Why does the bus duct need temperature measurement

Closed busbar trunking (abbreviated as busbar trunking) is widely used in power supply systems of high-rise buildings and buildings. But with the rapid increase in electricity consumption, the heating of the bus duct is particularly severe, especially at the connection head, which seriously affects the normal operation of the bus duct and requires real-time monitoring of electricity safety. Traditional temperature sensing cables have serious defects in the setting, quantification, تحديد المواقع, and reusability of temperature alarm points, which cannot meet the needs of production process management. لكن, high-precision point type thermometers or thermocouples cannot solve the needs of linear and continuous monitoring.

What are the advantages of distributed fiber optic temperature measurement systems

The distributed fiber optic temperature monitoring system adopts a brand new design, with good performance indicators and system stability. This system is developed based on the principles of backward Raman scattering and optical time-domain reflection (OTDR) تحديد المواقع, and has functions such as optical signal generation, spectral analysis, photoelectric conversion, signal amplification, and processing. The system uses dedicated temperature sensing optical cables as temperature sensors, integrating computer, fiber optic communication, fiber optic sensing, optoelectronic control and other technologies. It has inherent safety, مقاومة التآكل, and is not affected by electromagnetic interference. It continuously monitors long-distance and large-scale environmental temperature information.

Characteristics of Distributed Fiber Optic Bus Channel Temperature Monitoring System

Using distributed fiber optic temperature sensing equipment to sense cable temperature and position information for signal detection and transmission, تحقيق عدم الكشف عن الكهرباء والسلامة الجوهرية المقاومة للانفجار;

استخدام استشعار درجة حرارة الألياف البصرية الموزعة المتقدمة كوحدة قياس, مع التكنولوجيا المتقدمة ودقة القياس العالية:

تتميز الكابلات الضوئية الموزعة لاستشعار درجة الحرارة بنطاق درجة حرارة تشغيل طويل الأجل -40 °C إلى 150 °C, بحد أقصى 200 °C, ومجموعة واسعة من التطبيقات;

Adopting a detector single loop measurement method, simple installation and low cost; Can reserve spare cores;

عرض درجة الحرارة في الوقت الحقيقي في مناطق مختلفة, والقدرة على عرض البيانات التاريخية وتغيير المنحنيات, وكذلك متوسط التغيرات في درجات الحرارة:

النظام لديه هيكل مدمج, تركيب بسيط, وصيانة مريحة;

من خلال البرمجيات, يمكن ضبط قيم التحذير والإنذار المختلفة وفقا للمواقف الفعلية; طرق الإنذار متنوعة, بما في ذلك إنذار درجة حرارة ثابتة, إنذار معدل ارتفاع درجة الحرارة, وإنذار اختلاف درجة الحرارة.

من خلال البرمجيات, يمكن الاستعلام عن البيانات: استعلام نقطة بنقطة, استعلام سجل الإنذار, استعلام الفاصل الزمني, استعلام البيانات التاريخية, وطباعة التقارير.

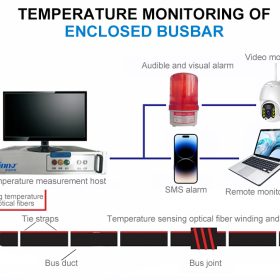

On site installation diagram of distributed fiber optic bus duct

|

|

|

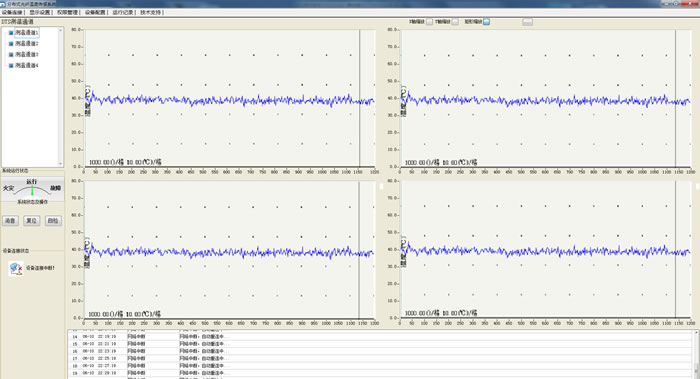

Distributed fiber optic temperature measurement software interface

Provide a user-friendly and easy-to-use fiber optic temperature monitoring application software. The software mainly includes functional modules such as temperature monitoring, fire alarm, and visual display.

