector, thereby interfering with the accurate determination of the fluorescence afterglow lifetime.

Accuracy of wavelength of light source

Excitation of fluorescent substances requires light of a specific wavelength. If the wavelength emitted by the light source is inaccurate, it may not effectively excite the fluorescent substance or the excitation efficiency may be low. This will result in weak fluorescence signals, which in turn will affect the accuracy of temperature measurement.

3.3 Fiber related factors

Fiber optic loss

Fiber optic cables generate losses during the transmission of optical signals, including absorption losses, scattering losses, ug uban pa. If the loss is too large, the fluorescence signal will be severely attenuated during transmission, and the signal strength reaching the detector will weaken, thereby affecting the accuracy of the measurement. Pananglitan, in long-distance fiber optic temperature measurement applications, fiber optic losses may accumulate, leading to increased temperature measurement errors at the remote end.

Fiber bending radius

The bending radius of the optical fiber in the fluorescent fiber temperature measurement device has certain requirements. If the bending radius is too small, it will increase the loss of the fiber and may even cause damage to the fiber. Especially in some scenarios where optical fibers need to be arranged in narrow spaces or bent for installation, such as temperature monitoring inside certain equipment, it is necessary to ensure that the bending radius of the optical fiber is within the specified range to ensure the normal transmission of fluorescent signals.

4、 Comparison of Fluorescent Fiber Optic Temperature Measurement Devices from Different Brands

4.1 Huaguang Tianrui

Technical research and cooperation

Fuzhou Huaguang Tianrui Optoelectronics Technology Co., Ltd. has established a deep cooperation between industry, academia, and research with Fuzhou University. A technology research team led by optical and electrical doctoral supervisors, with the participation of professors and graduate students, has been established with independent research and development as the main focus. Its fluorescent fiber sensing technology has reached an advanced level, and it has independently developed a series of fluorescent fiber temperature measurement products.

Product application areas

Its fiber optic temperature measurement technology, with its superior high insulation and strong anti-interference performance, solves the pain points of temperature measurement in many fields such as high-frequency microwave, high-voltage electrical, flammable and explosive, rail transportation, petrochemical, military and so on. The product can provide accurate temperature data in power transformers, cable lines, ug uban pang mga lugar, and can be used to monitor the hot spot temperature of transformer windings. Its application in dry-type transformers has the advantage of overcoming the shortcomings of existing temperature measurement technologies, such as overcoming the problem of short circuits caused by PT100 metal probes, which can obtain transformer temperature data more realistically and directly.

Product performance characteristics

The company’s fluorescent fiber optic temperature sensor has inherent insulation properties and can perform online temperature monitoring on components that withstand high voltage or high current. Pananglitan, it has applicability in temperature monitoring of equipment related to the State Grid, such as high-voltage switchgear, large oil immersed transformers, high-voltage reactors, ug uban pa.

4.2 Fuzhou Inno Tech

Product cost-effectiveness and functionality

Inno Technology’s fluorescence fiber optic temperature measurement system has high cost-effectiveness and reasonable price. Its products have unique technological advantages in temperature measurement in special environments such as high voltage and strong electromagnetic interference. The temperature hotspot of the fluorescent fiber optic temperature sensor used in the transmitter is not electrically connected to the measurement signal receiving part, which can work with high precision and stability for a long time, greatly improving its application range.

