The BWY-802 and 803 series temperature controllers adopt the composite sensor technology, ማለት ነው።, the instrument temperature packet pushes the elastic element and simultaneously outputs the Pt100 thermal resistance signal. This signal can be remotely sensed to the remote control room, and the transformer oil temperature can be synchronously displayed and controlled through the XMT digital display temperature controller. The Pt100 thermal resistance signal can also be converted to the DC standard signal (0~5) V, (4~20 mA) and RS485 communication interface output with the computer Internet through the digital display instrument.

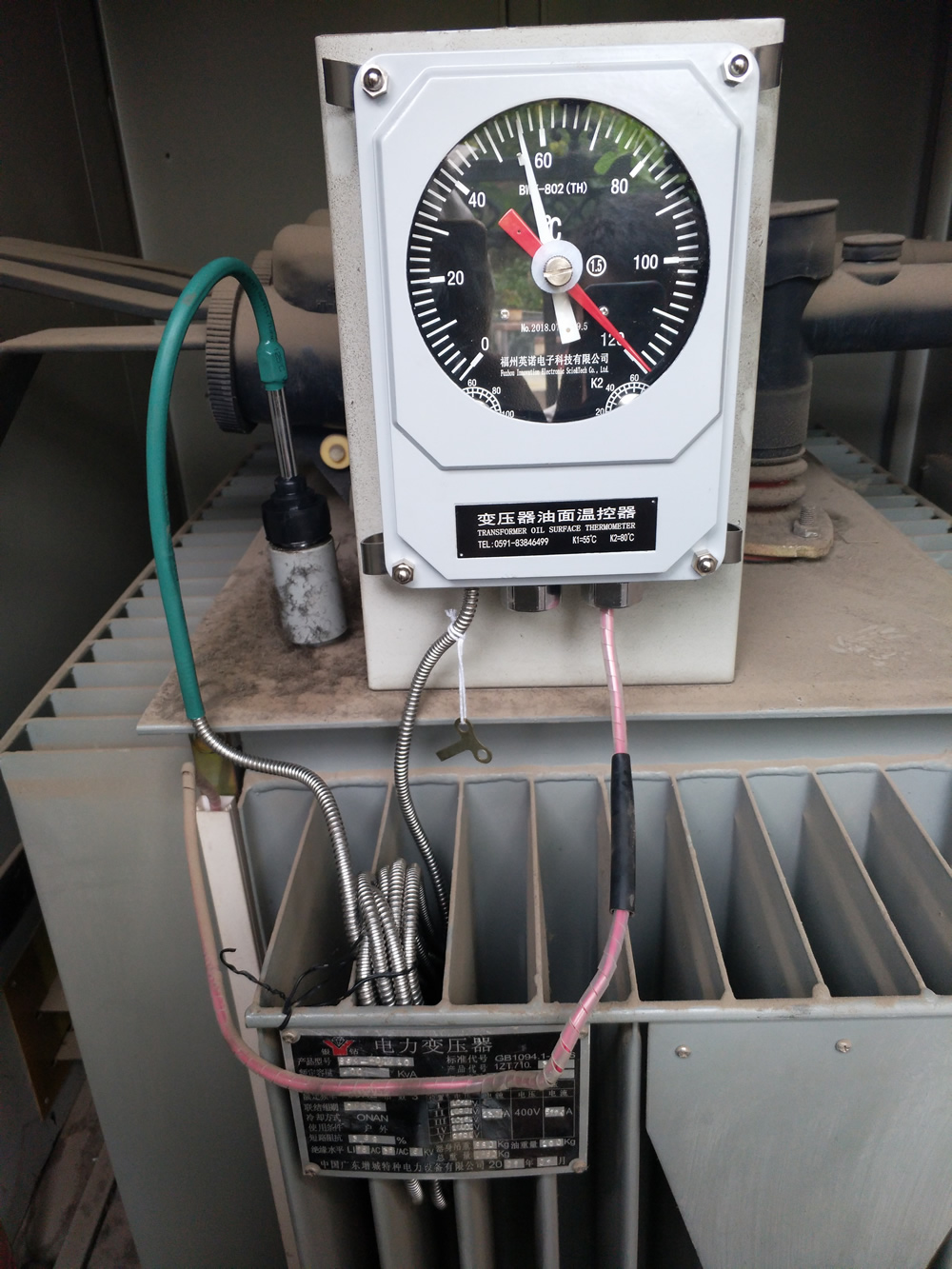

Introduction to Oil Level Temperature Controller for Oil Immersed Transformers

The BWY series transformer oil surface temperature controller is designed specifically for measuring and controlling the top oil temperature of transformers. The instrument has good protective performance and can be used normally for a long time under outdoor conditions. The instrument is equipped with three sets of adjustable temperature switches, which are used for starting multiple cooling systems, overheating alarms, ወዘተ. በተመሳሳይ ሰዓት, the temperature signal can be remotely transmitted to the computer system to achieve synchronous display and control of transformer temperature.

የሙቀት መቆጣጠሪያው የሥራ መርህ እንደሚከተለው ነው

The temperature controller mainly consists of elastic elements, capillaries, and temperature sensing packages. The sealing system composed of these three parts is filled with temperature sensing medium. When the temperature changes, the volume of the temperature sensing medium inside the temperature sensing component also changes. This volume increment is transmitted to the elastic element inside the instrument through a capillary tube, causing a corresponding displacement. After being amplified by the mechanism, this displacement drives the pointer to indicate temperature changes and drives a micro temperature switch to control the corresponding cooling system, achieving the goal of controlling the temperature rise of the transformer.

Real time shooting of temperature controller on-site cases

|

|

INNO የፋይበር ኦፕቲክ ሙቀት ዳሳሾች ,የሙቀት መቆጣጠሪያ ስርዓቶች.

INNO የፋይበር ኦፕቲክ ሙቀት ዳሳሾች ,የሙቀት መቆጣጠሪያ ስርዓቶች.