Temperature curve display

The system can display the real-time temperature distribution curve of the entire optical cable, and when there is an abnormal temperature at a certain location, the curve can show whether the temperature at that location increases or decreases.

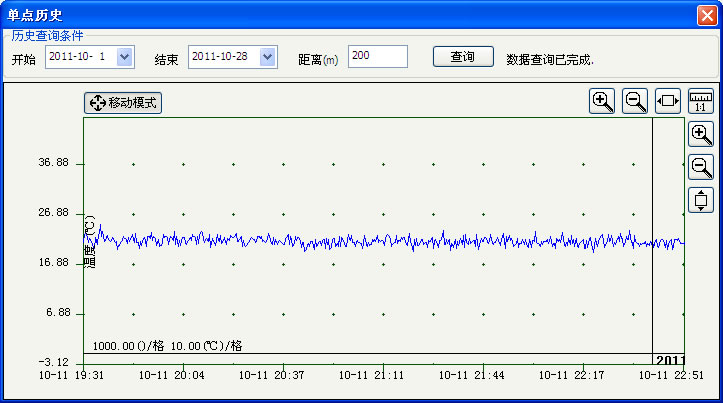

Historical temperature statistics

Provide historical temperature data statistical analysis function, provide temperature change trends, including:

(1) The temperature distribution curve at different positions of the cable at a certain moment;

(2) The temperature change curve of a cable at a certain point on a certain day;

(3) The temperature change curve at a certain point of the cable during a certain period of time;

(4) The curve of the highest temperature change on a certain day.

Over temperature alarm

Provide various flexible fire alarm methods such as fixed temperature, temperature rise, and regional temperature difference, and the alarm parameters can be graded and set by region. When the measured temperature exceeds the threshold temperature, the system will automatically emit alarm signals such as sound, LED indicator lights, text, and images. If multi-level temperature alarm (such as initial alarm at 30 °C, pre alarm at 40 °C, and measures taken at 50 °C) and temperature rise rate can be set, temperature correction can be made according to different environments. The set value of temperature rise rate can be determined by on-site monitoring.

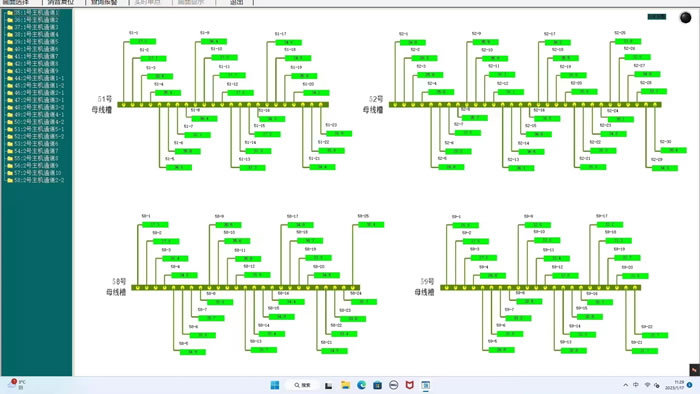

Visual interface

Provide a visual display interface that maps the fiber optic position to the image through a graphical configuration module. Once a temperature anomaly occurs at a certain point of the fiber optic, the alarm information is directly displayed on the image, making it visually appealing.

|

|

|

مستشعرات درجة حرارة الألياف البصرية INNO ,أنظمة مراقبة درجة الحرارة.

مستشعرات درجة حرارة الألياف البصرية INNO ,أنظمة مراقبة درجة الحرارة.