Product specifications and design

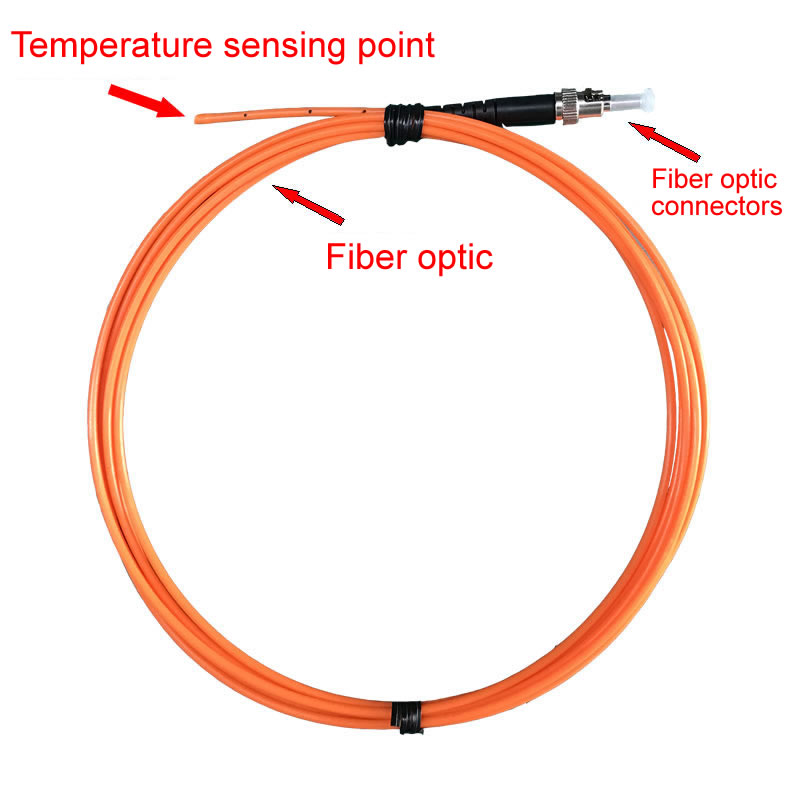

The fiber optic probe has a withstand voltage of 100KV (40mm withstand length, 5-minute withstand time), with 1-16 temperature measurement channels (expandable). The sensor type is quartz fiber optic, with a standard configuration of 5 metros (customizable for different lengths). The fiber optic probe consists of three parts: ST connector, fiber optic cable, and end temperature sensing end. Its design is reasonable, and the functions of each part are clear. Pananglitan, the end temperature sensing end contains temperature sensing rare earth material, which is used to generate optical signals containing temperature information. The fiber optic cable can withstand a high temperature of 200 ℃ as a whole, with an outer diameter of 3mm, a long-term bending radius of 13.2cm, a short-term bending radius of 4.4cm, and a ground distance of 0.4m from the fiber optic outlet. It can withstand a power frequency voltage of 100KV for 5 minutes.

Application Fields and Services

We provide comprehensive solutions and application services for temperature, pagkurog, pressure monitoring in various fields such as utility tunnels, mga pipeline sa lana ug gas, rail transit, electricity, municipal engineering, nukleyar nga gahum, bag-ong kusog, and chemical engineering. Collaborating with universities such as Fuzhou University, we have successfully developed a fluorescent fiber optic temperature sensor with independent intellectual property rights.

5、 Method and standard for selecting the best fluorescent fiber optic temperature measurement device

5.1 Measurement accuracy

Accuracy requirement matching

Determine the required measurement accuracy based on the actual application scenario. Pananglitan, temperature monitoring in the manufacturing process of electronic chips may require fluorescent fiber temperature measuring devices with an accuracy of ± 0.1 ℃ or even higher. In some industrial environments where temperature accuracy is not particularly high, such as temperature monitoring in ordinary chemical reaction vessels, an accuracy of ± 1 ℃ may be sufficient. If the accuracy of the selected device is lower than the actual demand, it may lead to quality problems or equipment operation risks during the production process; If the precision requirement is too high, it may increase unnecessary costs.

Accuracy stability

In addition to the accuracy value itself, the stability of accuracy is also important. During the long-term temperature monitoring process, the accuracy of the device should not have significant fluctuations. Pananglitan, in the long-term temperature monitoring of transformers in the power system, it is required that the temperature measuring device maintain an acceptable level of accuracy throughout several years or even decades of use to ensure accurate judgment of transformer load capacity and safe operation of equipment.

5.2 Sakup sa pagsukod sa temperatura

Meet the working temperature requirements

The temperature range varies greatly in different application scenarios. In the scenario of furnace temperature monitoring, it may be necessary to measure high temperatures of several hundred degrees Celsius, while in biomedical experiments, temperature monitoring may only require a temperature range near human body temperature. Busa, it is necessary to choose a fluorescent fiber optic temperature measurement device that can cover the temperature range of practical application scenarios. If the measurement range is too small to meet the measurement requirements in high or low temperature environments; A measurement range that is too large may increase unnecessary costs or reduce measurement accuracy within a specific temperature range.

Adaptability to special temperature environments

For some special temperature environments, such as those with rapid temperature changes or large temperature gradients, temperature measuring devices need to have good adaptability. Pananglitan, in the rapid cooling and heating stages of certain chemical processes or the starting and stopping processes of engines, temperature measuring devices should be able to accurately measure rapid temperature changes without being damaged or generating significant measurement errors due to rapid temperature changes.

5.3 Anti interference capability

electromagnetic interference

In many application scenarios, such as near electrical equipment such as high-voltage switchgear and transformers, there is a strong electromagnetic field. Fluorescent fiber optic temperature measurement devices need to have good electromagnetic interference resistance to ensure accurate temperature measurement. Pananglitan, in high-voltage substations, the electromagnetic field strength is very high. If the temperature measuring device has poor resistance to electromagnetic interference, it may cause fluctuations or errors in the measurement data, thereby affecting the judgment of the equipment’s operating status.

Chemical corrosion and environmental interference

In scenarios such as chemical production and marine environments, there may be chemical corrosive substances or environmental interference factors such as moisture and dust. The selected fluorescent fiber optic temperature measurement device should be able to resist these interferences and ensure normal working performance. Pananglitan, in the temperature monitoring of equipment on offshore oil platforms, the device should be able to resist the corrosion of seawater and the environmental effects of high humidity and high salinity.

5.4 Installation and usage requirements

Size and installation space

Select the appropriate size of fluorescent fiber optic temperature measurement device based on the actual installation space. In some temperature monitoring scenarios inside devices or small spaces, such as small electronic devices or precision instruments, small-sized temperature probes and compact device structures are required for smooth installation without affecting the normal operation of the equipment.

Flexible installation method

The installation method of the device should have a certain degree of flexibility and be able to adapt to different shapes, surface conditions, ug uban pa. of the tested objects. Pananglitan, for irregularly shaped objects or devices with uneven surfaces, the probe of the temperature measuring device can be easily installed and in good contact with the measured surface.

Convenience of operation and maintenance

Choose a fluorescence fiber optic temperature measurement device that is easy to operate and maintain. Pananglitan, the parameter settings of the device should be convenient and fast, and the troubleshooting and maintenance process should not be too complicated. In temperature monitoring systems for some large industrial equipment groups, if the operation and maintenance of temperature measuring devices are too cumbersome, it will increase labor costs and equipment downtime.

5.5 Cost factors

Equipment procurement cost

The procurement cost of fluorescent fiber optic temperature measuring devices with different brands and performance varies greatly. On the premise of meeting practical application needs, it is necessary to compare the prices of different products. Pananglitan, for small businesses with limited budgets or cost sensitive projects, they may prioritize products with relatively lower prices, but at the same time, they must ensure that the basic performance of the products meets the requirements.

Operation and maintenance costs

In addition to procurement costs, the operation and maintenance costs of the equipment should also be considered. Including energy consumption, regular calibration costs, and replacement costs for vulnerable parts. Pananglitan, some high-precision fluorescent fiber optic temperature measurement devices may require more frequent calibration, which will increase maintenance costs; If the replacement cost of vulnerable parts such as fiber optic probes in some devices is too high, it will also increase the overall operating cost.

INNO fiber optic temperatura sensors ,sistema sa pagmonitor sa temperatura.

INNO fiber optic temperatura sensors ,sistema sa pagmonitor sa temperatura.